Typically ±0.001 mm or tighter depending on part requirements.

Achieve exceptionally tight tolerances and flawless finishes for critical components. Our precision grinding services deliver high accuracy, ensuring the most demanding parts meet the highest standards. With advanced machinery and expert craftsmanship, we guarantee smooth surfaces and superior performance for every project, from prototyping to full-scale production.

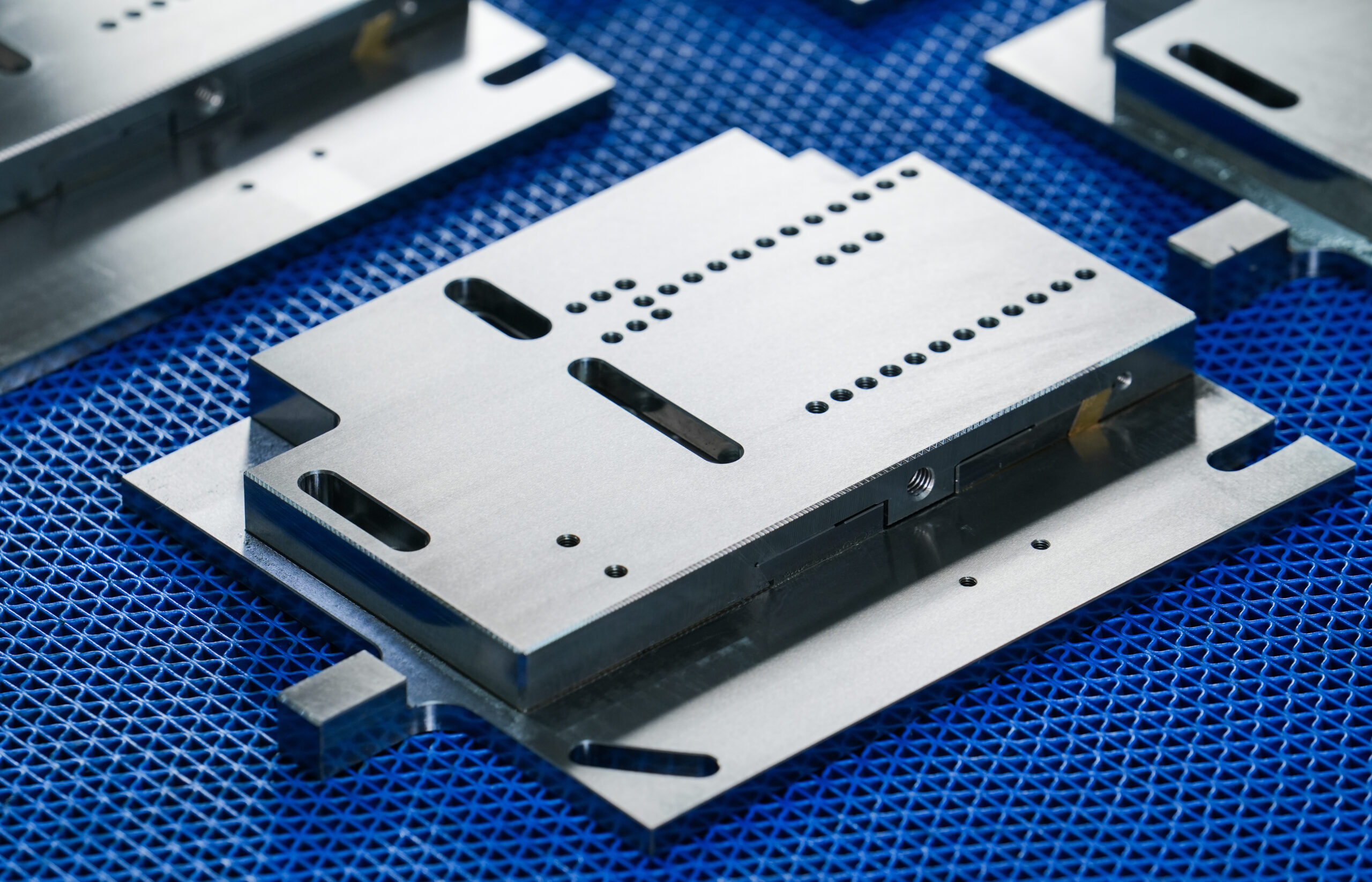

Precision grinding is a high-accuracy machining technique used to achieve extremely tight tolerances and smooth finishes on metal components. Our precision grinding services are designed for critical parts that demand precise dimensions, superior finishes, and consistent quality such as shafts, bearing surfaces, and tooling components. Whether handling small or large-volume projects, we use advanced equipment to ensure reliable, repeatable results for every part.

| Grinding Type | Typical Tolerance Range (mm) | Surface Finish (Ra, µm) | Application Examples |

|---|---|---|---|

| 平面研磨 | ±0.002 to ±0.01 | 0.1 – 0.8 | Die plates, flat tooling components, fixture bases |

| Cylindrical Grinding (OD/ID) | ±0.001 to ±0.005 | 0.2 – 0.6 | Shafts, bushings, hydraulic spools |

| Centerless Grinding | ±0.001 to ±0.005 | 0.1 – 0.4 | High-volume pins, rods, tubes |

| Form Grinding | ±0.002 to ±0.01 | 0.2 – 0.6 | Gear profiles, punch dies, custom contours |

| Jig Grinding | ±0.001 to ±0.003 | 0.1 – 0.3 | Precision holes, mold cavities, aerospace parts |

| Flat Lapping / Honing | ±0.0005 to ±0.003 | 0.05 – 0.2 | Optical components, sealing surfaces |

We provide precision grinding services for components requiring precise dimensions and exceptional surface quality. Using state-of-the-art grinding machines, we achieve micron-level tolerances on various metals. This service is perfect for creating molds, dies, and components used in industries such as aerospace, healthcare, and manufacturing. Every grind ensures consistency, repeatability, and flawless surface finishes.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

スチール

鋳鉄

工具鋼

アルミニウム

真鍮

Copper

Carbide

Ceramics

Austenitic Stainless Steel

Martensitic Stainless Steel

Inconel

Hastelloy

Monel

PEEK

PTFE

UHMW

ナイロン

At Yicen Precision, precision grinding delivers exceptionally flat, smooth surfaces with tight dimensional tolerances, ideal for components requiring high accuracy and superior finish quality.

