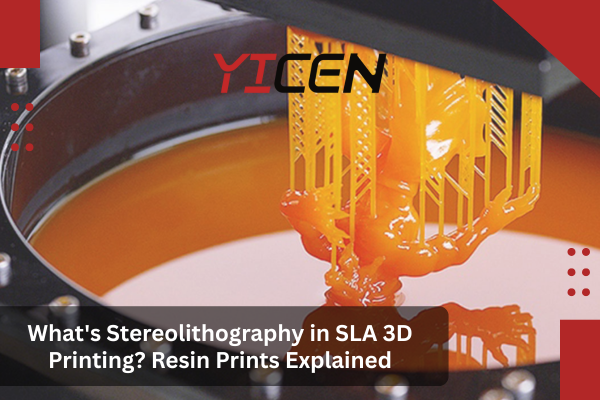

SLA 3D printing transforms digital 3D models into physical objects using light to cure photosensitive polymers. Chuck Hull developed this revolutionary stereolithography 3D printing technology in 1984, making it the first 3D printing technology ever commercialized.

Today’s SLA 3D printing market reaches $1.8 billion globally, with aerospace and medical sectors driving adoption. This additive manufacturing technology creates parts with exceptional smooth surface finish and Ra 0.05 µm surface roughness, significantly superior to traditional manufacturing methods.

What is SLA Printing?

Stereolithography is an additive manufacturing process that uses ultraviolet light to cure photosensitive liquid resin into solid plastic. This popular 3D printing method builds objects resin layer by layer, with each layer typically 25-100 micrometers thick. Modern SLA 3D printers achieve high resolution down to 10 micrometers.

The technology relies on photopolymerization – where UV laser to cure triggers molecular chains to form bonds across layers. SLA 3D printing offers isotropic mechanical properties, meaning strength remains consistent across all directions, making this form of 3D printing superior to other 3D printing methods for functional applications.

How Does SLA Printing Work?

について SLA process begins with a digital 3D model sliced into thin horizontal layers. SLA systems position the build platform precisely in the resin tank, where light source to cure liquid photopolymer resin creates each layer.

Step-by-Step SLA Process

- Model Preparation: 3D models convert to STL format and slice into layers

- Layer Curing: Laser to cure liquid resin selectively according to geometry

- Platform Movement: Build platform moves as the process is repeated

- Support Removal: SLA 3D printed parts are cleaned and supports removed

- Post-Curing: Additional exposure completes curing when printing is complete

Printing speed varies from 1-15 seconds per layer depending on SLA technology. Laser systems trace layers point-by-point, while projector systems cure the resin for entire layers simultaneously.

Types of SLA 3D Printing Technologies

Traditional Laser SLA

Top-down SLA uses galvanometer mirrors directing focused UV beams across resin materials. Professional SLA machines ような 3D Systems ProJet achieve ±0.05mm accuracy over 250mm builds, demonstrating precise 3D capabilities.

Digital Light Processing (DLP)

DLP technology projects entire layers using digital mirror devices. Texas Instruments’ DLP chipsets enable accurate 3D printing with 35-micron pixels, achieving faster printing speed of 30mm/hour vertically.

Masked Stereolithography (MSLA)

Desktop SLA printers commonly use MSLA systems with LCD screens to mask UV LED arrays. Consumer SLA printers like Anycubic Photon achieve 0.01mm resolution, though screens require replacement every 500-2000 hours.

SLA Printing Materials and Properties

| SLA Materials | Tensile Strength (MPa) | Elongation (%) | 3D Printing Uses |

| Standard SLA Resin | 35-65 | 4-7 | Prototypes, models |

| Tough Resin | 45-85 | 12-25 | Functional parts |

| Flexible Resin Materials | 1.5-4 | 90-150 | Gaskets, rubber parts |

| Castable Resin | 40-60 | 2-6 | Investment casting |

| Biocompatible | 50-70 | 5-15 | Medical devices |

SLA 3D printing materials chemistry determines final material properties. Acrylate-based formulations offer fast curing but limited toughness, while epoxy resin materials provide better mechanical properties but require longer exposure times for used SLA applications.

Advantages of SLA 3D Printing

Superior Surface Quality

Advantages of SLA 3D printing include achieving surface roughness of Ra 0.05-0.15 µm straight from the SLA printer, eliminating secondary machining. Automotive companies use SLA parts directly for wind tunnel testing without additional finishing.

