We use nylon (PA12), glass-filled nylon, and other engineering-grade powders.

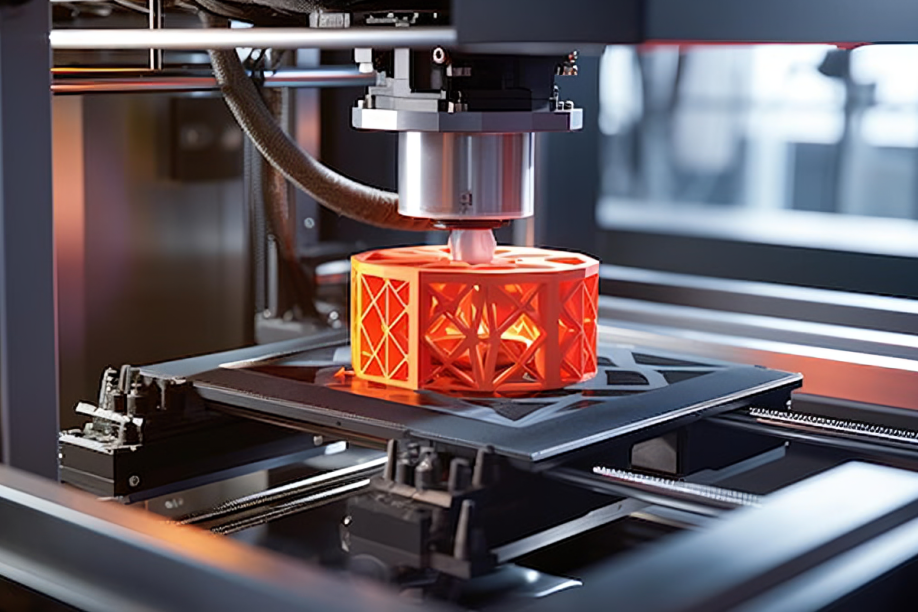

Selective Laser Sintering (SLS) is a cutting-edge 3D printing method that utilizes a high-powered laser to fuse powdered thermoplastics, such as nylon, layer by layer. This technology creates robust, long-lasting parts without requiring support structures, making it perfect for detailed designs and complex shapes. SLS is well-suited for rapid prototyping and small-scale production, offering outstanding mechanical properties, heat resistance, and design flexibility.

Our SLS 3D printing service produces durable, high-performance plastic parts without the requirement for support structures. By using a laser to fuse nylon powders layer by layer, SLS allows for the creation of complex, interlocking designs with exceptional mechanical strength. It’s perfect for functional testing, low-volume production, and end-use applications. We prioritize precision, reliability, and quick turnaround for even the most challenging projects.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

Durable plastic

PA12

PA 2200

Stiff plastic

PA12 GF

PA 3200 GF

Ductile plastic

PA11

Rilsan® Invent Natural

High-performance plastic

Carbon-filled PA12

PA 602-CF

Carbonmide

Metallic gray plastic

Aluminum-filled PA12

Alumide

Heat-resistant plastic

Mineral fiber-reinforced PA12

PA 620-MF

Meets FAR 25.853 60-second burn specification

PA 606-FR

We offer surface finishing solutions designed to enhance the appearance, durability, and performance of your SLS parts.

Uses abrasive media in a vibrating tumbler to smooth surfaces and reduce roughness. Ideal for improving the feel and appearance of SLS parts while maintaining part geometry.

A cost-effective method for adding color by immersing SLS parts in dye solutions. Provides vibrant, uniform coloring without adding thickness or affecting details.

Applies controlled chemical vapors to melt outer surfaces slightly, reducing porosity and achieving a smoother, semi-gloss finish on SLS parts.

Impregnates SLS parts with resins or waxes to strengthen the surface, reduce porosity, and improve impact resistance for functional prototypes or end-use components.

Primer layers are applied to fill minor imperfections before painting, ensuring smooth color application and improved visual consistency on finished parts.

