Yes, including polishing, coating, and additional fabrication if needed.

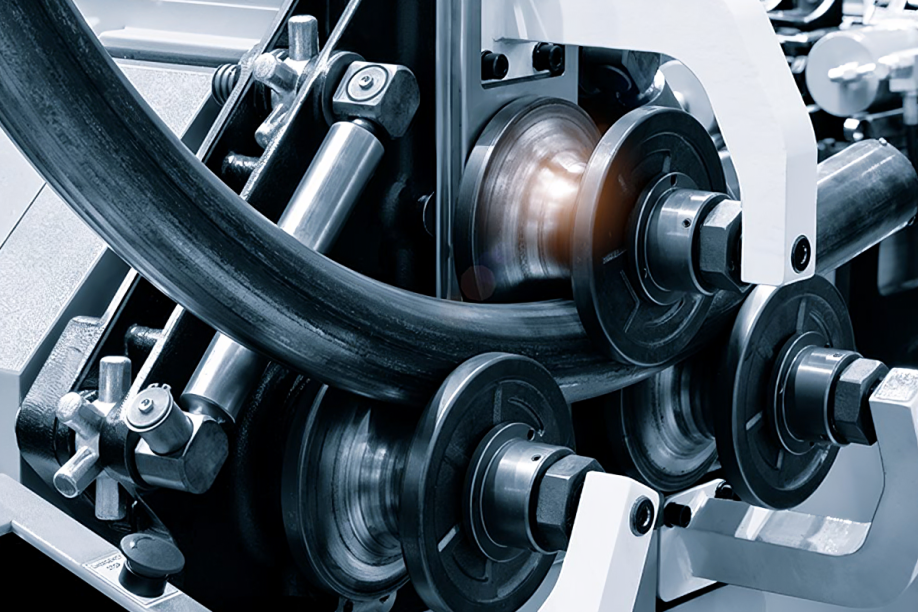

Customised tube bending solutions deliver flawless curves and accurate angles for tubes of varying materials and diameters. Using advanced equipment and skilled craftsmanship, every bend matches precise design requirements perfect for functional, structural, or decorative needs while ensuring long-lasting strength, consistent accuracy, and a high-quality finish in every project.

Tube bending is a process used to permanently shape metal tubing into desired angles or curves without compromising strength or integrity. At Yicen Precision, we offer precision tube bending services for a variety of industries, delivering accurate bends for frames, handles, hydraulic lines, and more.

| パラメータ | 仕様 |

|---|---|

| 寸法公差 | ±0.5 mm to ±1.0 mm |

| Bend Angle Tolerance | ±0.5° to ±1.0° |

| Ovality (Out-of-Roundness) | ≤ 10% of tube diameter |

| Wall Thickness Variation | ±10% (depends on bend radius & tube spec) |

| Centerline Radius Tolerance | ±0.5 mm to ±1.0 mm |

| Minimum Bend Radius | ≥ 1.5× tube OD (material-dependent) |

Precision tube bending services create metal tubes with exact angles and smooth curves while preserving their structural strength. Suitable for various materials and diameters, our capabilities serve automotive, furniture, and industrial sectors. Advanced equipment delivers wrinkle-free bends and uniform geometry, maintaining quality and accuracy throughout every production run.

