Absolutely, we accommodate projects of all sizes efficiently.

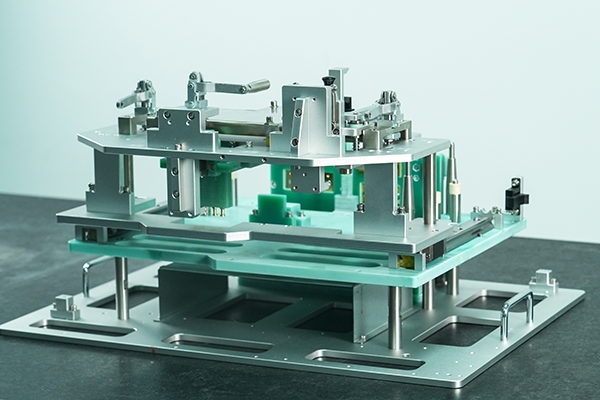

Our expert team designs and manufactures precise jigs and fixtures tailored to your production needs. These tools enhance accuracy and efficiency, streamlining your manufacturing process. With a focus on durability and performance, our custom solutions ensure consistent quality and improved productivity across various industries.

Jigs and Fixtures Design and Production used to hold and support parts during machining processes. They enhance precision, reduce errors, and improve efficiency. Our design and production services ensure that each jig and fixture is tailored to meet your specific requirements, promoting higher accuracy and faster production times.

We specialize in designing and manufacturing custom jigs and fixtures that streamline your operations and boost consistency. Our engineering experts work closely with you to create durable, precision tools that minimize setup times and guarantee accurate part alignment, driving improved productivity throughout your manufacturing process.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

6061

7075

2024

D2

A2

O1

1018

1045

1020

304

316

17-4 PH

C360 Free-Cutting Brass

C464 Naval Brass

Delrin (Acetal), Nylon 6/6

UHMW

Gray Cast Iron (Class 30, Class 40)

Ductile Iron (Grade 60-40-18)

Grade 2 (Commercially Pure)

グレード 5 (Ti-6Al-4V)

We provide custom design and manufacturing of jigs and fixtures that optimize your workflow and improve manufacturing consistency. Our engineering team collaborates with you to develop durable, precision-made tools that reduce setup time and ensure exact part positioning, enhancing overall productivity.

Provides mild corrosion protection and a non-reflective matte black finish. Common for steel jigs and fixtures to reduce glare and prevent rust.

Applies a thick, hard chromium layer for exceptional wear resistance and low friction. Ideal for sliding or high-contact fixture components.

A heat treatment process that diffuses nitrogen into the surface to improve hardness and fatigue strength. Widely used for steel fixture components requiring high surface durability.

Improves surface hardness while retaining a tough core, making it perfect for fixtures requiring high surface wear resistance with internal strength.

Adds a thick, durable protective layer with excellent wear and corrosion resistance. Often applied to fixture frames and larger jig assemblies for long-term use.

Enhances corrosion resistance and surface hardness of aluminum parts. Ideal for lightweight, corrosion-resistant fixture components.

Provides uniform coating, excellent corrosion resistance, and moderate hardness without an electrical current. Suitable for complex-shaped tooling components.

Offers corrosion resistance and improves lubricity on ferrous parts. Common for jigs and fixtures exposed to oily or wet environments.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

Jigs and Fixtures design and production services enhance precision, efficiency, and repeatability in manufacturing. Our engineers work closely with you to assess part geometry, materials, and tolerances. The result is a tailored solution that aligns seamlessly with your production goals.

We begin with a consultation to understand your production needs, part dimensions, and machine specifications. This step allows us to identify potential challenges and design solutions that will optimize your workflow.

Using advanced CAD (Computer-Aided Design) software, we create detailed models of your jigs and fixtures. These 3D models provide a virtual representation of the tools, allowing for easy modifications and adjustments before moving to production. This stage helps visualize the final product, ensuring everything is accurate and functional.

