Not typically. Brushing is suitable for aluminum, but electropolishing is generally reserved for stainless steel and certain other metals.

At Yicen Machining, we combine mechanical brushing and electropolishing techniques to create clean, smooth, and high-performance finishes for your metal parts. Connect with Yicen Machining to upgrade your components with a professional-grade finish.

| パラメータ | 仕様 |

|---|---|

| Surface Roughness (Ra) | 0.2 – 0.8 µm |

| Compatible Materials | Stainless steel, aluminum, brass |

| Dimensional Tolerance Impact | Minimal changes, removes micro-burrs |

| Visual Appearance | Smooth, high-gloss finish |

| Mechanical Properties | Enhanced corrosion resistance, reduced surface friction |

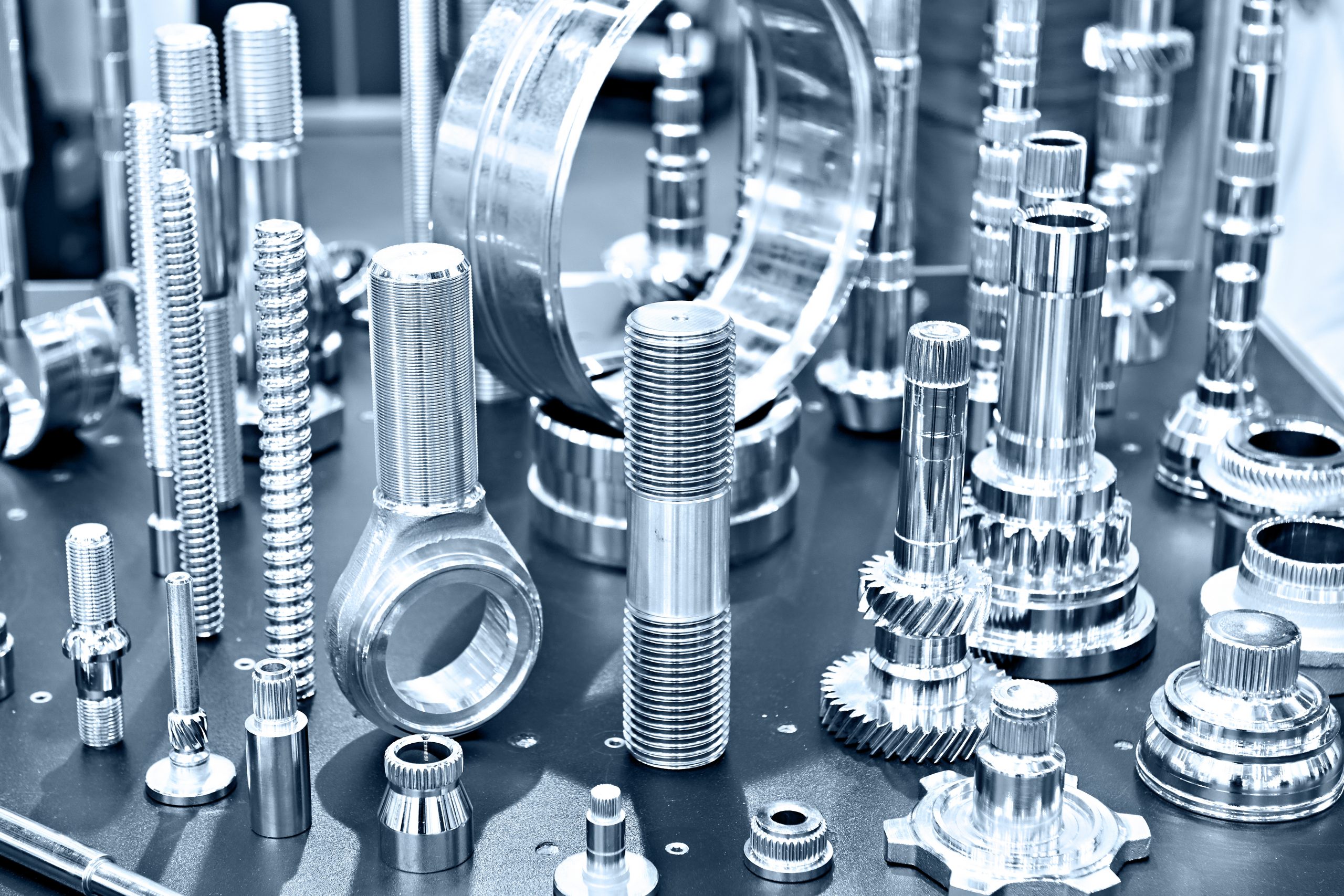

| Best Applications | Medical, aerospace, food-grade components |

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

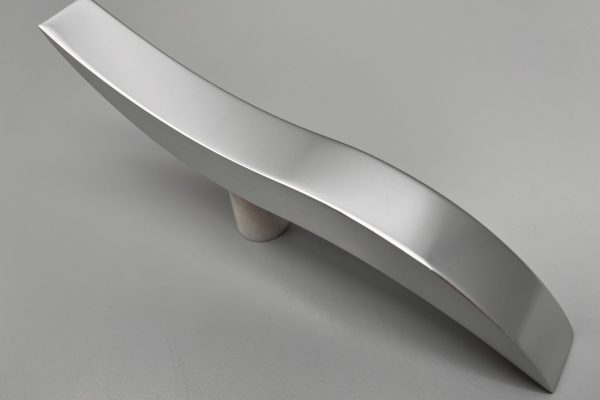

The final look of a component can say a lot about its quality. At Yicen Machining, we offer advanced brushed and electropolished finishes that not only elevate appearance but also enhance the part’s performance in critical applications. Whether you’re targeting a refined visual texture or improved functional surfaces, our dual-finishing process delivers results you can trust.

