We follow strict internal QC procedures, maintain material certifications, and provide inspection reports upon request.

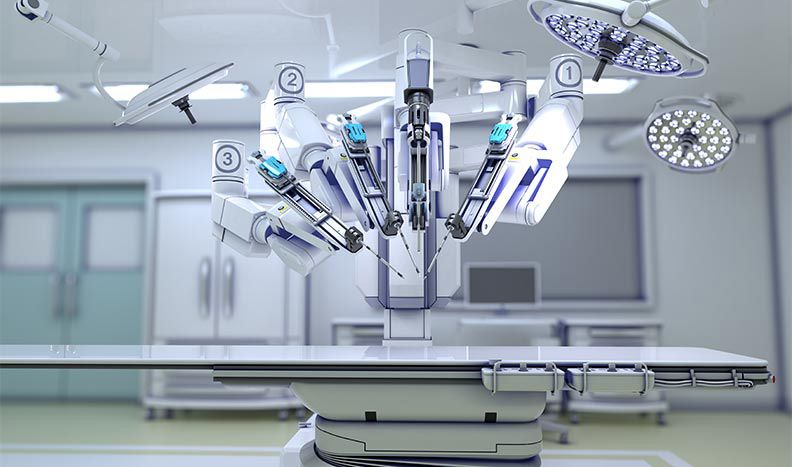

At Machining services, we understand the critical importance of precision and safety in medical device manufacturing. Our CNC machining services are ideal for producing high-quality, reliable components for devices used in diagnostics, surgical tools, implants, and more. With a focus on tight tolerances, biocompatible materials, and regulatory compliance, we ensure every part meets the rigorous standards of the healthcare industry. Whether you’re working on prototypes or full production runs, we provide machining solutions that help advance patient care and medical technology.

We specialize in precision CNC machining for the medical device industry, where reliability, accuracy, and safety are paramount. Our expert team transforms complex CAD designs into high-quality, functional components for medical equipment, implants, and diagnostic tools, all while adhering to stringent regulatory standards.

We offer end-to-end solutions, from prototype development to large-scale production, ensuring each part meets exacting tolerances and performance requirements. Using a variety of materials, including medical-grade stainless steel, titanium, and biocompatible plastics, we deliver custom parts that are reliable, durable, and safe for medical applications.

Whether you’re developing life-saving devices or advanced healthcare equipment, our machining services ensure precision and consistency for devices that improve patient outcomes.

We provide precision-machined components for medical devices, ensuring compliance with strict quality standards and supporting innovation in healthcare technology.

We provide precision-machined components for medical devices, ensuring compliance with strict quality standards and supporting innovation in healthcare technology.

高度な技術と比類のない効率性を備えた高精度CNC製造。

最新鋭の機械を使用した合理化されたCNC生産により、安定した品質を実現。

複雑なCNC部品の専門的な加工と組み立てを一箇所で行うことができます。.

完全自動化されたCNCオペレーションにより、高速、高精度、高信頼性の加工を実現。

最高品質のCNCパーツをスピードと精度で提供するために最適化されています。

シームレスなワークフローと優れた結果をもたらすエンドツーエンドのCNC製造。

We offer metal alloys and high-performance plastics for medical device parts, ensuring durability, safety, and compliance for prototyping and production needs.

アルミニウム:5052、6061-T6、7075-T6、2024-T351

Titanium: Grade 1, Grade 2, Grade 5

Brass & Copper Alloys: C360, Copper C110, C101

Thermoplastics: PC, ABS, PLA, PEEK, Ultem 1010, PA 12

Commodity polymers: HDPE, UHMW-PE , Garolite G-10, FR4

Our surface finishes, including anodizing and electroplating, enhance corrosion resistance, biocompatibility, and wear resistance for medical device components.

陽極酸化処理

機械加工

ブレッド・ブラスト

ブラックオキサイド

電解研磨

無電解ニッケルめっき

クロメート化成処理

微細加工

パウダーコーティング

研磨

スムーズな加工

See why clients rely on Yicen Precision for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precisionは、トップクラスのCNC機械加工サービスを提供してくれました。彼らの細部への配慮と効率性は比類のないものです。

迅速な納期と精密な加工。Yicen Precisionは、常に時間通りに高品質の仕事をお届けします。

卓越したサービスと信頼できる加工。Yicen PrecisionはすべてのCNC関連プロジェクトのための私達の頼れるサプライヤーです。

素晴らしいコミュニケーションと優れた職人技。Yicen Precisionは常に私たちの厳しい仕様を満たしています。

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

In the medical industry, precision isn’t optional it’s life-critical. From surgical tools and diagnostic equipment to implantable components and wearable devices, every part must meet the highest standards of accuracy, safety, and reliability.

で Yicen MPrecision, we specialize in high-precision CNC machining for medical devices. We work with OEMs, startups, and medtech innovators to deliver mission-critical components that meet strict regulatory and performance requirements.

Medical components often require:

Our advanced CNC capabilities ensure we meet these demands—whether for a single prototype or a high-volume production batch.

We produce durable, corrosion-resistant tools used in operating rooms and outpatient procedures, including:

All parts are machined to surgical-grade precision with polished finishes or coatings as needed.

We machine metal and polymer components used in permanent and temporary implants, such as:

We work with titanium, PEEK, and surgical-grade stainless steels all known for their biocompatibility.

Modern imaging and diagnostic tools rely on intricate mechanical parts for movement, calibration, and signal processing. We provide:

Tight tolerance and stable materials ensure accuracy in every scan or measurement.

As medtech becomes more mobile, we support developers with:

We offer machining for medical-grade plastics and metals, and finishes suitable for skin contact and daily use.

At Yicen Precision, we understand the medical device lifecycle from rapid prototyping and regulatory testing to full-scale production. We provide:

Need a testable prototype or clinical trial sample? We deliver functional parts in days with precision machining and fast-turn setups.

Our engineers work with your team to refine designs, reduce machining complexity, and ensure parts can be consistently reproduced.

We maintain strict process controls, documentation, and material traceability to help you meet ISO and FDA requirements.

When you’re ready to scale, we can ramp up production to thousands of units without compromising quality, finish, or traceability.

We work with companies developing and manufacturing:

If it needs to be precise, sterile, and strong we’ve likely machined it.

Partner with Yicen Precision to ensure your medical devices are built with unmatched precision, reliability, and care.

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

How do you ensure quality and compliance?

We follow strict internal QC procedures, maintain material certifications, and provide inspection reports upon request.

Do you provide surface finishes for hygiene and sterilization?

Yes. We offer polishing, electropolishing, passivation, and coatings that meet hygienic and sterilization requirements.

Can you help with prototyping for FDA submissions?

Absolutely. We offer rapid CNC prototyping with full documentation to support design verification and clinical testing phases.

What tolerances can you achieve for surgical tools?

We can achieve tolerances down to ±0.005 mm, ideal for high-precision surgical and orthopedic instruments.

Can you machine parts suitable for implantation?

Yes. We machine titanium, PEEK, and 316L stainless steel components for use in implantable and biocompatible medical devices.