Produces fine surface textures with minimal roughness, enhancing both appearance and functional performance.

Effective on a wide range of metals and alloys, including hardened steels, stainless steel, and tool steels.

Can be combined with polishing or lapping for even finer finishes and enhanced surface integrity.

Delivers superior control over flatness and parallelism, making it ideal for parts that demand precise geometric tolerances.

Ensures repeatable, high-precision results across multiple parts, critical for production runs and tight-tolerance components.

Optional deburring services can remove sharp edges left by grinding, improving handling safety and preparing parts for assembly.

With advanced grinding techniques, near-mirror finishes can be achieved for components requiring exceptional visual clarity and ultra-low surface roughness.

Creates an ideal base surface for subsequent finishes like plating, anodizing, or coating, ensuring better adhesion and uniformity in later processes.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

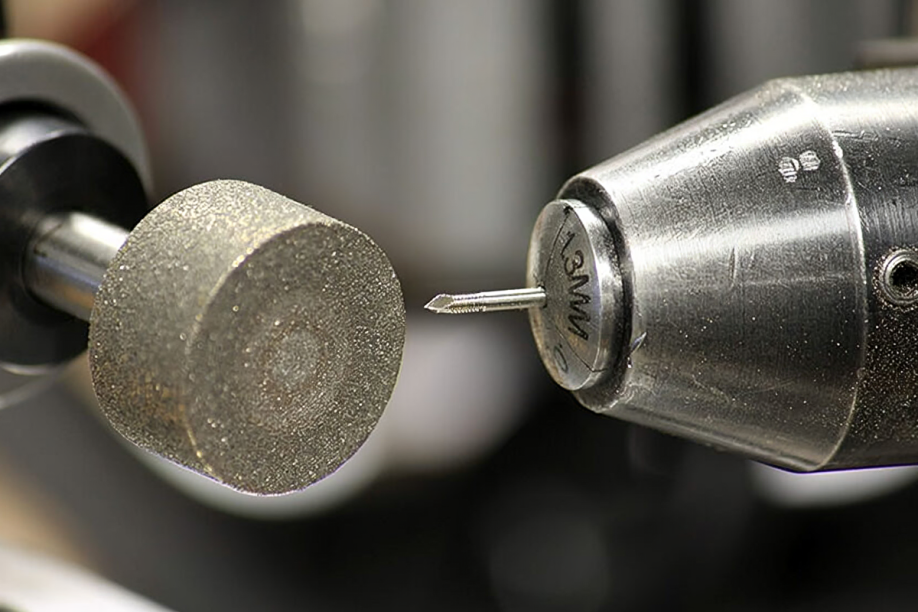

The precision grinding process involves the use of an abrasive wheel to remove small amounts of material from a workpiece to achieve extremely tight tolerances and smooth finishes. Here’s an overview of the key steps involved:

A suitable grinding wheel is chosen based on the material of the workpiece and the finish required. As the grinding wheel spins, the abrasive particles slowly wear away material from the workpiece surface.

The workpiece is carefully positioned on the grinding machine, and the grinding wheel is aligned to the desired grinding angle and speed. CNC machines are commonly employed to guarantee accuracy and consistent results in every operation.

The grinding wheel makes contact with the workpiece, rotating at high speeds to gradually remove small amounts of material. This process smooths and shapes the surface, repeating until the required dimensions and finish are met.

Friction between the grinding wheel and the workpiece can cause heat buildup during the grinding process. Coolant or lubrication is applied to reduce heat and prevent damage to the part.

Depending on the application, the workpiece may undergo additional steps like polishing, deburring, or coating to enhance surface quality and performance.

Precision grinding provides exceptional accuracy, smooth finishes, and reliable results, making it ideal for producing high-quality components across a variety of industries.

Precision grinding allows manufacturers to achieve extremely tight tolerances, often within ±0.01 mm or better, which is essential for parts that require exact measurements and high functionality. This level of precision is crucial in industries like aerospace, medical devices, and automotive components.

Precision grinding produces an exceptionally smooth surface, often required for parts that need both aesthetic appeal and functional performance. This surface quality reduces friction, improving the longevity and reliability of components.

Traditional machining methods may struggle with intricate or detailed shapes, precision grinding excels in producing complex geometries with high accuracy. This efficiency is beneficial for intricate designs or tight spaces within components.

Precision grinding ensures that each part produced is consistent and identical, even in high-volume production. CNC-controlled grinding machines allow manufacturers to consistently produce high-quality results across large production runs

Whether for prototype development or full-scale production, precision grinding is used across industries such as aerospace, automotive, medical devices, and tooling, making it a versatile and reliable process for various applications.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

What tolerance levels can you achieve with precision grinding?

Typically ±0.001 mm or tighter depending on part requirements.

Which materials are suitable for your grinding services?

We grind steels, stainless steel, titanium, carbide, and more.

Do you offer both manual and CNC precision grinding?

Yes, we provide both depending on the complexity and volume.

Can you grind internal surfaces?

Yes, we offer internal cylindrical grinding for precision bores.

Do you provide inspection reports?

Yes, we offer detailed quality documentation with CMM and surface finish data.