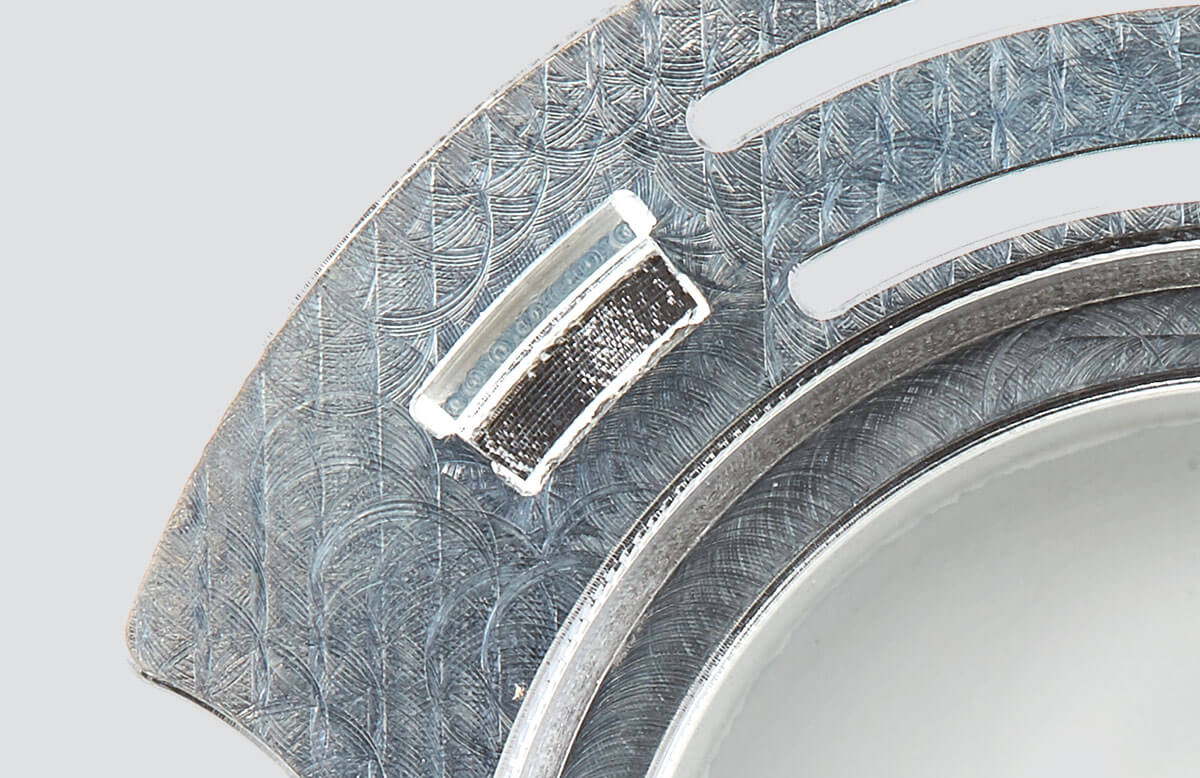

Unlike mechanical processes, electropolishing uses an electrochemical method to smooth and passivate metal surfaces. It carefully removes a thin surface layer, evening out microscopic peaks and valleys for a bright, hygienic, and corrosion-resistant finish. Particularly effective on stainless steel, electropolishing is a go-to solution for parts requiring sterility and precision.

Brushing sets the stage removing inconsistencies and creating uniformity. Electropolishing then refines that surface by adding brightness, smoothness, and added protection. Together, they produce components that perform reliably and look exceptional.

Yicen Machining adjusts each process to meet your unique specs, whether you need medical-grade finishes or visually striking consumer parts.

Brushed + electropolished parts are commonly used in:

We’ve built our reputation on delivering dependable, visually impressive finishes across various industries. Our finishing process is backed by:

Brushed and electropolished finishes don’t just look good they protect your investment and improve part function in high-demand environments.

Partner with Yicen Machining today to achieve cleaner, smoother, longer-lasting metal components.

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Can aluminum be electropolished?

Not typically. Brushing is suitable for aluminum, but electropolishing is generally reserved for stainless steel and certain other metals.

What’s the expected finish look?

Brushed parts have a matte grain, while electropolished ones are glossy. Combined, the result is sleek and professional.

Does this process work for food or medical components?

Yes. Electropolished stainless steel meets hygiene standards required for sterile and clean-room environments.

Will electropolishing affect critical dimensions?

It removes only a very thin layer, but it can slightly alter high-precision features. We account for this during process planning.

Is brushing necessary before electropolishing?

Not always, but brushing improves uniformity and ensures cleaner, more consistent electropolishing results.