Yes, it’s perfect for cutting complex internal shapes with tight tolerances.

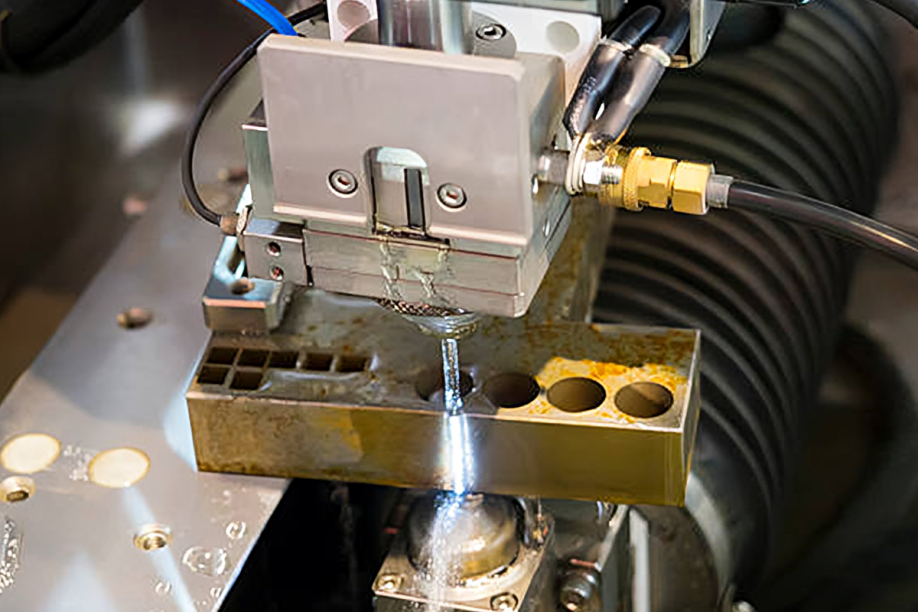

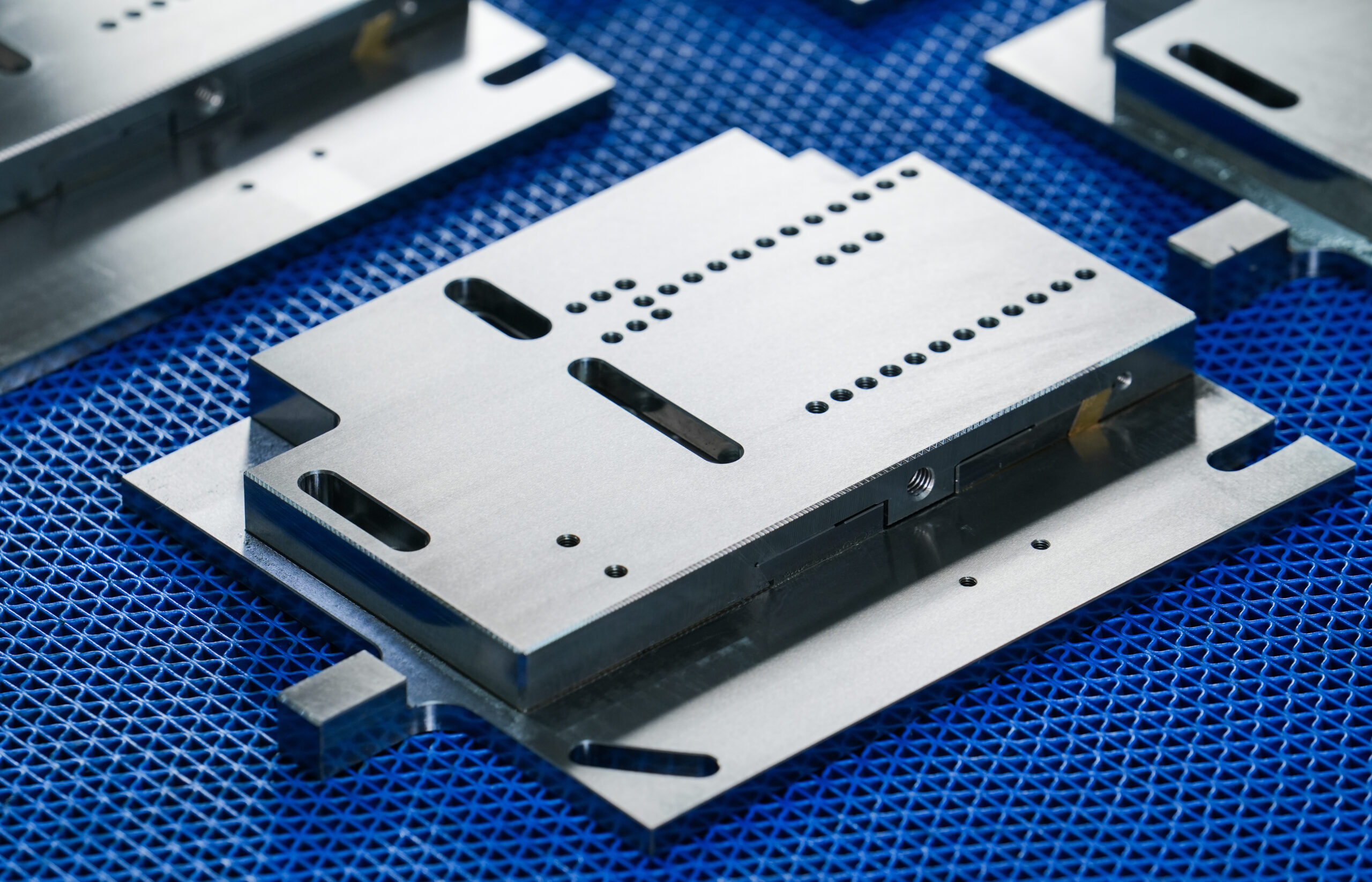

Experience unmatched precision with our modern wire cutting solutions. Using ultra-fine, durable wire electrodes, we shape complex metal parts with exact detail. This method produces smooth edges, minimizes material loss, and delivers reliable performance, making it ideal for specialized tooling, intricate molds, and components requiring strict dimensional accuracy.

Wire cutting is a precision process that uses an ultra-thin, electrically charged wire to slice through conductive materials with remarkable accuracy. It’s well-suited for producing intricate designs and maintaining strict tolerances, making it valuable in mold production, aerospace components, and other high-precision manufacturing applications.

| 特徴 | Standard Tolerance (mm) | High Precision (mm) | Ultra-Precision (mm) |

|---|---|---|---|

| Dimensional Accuracy | ±0.010 | ±0.005 | ±0.002 |

| Cutting Width (Kerf) | ±0.020 | ±0.010 | ±0.005 |

| Straightness | 0.005/100mm | 0.002/100mm | 0.001/100mm |

| Roundness | ±0.010 | ±0.005 | ±0.002 |

| Concentricity | ±0.010 | ±0.005 | ±0.002 |

| 表面仕上げ (Ra) | 1.6 µm | 0.8 µm | 0.2 µm |

| Minimum Feature Size | 0.25 mm | 0.15 mm | 0.05 mm |

We specialize in precision machining of detailed shapes and fine features in tough metals through advanced wire cutting. By using a charged wire, we maintain exact tolerances and flawless finishes without applying physical force, making it ideal for dies, tooling, and delicate parts needing distortion-free accuracy.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

D2

A2

H13

304

316

17-4 PH

440C

S7

M2

6061

7075

グレード2

グレード 5 (Ti-6Al-4V)

WC

C110 (Copper)

C932 (Bronze)

C360

C260

Inconel 625

インコネル718

EDM-grade graphite

Yicen Precision offers a variety of finishing options tailored to your project needs.

The default finish directly from the wire cutting process, featuring visible tool paths and minor surface roughness.

A matte, uniform finish is achieved by blasting the surface with fine media such as glass beads. This treatment is perfect for reducing glare and improving visual consistency.

A durable, oven-cured finish applied in a range of colors and textures.

Have a unique requirement? Submit an RFQ and our team will collaborate with you to develop a customized finishing solution.

