Yes, we can provide deburring, cleaning, and secondary machining if required.

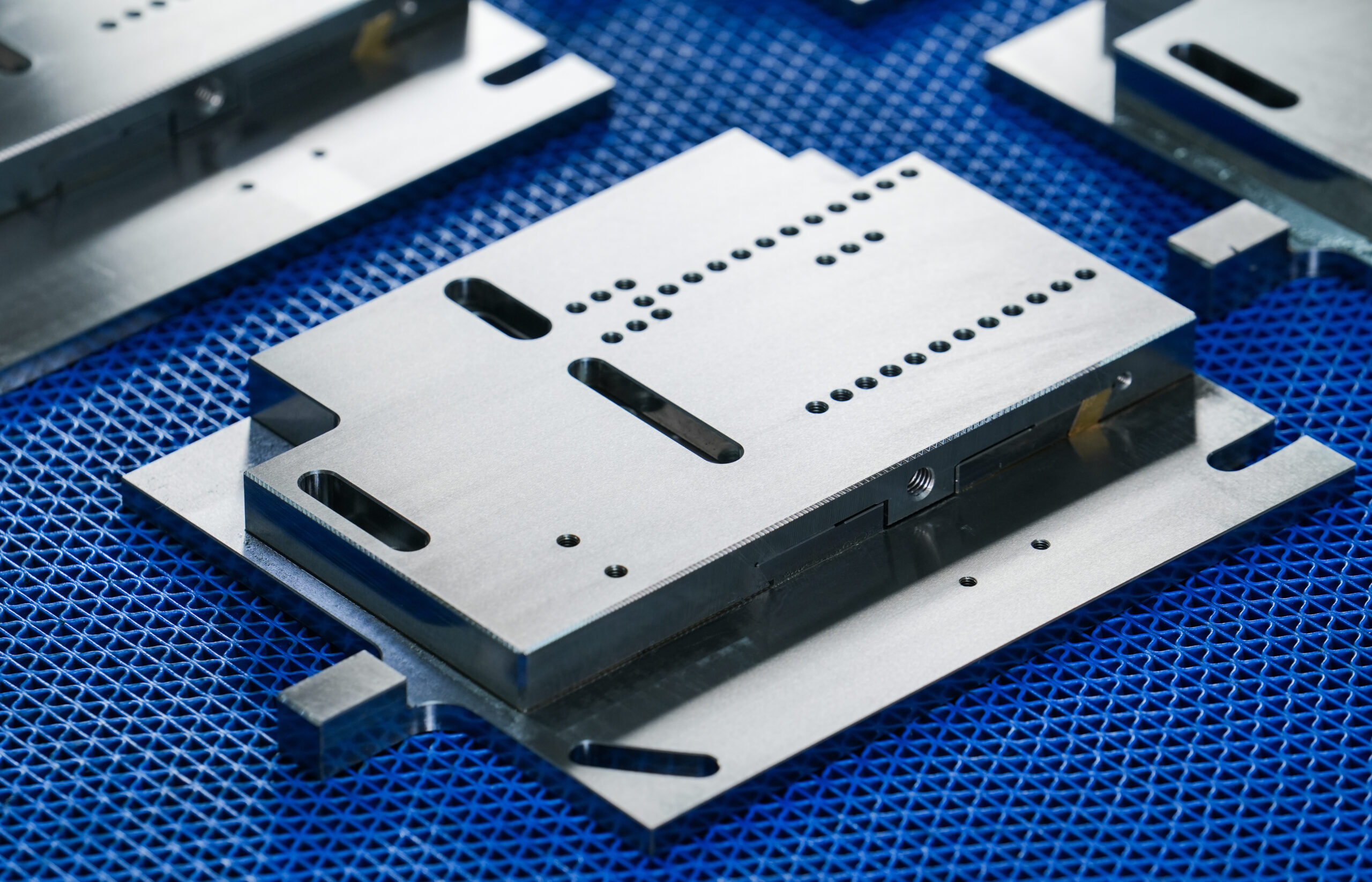

Our laser tube cutting delivers precise results, creating clean edges and intricate forms for round, square, and custom-shaped tubing. Perfect for complex assemblies, our high-speed process enhances accuracy, saves production time, and ensures every cut meets your exact specifications for quality, consistency, and performance.

