We offer plastics, resins, aluminum, stainless steel, and engineering-grade composites.

Accelerate your product development with accurate, high-quality prototypes crafted from a wide range of materials. Our rapid prototyping services ensure fast turnaround times and accurate results, enabling you to test and refine designs quickly, making the process more efficient and cost-effective.

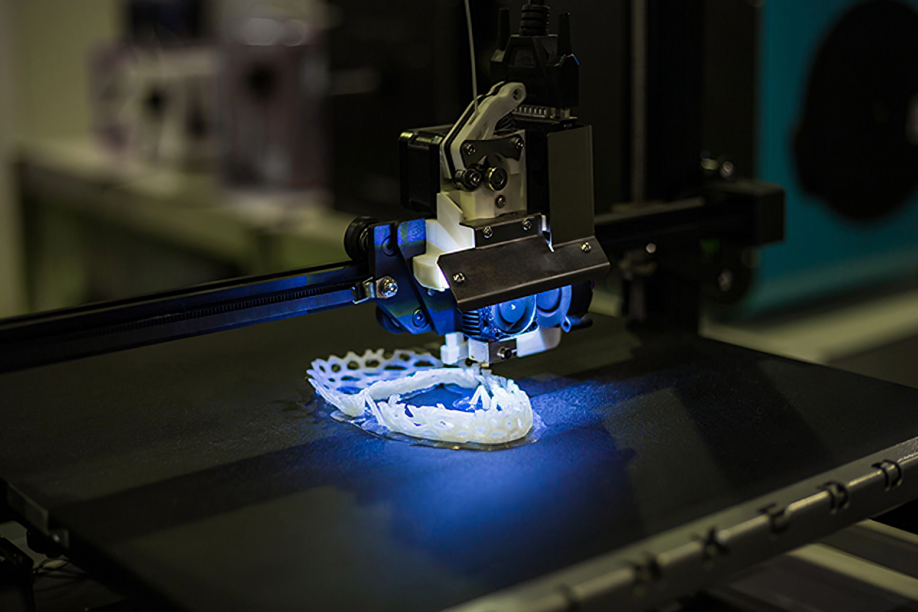

Rapid prototyping is an efficient, cost-effective method for creating physical models directly from 3D CAD designs, allowing for quick validation of form, fit, and function. We provide a variety of rapid prototyping technologies, including CNC machining, FDM, SLA, SLS, and MJF, to create high-quality prototypes in both plastic and metal. Whether you require visual models, functional components, or engineering validation, our rapid prototyping services streamline product development, minimize risk, and bring your concepts to life faster.

| パラメータ | 仕様 |

|---|---|

| 寸法公差 | ±0.1 mm to ±0.5 mm |

| 表面仕上げ (Ra) | 3.0 – 25.0 µm (depends on process & material) |

| Wall Thickness (Min) | 0.5 mm (plastic), 1.0 mm (metal) |

| Feature Resolution | ~0.2 mm (FDM), ~0.05 mm (SLA/SLS/CNC) |

| Build Size Capacity | Up to 500 x 500 x 500 mm (varies by process) |

| Layer Thickness (3D Print) | 0.05 – 0.3 mm |

Our rapid prototyping services help turn your concepts into tangible parts efficiently and with speed. By combining CNC machining, 3D printing, and other fast-turn technologies, we deliver highly functional prototypes with precision and speed. Our services support iterative design, testing, and refinement across a wide range of industries, allowing you to receive production-quality prototypes in just days, not weeks.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

PLA

ABS

PETG

Nylon (PA12, PA11)

Polycarbonate (PC)

PEEK

PMMA

Resins (SLA/DLP)

Aluminum (6061, 7075)

Stainless Steel (304, 316, 17-4 PH)

Titanium (Ti6Al4V)

真鍮

Copper

Carbon Fiber Reinforced Plastics (CFRP)

Fiberglass Composites

Glass-Filled Nylon (PA-GF)

Carbon Fiber Composites

ファイバーグラス

Glass-filled Nylon

TPU

TPE

Silicone

Rubber-like Resins (SLA/DLP)

At Yicen Precision, our Rapid prototyping services ensure your parts achieve precise flatness, superior surface quality, and the ideal finish for both prototyping and production needs.