Mechanical polishing delivers a smooth, mirror-like surface, ideal for parts that require both refined aesthetics and low friction.

An electrochemical treatment that smooths metal surfaces, reduces roughness, and enhances corrosion resistance, ideal for stainless steel components.

Removes sharp edges and residual burrs from the wire cutting process to improve handling safety and surface quality, especially for precision parts.

Removes surface contaminants and free iron from stainless steel.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

The wire cutting process transforms digital designs into flawless metal parts by using a fine, electrically charged wire to achieve intricate shapes, sharp edges and dimensional accuracy without physical contact.

Here’s a step-by-step breakdown:

Every wire cutting project starts with a precise CAD design of the required component. This design is converted into a CNC-compatible program that defines the cutting path. Accuracy in this stage is critical because even a fraction of a millimeter can affect the final fit and function of the part.

The selected workpiece is securely clamped onto the machine’s work table. The wire 0.1–0.3 mm in diameter is threaded through the starting hole or edge. Exact positioning ensures the cut begins at the right spot and follows the programmed path without deviation.

The wire passes through the workpiece, removing material using controlled electrical discharges rather than physical force. This method prevents distortion, even on thin or delicate parts. The process can achieve sharp corners, intricate curves, and detailed profiles that traditional cutting tools cannot match.

To maintain accuracy, the wire is continuously fed and kept under consistent tension during the cut. At the same time, a dielectric fluid flushes away debris and cools the cutting area. This keeps the process stable, prevents overheating, and ensures the surface finish remains smooth and free of burrs.

Once the cutting is complete, the part is carefully removed and cleaned. Skilled technicians perform a detailed dimensional inspection, often measuring tolerances as tight as ±0.002 mm. If needed, secondary passes or micro-finishing are applied to achieve the exact specifications and surface quality.

Wire cutting offers incredible precision, but like any advanced manufacturing process, it comes with its own set of challenges. At Yicen Precision, we’ve spent years perfecting our methods to overcome these issues, ensuring every component meets the highest standards.

Here’s a closer look at the common challenges and how we solve them.

Challenge: Fine wires, especially those just 0.1–0.25 mm thick, can snap when cutting hard or thick metals. This not only interrupts production but also risks damaging the part.

Our Solution: We use optimized machine settings for tension, voltage, and feed rate, combined with premium wire materials. This has reduced breakage rates by over 30%, saving both time and material.

Challenge: Excessive heat during the cutting process can alter the microstructure of certain alloys, potentially weakening the part or affecting its precision fit.

Our Solution: Our machines use short, controlled electrical pulses and advanced cooling systems to keep heat generation to a minimum. This maintains the original material properties and eliminates the risk of heat distortion.

Challenge: During cutting, tiny metal particles (swarf) can accumulate in the gap between the wire and the workpiece, reducing accuracy and slowing down the process.

Our Solution: We employ multi-directional high-pressure flushing to clear debris continuously. It ensures a clean cutting path and maintains tolerance consistency throughout the job.

Challenge: When tolerances are as tight as ±0.002 mm, even small factors like material hardness variations or temperature changes can cause deviations.

Our Solution: Our CNC systems include adaptive control features that automatically adjust feed and discharge settings in real time. This allows us to hold tolerances with exceptional repeatability, even on complex shapes.

Challenge: Intricate profiles or deep internal cuts can take longer, increasing production costs and delivery time.

Our Solution: We use multi-pass cutting techniques, a roughing pass for speed followed by fine passes for accuracy and finish. This approach improves surface quality while reducing overall machining time by up to 20%.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Can wire EDM cut internal features?

Yes, it’s perfect for cutting complex internal shapes with tight tolerances.

Is there any contact with the material?

No, it’s a non-contact process that uses electrical sparks for cutting.

Does wire cutting cause heat damage?

No, it’s a cold cutting process that avoids thermal distortion.

How precise is wire EDM cutting?

It can achieve tolerances as tight as ±0.002mm.

Can I use wire cutting for small quantity projects?

Yes, it’s ideal for prototypes and small production runs.