Add surface textures to enhance grip, achieve a specific design effect, or mask layer lines. Great for ergonomic parts and components requiring tactile functionality.

Custom paints and protective coatings can be applied to add color, increase surface durability, or provide environmental protection

手動または機械によるサンディングで表面を滑らかにし、ポリッシングできれいで光沢のある仕上げを実現します。プレゼンテーションモデル、ビジュアルプロトタイプ、最終用途部品に最適です。

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

Selective Laser Sintering (SLS) is an advanced 3D printing technique that has transformed the manufacturing industry. It utilizes a high-powered laser to fuse powdered materials layer by layer, forming solid parts. Behind this cutting-edge technology, several advanced techniques are employed to ensure precision and functionality.

The core of the SLS process is the laser itself. A high-powered laser, typically CO2, precisely scans the surface of the powder bed, fusing particles together according to the digital design. This ensures that parts are created with a high degree of accuracy, and the final product exhibits outstanding strength and durability.

A thin layer of powder is uniformly spread over the print bed, and the laser fuses the powder in precise patterns to create a solid layer. The powder bed helps in supporting the structure during the printing process, which eliminates the need for additional support structures commonly required in other 3D printing methods like SLA (Stereolithography) or FDM (Fused Deposition Modeling).

SLS can work with a wide range of materials, but the most common ones are thermoplastics such as Nylon, Polyamide, and their various composites. These materials are known for their excellent mechanical properties, including toughness, heat resistance, and chemical stability. Materials like Glass-filled Nylon or Carbon Fiber composites can be used for enhanced strength and rigidity.

Powder recycling is another key aspect of the SLS process. Excess powder from previous prints can be reused, reducing waste and lowering material costs. Some advanced SLS machines incorporate powder sieving systems to ensure that the reused powder is of high quality, with minimal degradation from previous builds.

Despite its numerous advantages, SLS is not without its challenges. Manufacturers must overcome several hurdles to maximize the potential of SLS technology.

One of the most common challenges with SLS is the rough surface texture of the printed parts. While SLS parts are mechanically strong, they can often have a powdery, grainy surface, especially in areas where the laser has not completely sintered the material. To improve aesthetics and functionality, parts often require post-processing treatments such as bead blasting, polishing, or coating.

SLS can print using a variety of materials, the selection is still more limited compared to other 3D printing technologies like FDM or SLA. In addition, the mechanical properties of SLS materials can vary depending on the material type, powder quality, and laser settings. For example, while materials like Nylon and Polyamide are commonly used, they may not be suitable for all applications, particularly those requiring extreme heat resistance or flexibility.

During the cooling stage of the SLS process, parts may undergo distortion or reduction in size. This is especially true when using materials with higher thermal expansion rates. Such distortions can affect the final dimensions and accuracy of the part, which can be problematic for applications requiring tight tolerances. Effective temperature control and careful design considerations are crucial to mitigating these issues.

SLS printers are typically expensive, making it difficult for smaller businesses to invest in the technology. Additionally, these machines require regular maintenance to ensure that the lasers and powder management systems function properly. This adds to the overall cost of using SLS for manufacturing and rapid prototyping.

SLS is slower compared to some other 3D printing techniques, particularly for large parts or multiple items. While SLS is excellent for producing highly detailed parts with complex geometries, the layer-by-layer process can take longer than methods that use different mechanisms for material deposition.

