Yes, we handle both custom prototypes and bulk production runs.

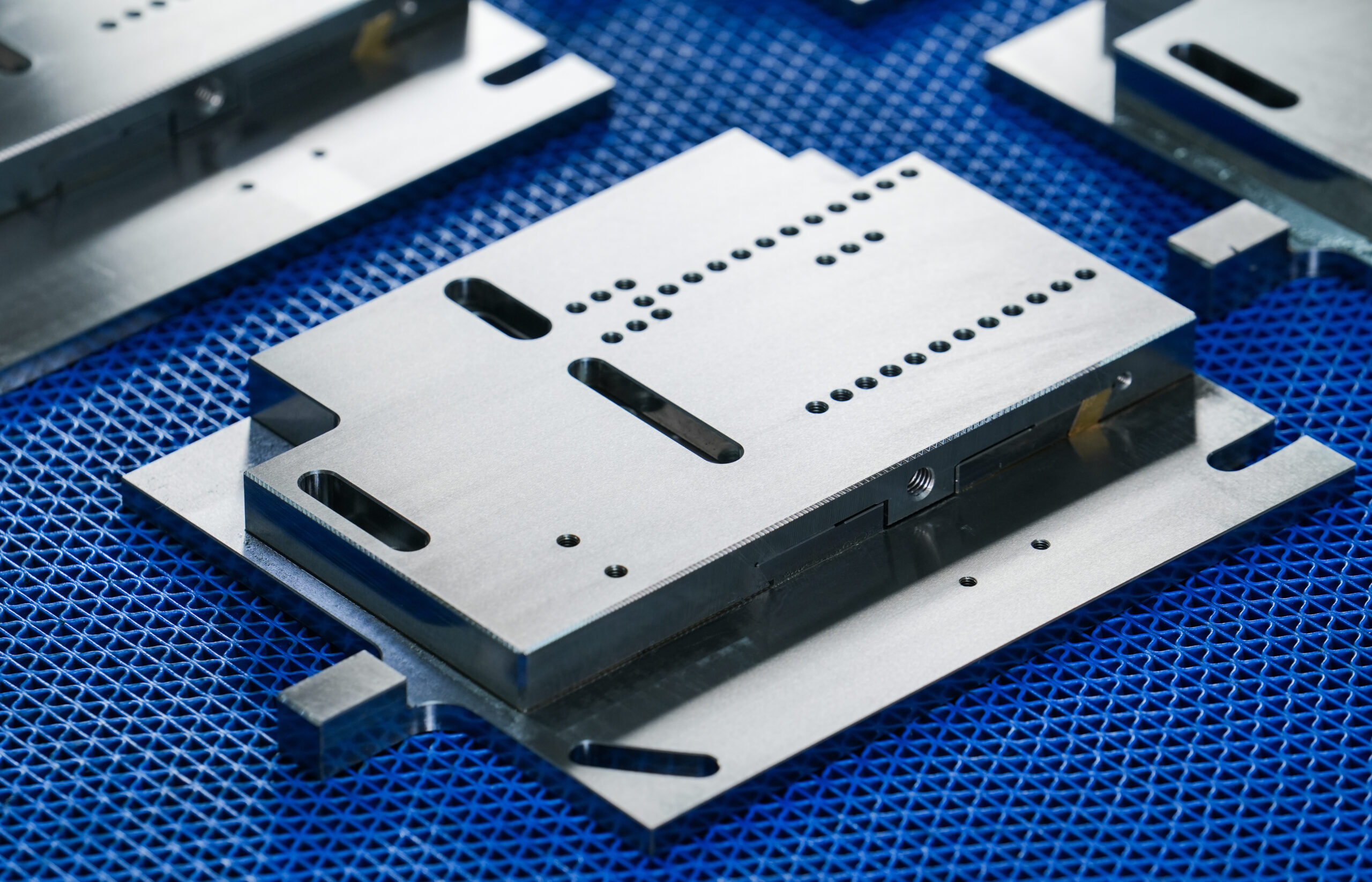

Waterjet cutting delivers precise, cold-cut results on almost any material, from metals to composites, without creating heat-affected zones. Ideal for intricate shapes and clean edges, this versatile process ensures accuracy, preserves material integrity, and supports both industrial projects and custom manufacturing needs.