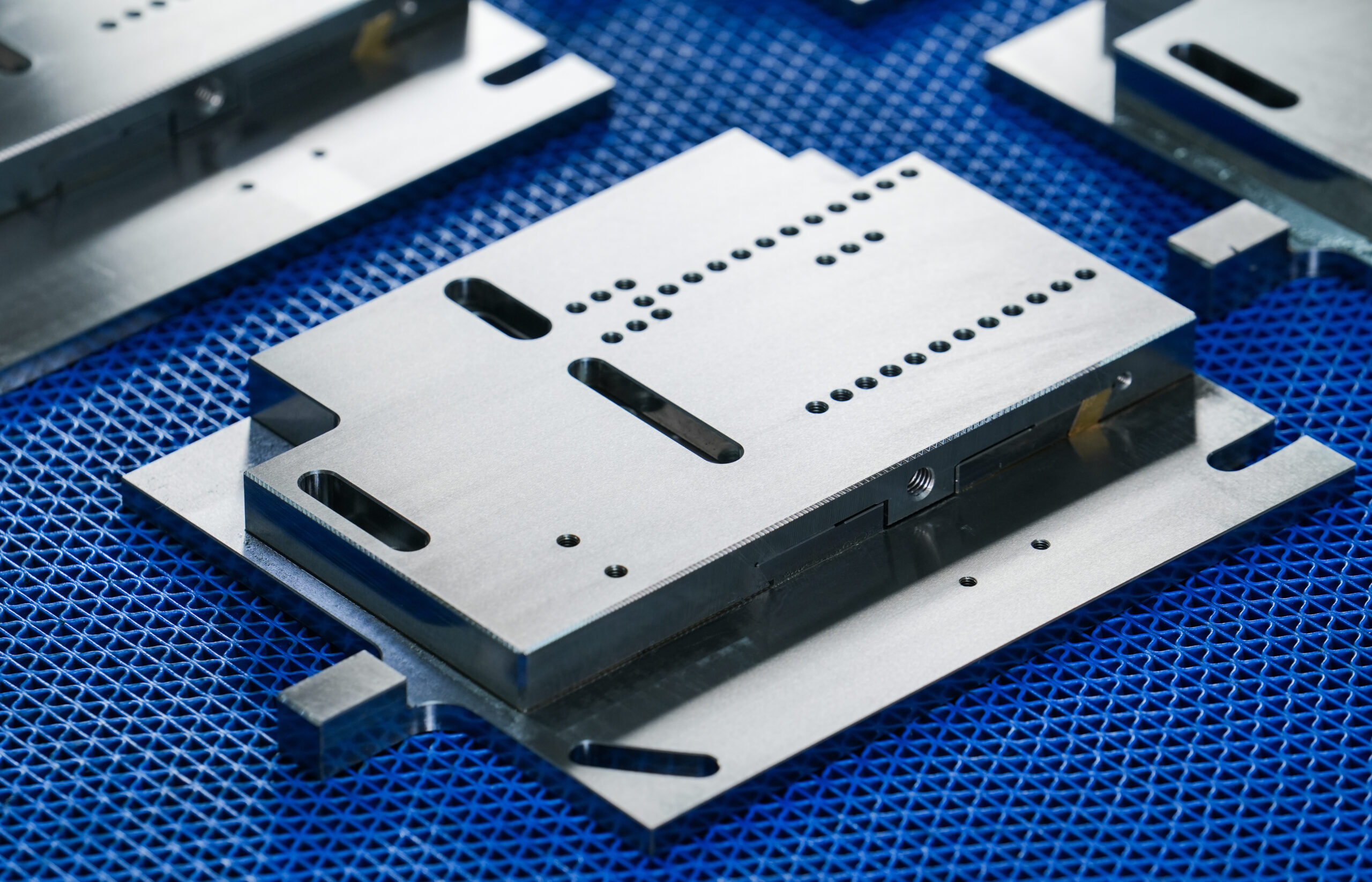

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

304, 316 (Welded or Seamless)

6061 (Extruded or Drawn)

4130 (Seamless)

A513 (Type 1 HREW, Type 2 CREW, Type 5 DOM)

Yicen Precision offers a variety of finishing options tailored to your project needs.

The default finish immediately following bending. Surfaces may exhibit minor marks, distortions, or discoloration due to forming stresses. Surface roughness may also be present.

Applies a consistent matte or satin finish by blasting the surface with fine media. This process helps remove oxidation and create a clean, uniform appearance.

Applies a durable, protective layer available in various colors and textures, offering excellent corrosion resistance and a finished, aesthetic appearance.

Used to smooth uneven areas or surface imperfections that may result from the bending process, especially on tight radii.

Delivers a smooth, reflective surface ideal for applications where aesthetics and low surface friction are important.

In specific applications, post-bend heat treatment may be applied to relieve internal stresses and improve dimensional stability

Creates a protective oxide layer that enhances corrosion resistance and allows for decorative coloring, ideal for lightweight, corrosion-resistant aluminum tubes.

Recommended for stainless steel tubes. This chemical treatment removes surface contaminants, enhances corrosion resistance, and restores the protective oxide layer.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

A blend of advanced machinery and precise techniques allows us to deliver flawless, repeatable bends across various materials, diameters, and designs ensuring accuracy, durability, and efficiency for every project

Our CNC tube bending machines deliver unmatched precision, achieving accuracy within ±0.1mm. Computer-controlled programming ensures every bend is consistent, even in high-volume runs. This technology allows us to handle complex shapes and repeat them flawlessly, making it ideal for industries requiring tight tolerances and reliable quality.

In mandrel bending, a support rod is inserted into the tube during bending to keep its shape intact and avoid deformation. This technique is particularly effective for thin-walled or small-radius bends, ensuring the inside surface remains smooth and free from defects. It’s the go-to choice for hydraulic lines, exhaust systems, and other applications where internal flow efficiency is crucial.

Rotary draw bending combines precision tooling with controlled pressure to produce accurate and repeatable bends. This method excels in creating complex geometries and custom angles while preserving material strength. It’s widely used for decorative, structural, and performance-critical components where both aesthetics and durability matter.

Some projects require more than one bend radius in a single tube, and our multi-radius bending capabilities make that possible. By switching tools within the same setup, we produce components with varying curves without additional welding or assembly. This not only saves production time but also improves overall strength and finish.

Different metals react differently to bending forces, which is why we use material-specific settings for each project. Whether working with stainless steel, aluminum, copper, or specialty alloys, our adaptive technology adjusts pressure, speed, and tooling for optimal results.

Tube bending is about unlocking design possibilities, improving performance, and optimizing manufacturing efficiency. Here are some of the key benefits that make it an essential process for modern industries:

Tube bending enables smooth, continuous curves that can replace multiple welded joints. This not only creates a cleaner aesthetic but also opens up innovative design options that would be difficult or impossible to achieve with traditional fabrication methods.

Every joint or weld in a structure is a potential weak point. By bending a single continuous piece of tubing, the overall strength is maintained, reducing the risk of leaks, cracks, or structural failure. For example, in automotive roll cages, seamless bends can improve durability by up to 20% compared to welded sections.

Minimizing welds and fittings helps cut labor expenses while also reducing the amount of material wasted during production. In high-volume production, this can translate to 15–25% cost savings, making tube bending a more economical choice for manufacturers.

In applications such as fluid transfer systems or exhaust pipes, smooth bends reduce turbulence and pressure drops. This can improve efficiency and performance, whether you’re talking about a hydraulic system or an air intake manifold.

With CNC-controlled bending, each part is identical to the last, ensuring consistent quality across production runs. This is especially valuable in industries where tight tolerances and uniformity are critical, such as aerospace and medical equipment manufacturing.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Do you provide finishing services?

Yes, including polishing, coating, and additional fabrication if needed.

Is there a minimum order quantity?

We handle both prototypes and production volumes with flexible order sizes.

Do you offer custom or multi-axis bends?

Yes, we specialize in complex geometries and multi-plane bending.

Can you handle tight-radius bends?

Yes, we use mandrel bending to achieve tight-radius bends without distortion.

What tube sizes can you bend?

We bend tubes from small diameters up to several inches, depending on material.