Parts are delivered in their original state post-printing or machining.

Improves surface smoothness and visual quality. Can range from matte to mirror finishes depending on the application.

Adds custom color or protective layers for presentation models or market-ready prototypes.

Uses controlled chemical vapors to reduce surface roughness and smooth layer lines, creating a semi-gloss, sealed finish for plastic prototypes.

Applies fine media to create a uniform matte or satin finish, improving aesthetics and hiding minor imperfections on both plastic and metal prototypes.

Deposits a thin layer of metal onto the part’s surface, enhancing appearance, strength, and conductivity ideal for functional and cosmetic prototypes.

Adds color to plastic prototypes through immersion dyeing, providing vibrant, uniform shades without affecting dimensional accuracy.

Includes precision fitting, gluing, and additional touch-ups to refine prototype appearance and functionality, ensuring parts are ready for testing or presentation.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

Rapid prototyping is a critical step in modern product development, offering a fast, cost-effective way to bring your ideas to life. Here’s an overview of the process:

The first step in rapid prototyping is conceptualizing the product and creating a detailed design. This design is typically created using 3D CAD (Computer-Aided Design) software, which allows for precise modeling of the part. The digital model serves as the foundation for creating the prototype and is crucial in determining the part’s geometry, dimensions, and functionality.

After finalizing the design, selecting the right material is essential for ensuring the prototype’s functionality and performance. Materials can range from plastics, metals, and composites to rubber and ceramics, depending on the specific requirements of the project.

Once the design and materials are selected, the next step is building the prototype. Rapid prototyping allows for the creation of parts in hours or days rather than weeks, as would be the case with traditional manufacturing methods. The chosen technology determines how the material is built up or shaped to match the digital model.

After the prototype is created, it undergoes a series of tests to evaluate its functionality, fit, and performance. This step allows engineers and designers to assess whether any adjustments are needed. Rapid prototyping makes it easier to modify the design and quickly create an updated version of the prototype, facilitating faster improvements.

Once the prototype has been refined and the design validated, it can move into the production stage. Some rapid prototyping methods, such as SLA (Stereolithography) or SLS (Selective Laser Sintering), can also be used for low-volume production.

Rapid prototyping relies on several advanced technologies that enable the fast and precise creation of prototypes. Each technology has its advantages, depending on the part’s design, material requirements, and desired finish.