Waterjet cutting harnesses a powerful stream of water, often blended with fine abrasives, to slice through diverse materials with exceptional precision without causing heat distortion. This process produces smooth, accurate edges, making it ideal for metals, composites, stone, and materials that are sensitive to heat.

| パラメータ | 仕様 |

|---|---|

| 寸法公差 | ±0.13 mm to ±0.25 mm |

| Minimum Feature Size | 0.8 mm to 1.0 mm |

| Material Thickness Range | 1 mm up to 150 mm |

| Edge Quality | Smooth, minimal heat-affected zone |

| Kerf Width | 0.8 mm to 1.3 mm |

| Straightness | ≤ 0.5 mm per 1000 mm |

High-pressure water, with or without abrasives, powers our waterjet cutting to handle metals, composites, glass, and stone without heat damage. Perfect for thick or delicate materials, it delivers precise, burr-free results while preserving integrity. Ideal for custom components, architectural elements, and demanding industrial applications.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

Titanium Grade 2 and 5

Nickel Alloy

ABS

Acetal (POM, Delrin)

PETG

PC

PP

PTFE

PVC

UHMW

Clear and Colored Acrylic (Plexiglass)

EVA Foam

Polyurethane Foam (PU)

Silicone Foam

Buna-N Rubber Blends

EPDM

Silicone Rubber

Paper Fiber

Cherry

Hardboard

主配線盤

Poplar

Red Oak

Wood Laminate (Plywood)

Carbon Fiber Composites

ファイバーグラス

Glass-filled Nylon

Yicen Precision offers a variety of finishing services designed to meet your project’s specific needs.

Removes sharp edges and burrs created during cutting to improve safety and provide a clean, finished look.

Uses high-pressure blasting with fine media to create a smooth, matte surface. Ideal for achieving a uniform finish and removing minor imperfections.

Removes oxidation, scale, and surface contaminants to restore and prepare metal surfaces after cutting.

Applies a uniform, subtle texture using abrasive brushes for an attractive and tactile surface.

Mechanically smooths surfaces to achieve a high-gloss, reflective finish—ideal for decorative or consumer-facing parts.

Smooths and rounds edges of small parts by vibrating them with abrasive media, improving finish and handling safety.

Applies a durable, protective coating that improves corrosion resistance and allows for various color options. Perfect for functional and aesthetic applications.

Adds a corrosion-resistant oxide layer to aluminum parts and enables a range of color options for both protection and aesthetics.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

Modern waterjet cutting relies on advanced systems that combine mechanical force, digital control, and material science for consistent, high-quality results.

Here’re the key technologies include:

Pure waterjet cutting uses only a pressurized stream of water, making it perfect for softer materials like rubber, foam, textiles, and plastics. With pressures reaching up to 60,000 PSI, it offers precision without material warping.

For harder materials such as metals, ceramics, composites, and stone-abrasive waterjet technology is used. Fine garnet particles are mixed with the water stream, enabling the cut to penetrate materials over 200 mm thick while maintaining excellent edge quality.

State-of-the-art CNC (Computer Numerical Control) technology drives the cutting head with micron-level accuracy. This ensures consistent shapes, intricate detailing, and repeatability critical for industries like aerospace, automotive, and architectural fabrication.

For high-volume orders, multi-head waterjet machines allow simultaneous cutting of identical parts, dramatically reducing production time while maintaining uniform quality.

Dynamic waterjet systems adjust for stream lag and taper, achieving sharp, vertical edges in thick materials and reducing the need for additional finishing.

From flawless edges to unmatched material versatility, waterjet cutting offers precision and performance that elevate every project.

Unlike laser or plasma cutting, waterjet cutting is a cold-cutting process. It prevents heat distortion, making it ideal for temperature-sensitive materials such as aluminum alloys, tempered glass, and specialty plastics.

From delicate fabrics to reinforced steel, waterjet cutting can handle over 1,200 different materials, including composites, ceramics, titanium, and marble. This makes it one of the most versatile cutting technologies available today.

With tolerances as tight as ±0.1 mm, waterjet cutting delivers smooth, burr-free edges, reducing or eliminating the need for secondary machining. This saves both time and money.

Waterjet cutting produces no hazardous fumes, reduces scrap waste, and allows nesting of parts to maximize raw material usage—often achieving up to 30% material savings compared to traditional cutting methods.

If you need a single prototype or thousands of identical parts, waterjet cutting adapts seamlessly. Its quick setup and minimal tooling requirements make it ideal for rapid iterations and urgent production runs.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Do you offer one-time custom cutting?Yes, we handle both custom prototypes and bulk production runs.

Yes, we handle both custom prototypes and bulk production runs.

Is it environmentally friendly?

Absolutely, waterjet cutting produces no toxic fumes and uses minimal waste.

Can you cut intricate shapes?

Yes, waterjet cutting offers high precision for complex and detailed designs.

How thick can waterjet cut?

Waterjet can cut materials up to 6 inches thick, depending on the type.

Is waterjet cutting safe for heat-sensitive materials?

Yes, since it’s a cold process, it’s ideal for materials that can’t withstand heat.