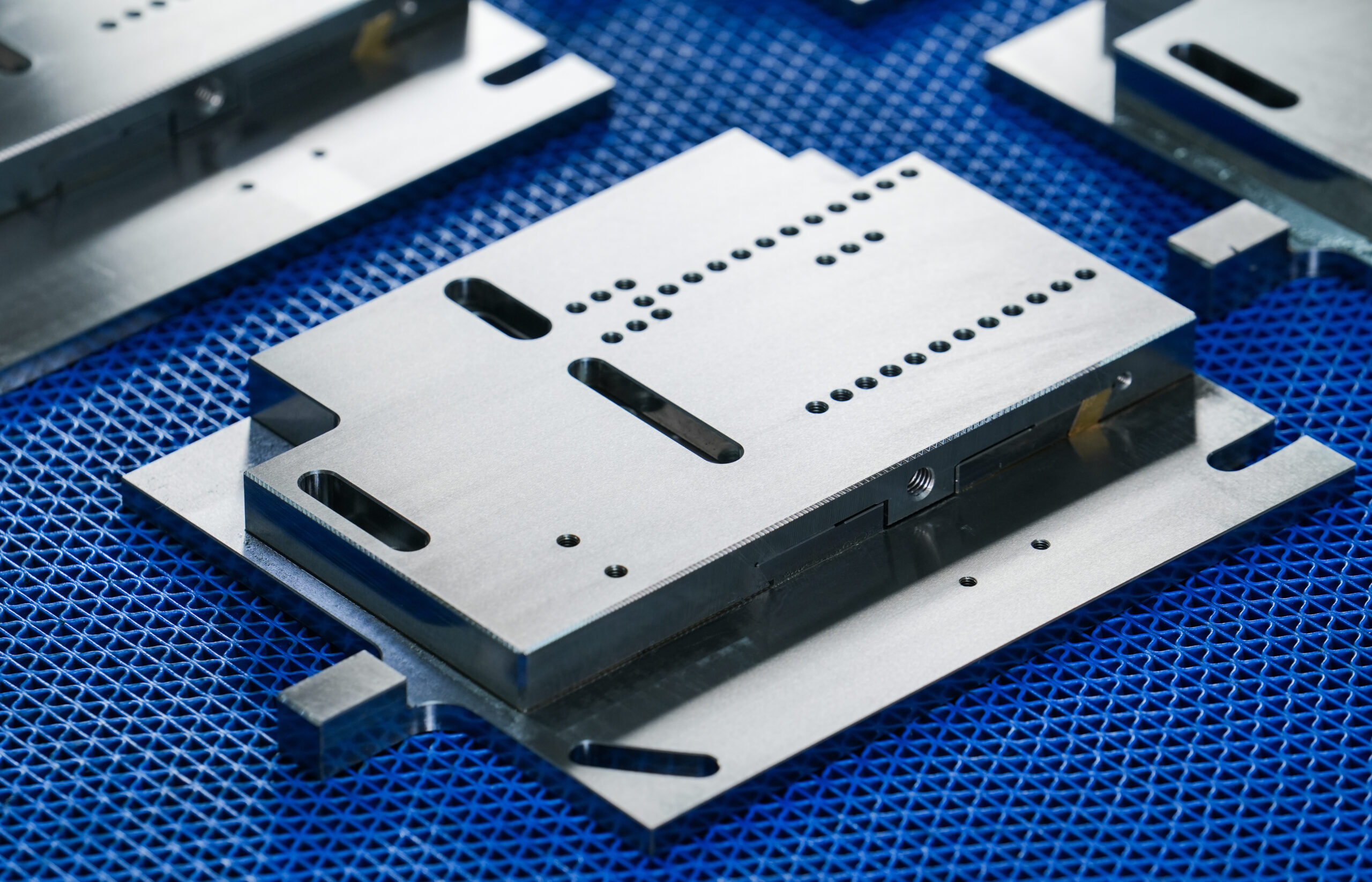

The selection of materials is critical to the durability and performance of jigs and fixtures. Depending on your production requirements, we offer a range of materials, from steel and aluminum to high-strength composites, ensuring that the tools can withstand high-pressure, high-temperature environments without compromising performance.

Once the design is finalized, the next step is manufacturing. At this stage, cutting-edge technologies come into play, ensuring that your jigs and fixtures meet the highest standards of quality and precision.

One of the core technologies used in the production of jigs and fixtures is CNC加工. With multi-axis CNC machines, we can achieve precise cuts, shapes, and complex features with high accuracy. This technology allows us to create tools with tight tolerances, ensuring perfect alignment and repeatability across batches. CNC machines can work with a wide range of materials, providing flexibility and adaptability in the production process.

To speed up the design process, we often use 3Dプリンティング for rapid prototyping. This allows us to quickly produce a physical version of the jig or fixture, enabling immediate testing and iteration before final production. Using 3D printing, we can also produce parts with intricate geometries that might be challenging with traditional manufacturing methods.

After the initial manufacturing process, we apply surface finishing techniques like grinding, polishing, or coating to enhance the durability and appearance of the jigs and fixtures. These finishes reduce wear and tear, prevent rust, and ensure that the tools are as smooth and precise as possible, improving the overall performance of your production line.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Do you handle low-volume and high-volume production tooling?

Absolutely, we accommodate projects of all sizes efficiently.

Are your jigs compatible with automated systems?

We design jigs and fixtures that can integrate with both manual and automated workflows.

Can jigs and fixtures be modified after production?

Yes, we provide redesign and modification services as needed.

How long does it take to produce a jig or fixture?

Production times vary but prototypes typically ship within weeks.

Can you design jigs for complex assemblies?

Yes, our engineers specialize in custom designs for even the most complex manufacturing needs.