Send us your files via our online portal or reach out to our support team. We’ll review your needs and deliver a custom quote.

Our Vapor smoothing enhances 3D printed parts by improving surface finish. Contact Yicen Machining today to elevate your 3D prints with polished appearance.

Vapor smoothing is a post-processing technique that uses heated solvents to smooth out surface imperfections on 3D printed parts, enhancing their finish and improving their appearance and durability.

| パラメータ | 仕様 |

|---|---|

| Surface Roughness (Ra) | 0.4 – 1.2 µm |

| Compatible Materials | ABS, ASA, Polycarbonate, Nylon, TPU |

| Dimensional Tolerance Impact | ±0.1 – ±0.3 mm variation due to material swelling/shrinkage |

| Visual Appearance | Glossy, uniform finish with reduced layer lines |

| Mechanical Properties | Slight increase in impact resistance, minimal strength reduction |

| Chemical Used | Acetone, Methyl Ethyl Ketone (MEK), or proprietary vapor agents |

| Best Applications | Consumer products, medical enclosures, automotive parts, prototypes |

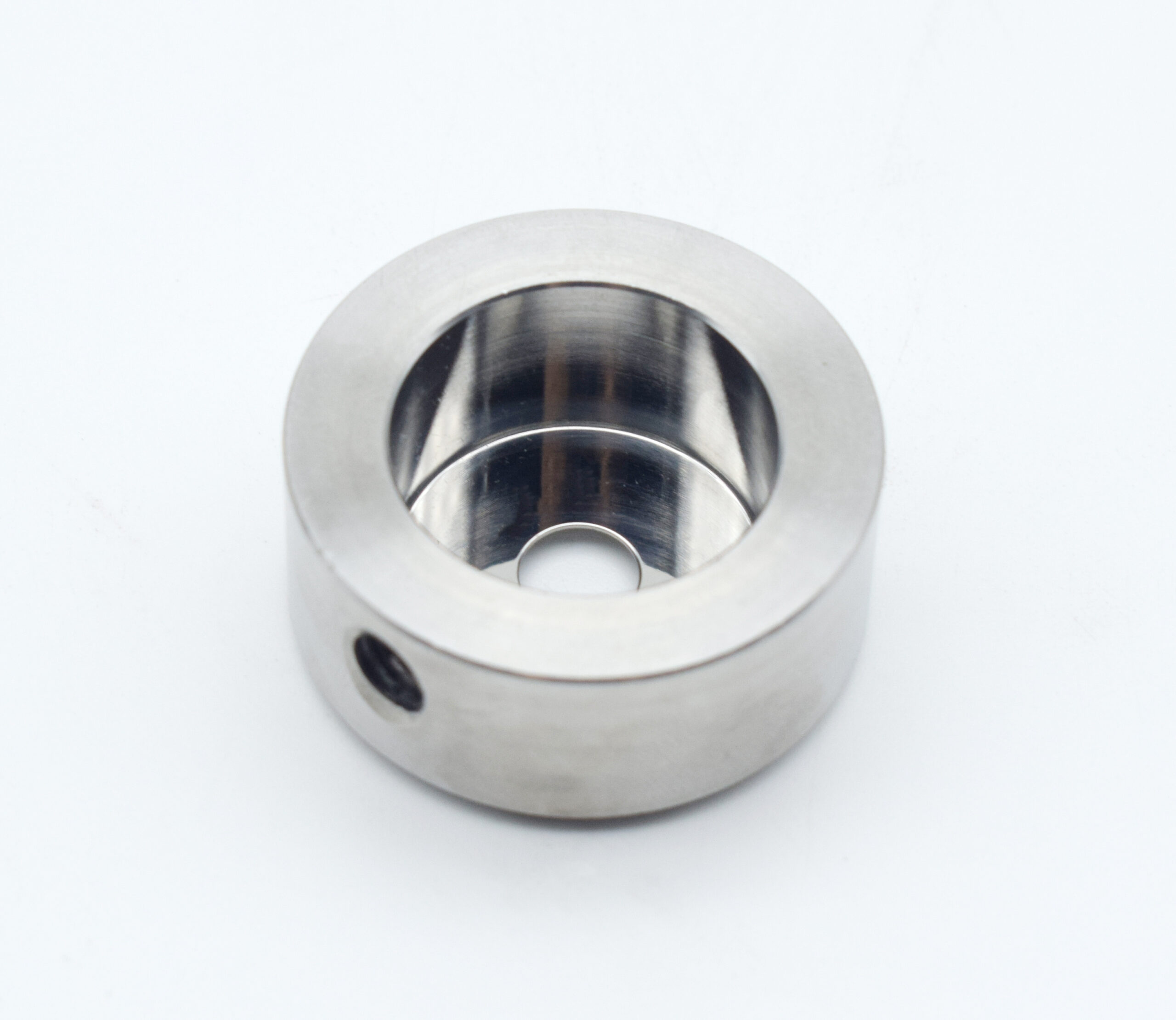

Explore our Vapor Smoothing Finishing Gallery to see the transformative effects of this advanced post-processing technique. From enhanced smoothness to improved aesthetics, discover how vapor smoothing elevates the quality of 3D printed components.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

Vapor smoothing is an advanced finishing process that significantly improves the surface quality of 3D printed components. At Yicen Machining, we use controlled solvent vapor exposure to transform rough, layered prints into smooth, glossy parts with a high-end, injection-molded look.

This technique is ideal for enhancing both the function and appearance of parts made from FDM, SLS, and MJF technologies perfect for prototypes and production-ready products alike.

Vapor smoothing involves placing parts in a specialized chamber where vaporized solvents are introduced. These vapors slightly melt the outermost layers of the material, softening sharp textures and smoothing rough layer lines. Once the solvent is purged, the part re-solidifies with a uniform, sealed finish.

The entire process is monitored to ensure no distortion while achieving consistent results across all surfaces.

Yicen Machining recommends vapor smoothing for any application requiring:

This finishing option provides both a cosmetic boost and functional benefits, especially in parts that interact with users or liquids.

Yicen Machining’s vapor smoothing process is used across a range of industries:

Our vapor smoothing capabilities are built for quality, efficiency, and repeatability. Clients choose us for:

Whether it’s a small batch of prototypes or a full production run, we tailor our process to meet your exact requirements.

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

How can I submit parts for vapor smoothing?

Send us your files via our online portal or reach out to our support team. We’ll review your needs and deliver a custom quote.

Can I post-process smoothed parts further?

Yes. The polished surface accepts paint, plating, and coatings very well

Is vapor smoothing safe for end-use parts?

Absolutely. In fact, it can enhance durability and surface sealing, making parts more reliable in use.

Will the process alter my part’s dimensions?

Minimal change occurs—typically within ±0.1 mm—but we account for this when finishing parts with tight tolerances.

Which printing methods benefit most from vapor smoothing?

FDM, SLS, and MJF prints—especially those with noticeable layer stepping—see the greatest improvement.