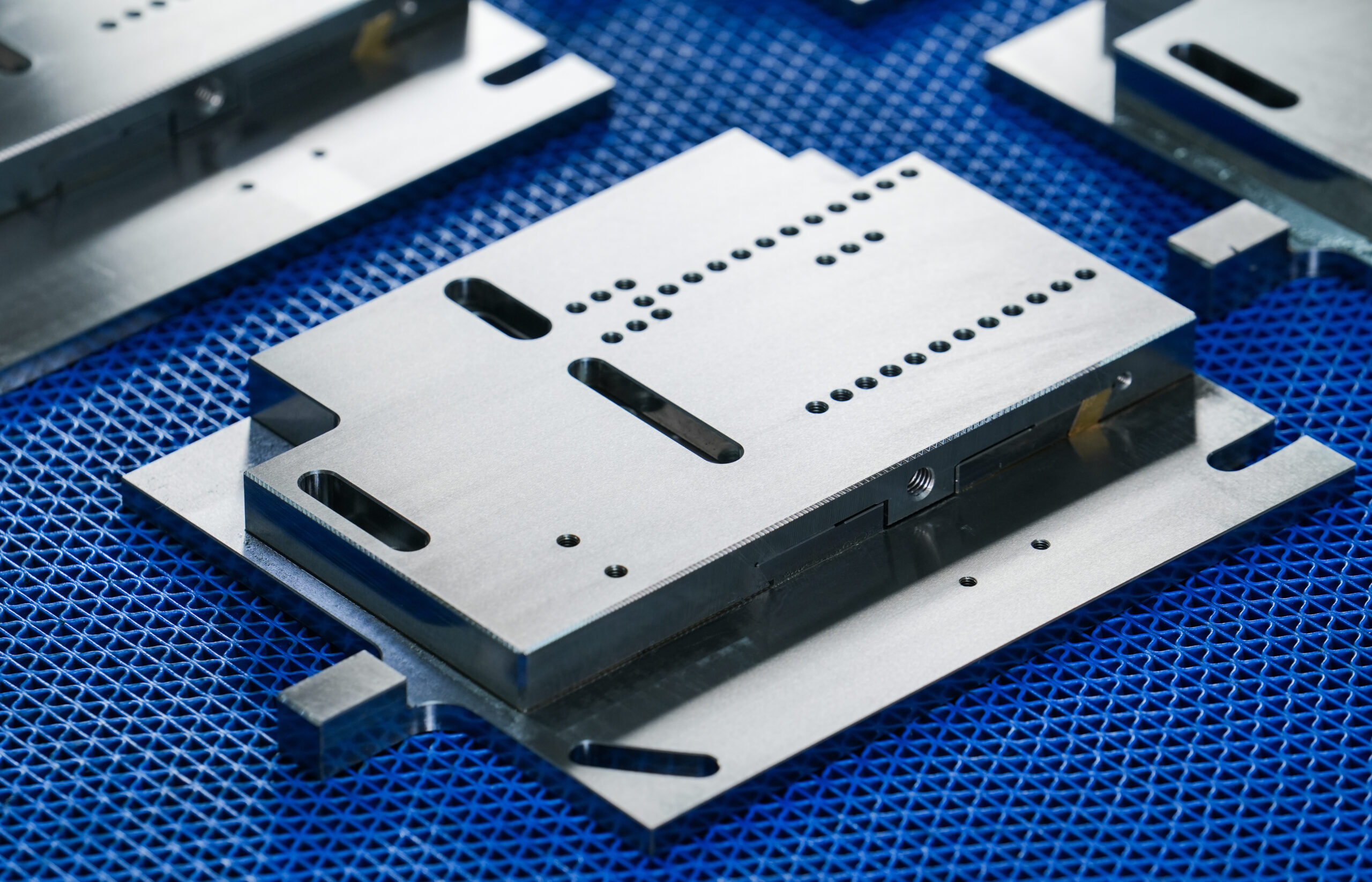

CNC (Computer Numerical Control) machining is one of the oldest yet most reliable technologies used in rapid prototyping. CNC machining offers high precision and is ideal for creating functional parts from metals or plastics.

FDM is a popular 3D printing technology used for rapid prototyping. This process involves extruding a thermoplastic material in layers to build up the prototype. FDM is widely used for creating durable prototypes and is particularly suited for plastic parts.

SLA is a 3D printing technology that uses a laser to cure liquid resin into solid layers. SLA is known for producing highly detailed prototypes with smooth surface finishes. It’s ideal for parts that require high accuracy and fine details, often achieving tolerances of ±0.1 mm. SLA is commonly used for visual prototypes or components that require intricate features.

SLS is a 3D printing technique that employs a laser to fuse powdered material into a solid object. Unlike SLA, SLS uses powdered metals, plastics, or ceramics, making it ideal for functional prototypes or small production runs. SLS is highly effective in producing parts with complex geometries and high strength, often used for end-use applications in industries like aerospace and automotive.

MJF is a more advanced 3D printing technology that uses a combination of inkjet printing and infrared heat to fuse layers of powder into solid parts. MJF offers high strength and detailed resolution and is faster than SLS. This technology can create functional parts with high accuracy and is ideal for rapid prototyping as well as low-volume production.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

What materials are available for rapid prototyping?

We offer plastics, resins, aluminum, stainless steel, and engineering-grade composites.

How quickly can I receive my prototype?

Typical turnaround is 2 to 7 business days depending on complexity.

Can I get functional prototypes for mechanical testing?

Yes, CNC machining and select 3D printing methods provide functional prototypes.

Do you help optimize designs for prototyping?

Absolutely, our engineers provide design feedback to enhance manufacturability.

Is there a minimum order quantity for prototyping?

No, we accommodate single prototypes up to small production runs.

Can rapid prototyping match final production quality?

Prototypes closely mimic final parts but may differ slightly in finish or material properties.

Do you offer assembly services for prototype components?

Yes, we provide assembly and testing support to deliver ready-to-use prototypes.