Laser tube cutting employs high-precision laser technology to cleanly cut, slot, and form metal tubes and pipes with exceptional accuracy, enabling intricate designs and smooth finishes. This method enables the creation of intricate designs and smooth finishes, making it ideal for structural parts, automotive frames, and specialized fabrication projects.

| パラメータ | 仕様 |

|---|---|

| 寸法公差 | ±0.1 mm to ±0.3 mm |

| Kerf Width | 0.1 mm to 0.3 mm |

| Minimum Feature Size | 0.2 mm (material-dependent) |

| Material Thickness Range | 0.1 mm to 25 mm |

| Edge Quality | Smooth, minimal burring |

| Flatness After Cutting | ≤ 0.5 mm per 1000 mm |

We offer laser tube cutting services that ensure fast, precise results for round, square, and rectangular tubing. This technology produces intricate hole patterns, miters, and cutouts in a single step, eliminating extra processing. Capable of working with various materials and diameters, it’s perfect for frames, furniture, and structural parts requiring strength and uniformity.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

6061 (Extruded or Drawn)

304, 316 (Welded or Seamless)

Steel A513 Type 1, HREW

Steel A513 Type 2, CREW

Steel A513 Type 5, DOM

Steel 4130 (Chromoly), Seamless

Steel A513 (Rectangular)

Steel 4130 (Chromoly)

Cold Drawn Seamless (Rectangular)

Yicen Precision offers a variety of finishing services to ensure your parts meet exacting standards.

The default finish from laser cutting may show minor discoloration or edge roughness due to heat exposure, suitable for internal or non-cosmetic features.

Fine glass beads are blasted onto the surface to create a uniform matte or satin finish, ideal for cosmetic consistency.

Applies a durable, protective coating that improves corrosion resistance and allows for various color options. Perfect for functional and aesthetic applications.

Rotating abrasive belts or brushes create a fine linear grain, removing oxidation and delivering a clean, satin-like appearance.

Employs laser energy to melt and smooth the surface, significantly reducing roughness and enhancing surface clarity

Electrochemically forms a protective oxide layer on aluminum parts, boosting corrosion resistance and allowing for vibrant color finishes

Removes sharp edges and burrs using mechanical or chemical processes, improving safety and surface smoothness.

An acid or electrochemical treatment applied to stainless steel to remove free iron and improve corrosion resistance, enhancing long-term durability.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

In laser tube cutting, a high-intensity beam generated by fiber or CO₂ sources, is directed to slice through tubes of various shapes, including round, square, and custom profiles. The process is highly automated, driven by CAD/CAM software, which ensures each cut follows exact specifications.

The process begins with a digital design file, typically in DXF or STEP format. The file is loaded into CNC software, which converts the design into exact cutting commands. Engineers can include complex hole patterns, miters, or engraving directly into the plan.

Tubes are placed into an automated loading system that aligns and secures them. Advanced machines can handle diameters ranging from 12 mm to over 200 mm, accommodating various industrial applications.

A high-powered laser, often exceeding 3,000 watts, focuses its beam onto the material surface, melting or vaporizing the metal instantly. Assist gases such as nitrogen or oxygen help remove molten material and prevent oxidation, ensuring a clean, burr-free edge.

One of the biggest advantages is the ability to cut complex geometries such as slots, angled cuts, and intricate patterns in a single operation, eliminating the need for secondary machining.

After cutting, each tube is inspected for dimensional accuracy and surface finish. Automated measurement systems can achieve tolerances as tight as ±0.1 mm, making the process ideal for industries like aerospace, automotive, and medical manufacturing.

Laser tube cutting is a powerful manufacturing method, it comes with its own set of challenges that must be managed to ensure consistent results.

Metals such as copper, brass, and some aluminum alloys can reflect the laser beam back toward the cutting head, potentially damaging optics. Using fiber lasers, specialized coatings, or surface treatments can help minimize reflectivity and improve cutting performance.

During cutting, thin-walled tubes can easily deform due to heat exposure. Excessive thermal input can cause deformation, affecting accuracy and fit. Adjusting power levels, cutting speeds, and assisting gas flow is essential to maintain dimensional stability.

Intricate geometries require precise CNC programming to ensure clean, accurate cuts. Poorly optimized cutting paths can waste material, increase cycle times, and result in part misalignment. Skilled programming ensures efficiency and quality.

Laser tube cutting machines rely on clean optics, properly aligned nozzles, and reliable gas delivery. Neglecting maintenance can lead to reduced cut quality, costly downtime, and shortened equipment lifespan.

Most laser tube cutting systems handle wall thicknesses up to 10–12 mm efficiently. Cutting thicker materials can slow production and may require multiple passes, increasing both cycle time and operating costs.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Do you offer post-cutting finishing?

Yes, we can provide deburring, cleaning, and secondary machining if required.

Is there any distortion to the tube?

No, laser cutting is non-contact and does not deform the material.

Can you cut holes and slots in tubes?

Absolutely, we can cut precise holes, slots, bevels, and custom shapes.

Is laser tube cutting suitable for large production runs?

Yes, it’s highly efficient for both small and high-volume batches.

What types of tubes can you cut?

We cut round, square, rectangular, and custom-profile metal tubes.