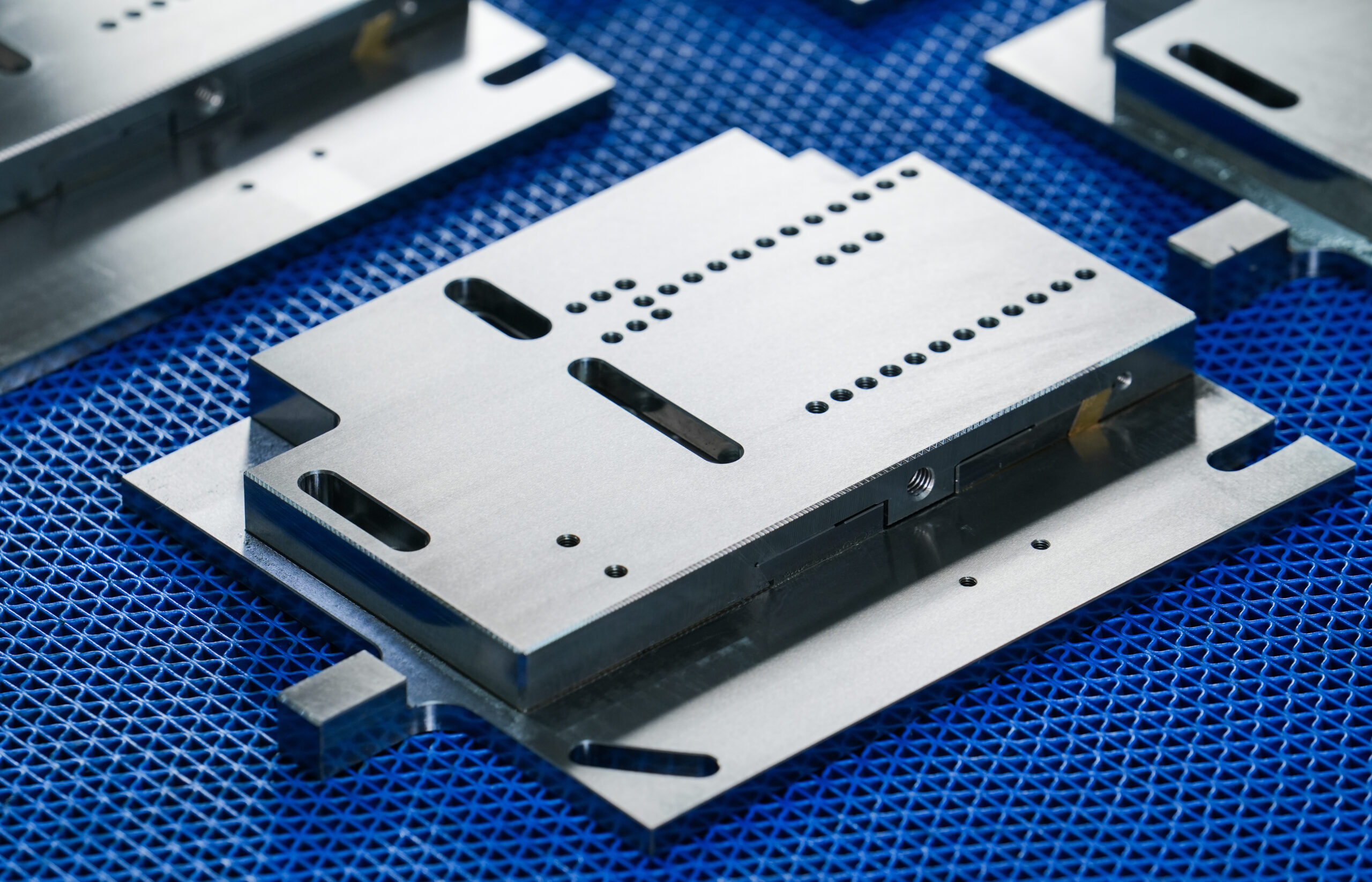

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

What materials do you use for SLS?

We use nylon (PA12), glass-filled nylon, and other engineering-grade powders.

Can SLS produce complex geometries?

Yes, SLS can create intricate designs including internal features and moving parts.

Are SLS parts strong enough for functional use?

Absolutely, SLS parts are durable and flexible for demanding applications.

What is the maximum build size?

We accommodate parts up to several hundred millimeters per side.

Is post-processing required?

Minimal cleaning and finishing are needed; additional services are available.

Can SLS produce multi-part assemblies?

Yes, SLS can print interlocking and assembled parts in one build.