Exceptional Detail Resolution

SLA excels at creating 3D objects by successively building layers with minimum feature sizes reaching 0.1mm. Jewelry manufacturers create intricate lattice structures impossible with traditional methods. Medical device companies 3D print parts with small features requiring sub-millimeter accuracy.

Wide Range of Applications

Over 200 commercial photopolymer resin formulations exist, providing a wide range of applications. SLA 3D printing uses include flame-retardant grades for aerospace, USP Class VI materials for medical devices, and high-temperature formulations.

Limitations of SLA Printing

Build Volume Constraints

Desktop SLA printers typically offer 150x150x200mm build volumes. Industrial SLA systems reach 1500x750x550mm but cost $500,000+. Large assemblies require sectioning and bonding.

Material Handling Requirements

Liquid resin emits volatile organic compounds requiring ventilation systems. Skin contact causes sensitization in 15-20% of users according to occupational health studies. Personal protective equipment becomes mandatory for making SLA operations safe.

Post-Processing Needs

SLA printed parts require washing in isopropyl alcohol and post-curing for 30-120 minutes. Support removal can damage fine features if not performed carefully on resin 3D print components.

SLA vs Other 3D Printing Technologies

| 3D Printing Technologies | Surface Roughness (Ra µm) | 材料 | Cost per Part |

| SLA 3D printing | 0.05-0.15 | 200+ | $5-50 |

| 多重伝送装置 | 5-25 | 1000+ | $1-10 |

| SLS 3D | 8-15 | 50+ | $10-100 |

| MJF | 3-8 | 20+ | $8-80 |

SLA 3D printing is widely recognized for delivering 10x better surface quality than FDM technology. Printing methods vary significantly – FDM creates strong parts along layer planes but weak between layers, while characteristics of SLA include uniform strength in all directions.

Applications of SLA Printing

Prototyping and Product Development

SLA 3D printing applications reduce product development cycles from weeks to days. ラピッドプロトタイピング enables design validation before tooling investment. Apple reportedly uses stereolithography process for iPhone prototype housing development.

Medical and Dental Applications

Dental laboratories process over 10 million SLA 3D printed parts annually according to 3D Systems market data. FDA-cleared resin materials enable direct patient contact with 99% dimensional accuracy for surgical guides and anatomical models.

Jewelry and Art

Investment casting using SLA printed patterns produces jewelry with intricate details. Burnout temperatures of 500°C leave no residue in ceramic molds, demonstrating the range of applications possible with specialized resin materials.

Industrial Tooling

Automotive manufacturers create checking fixtures using SLA technology. Boeing employs stereolithography process for composite layup tools in aircraft production, eliminating tool wear issues common with traditional manufacturing methods.

Yicen Precision’s SLA 3D Printing Services

Yicen Precision operates multiple SLA systems with 50-micron resolution capabilities. Their SLA 3D printing service includes same-day turnaround for urgent rapid prototyping requirements. Quality certifications include ISO 9001:2015 and ISO 13485.

Their 3D printing service provides DFM analysis, resin materials selection guidance, and comprehensive post-processing, ensuring optimal results for diverse 3D manufacturing requirements across industries.

Best Practices for SLA Printing Success

Design Optimization

Wall thickness recommendations range 0.8-3.0mm depending on SLA resin type. Hollow designs require 2-3mm diameter drain holes preventing uncured liquid resin entrapment. Draft angles facilitate support removal from print parts.

Support Structure Strategy

Tree supports reduce material usage by 30% compared to block supports while enabling easier removal. Critical angles exceeding 45 degrees require additional reinforcement for successful 3D printing process.

Post-Processing Excellence

Washing removes uncured oligomers that cause skin sensitization. Ultrasonic cleaning reduces wash time from 20 minutes to 5 minutes while improving surface quality. Post-curing duration directly affects final mechanical properties.

Troubleshooting Common SLA Printing Issues

Layer Adhesion Problems

Insufficient exposure causes poor layer bonding and delamination. Temperature affects curing kinetics – optimal range maintains 25-30°C during 3D printing process. Baseline exposure tests determine optimal parameters for each resin materials batch.

Support Failure

Heavy parts require increased support density near attachment points. Raft thickness of 2-5 layers prevents platform adhesion failures while balancing removal ease against print parts success rates.

Surface Quality Issues

FEP film replacement every 500-1000 layers maintains optimal transparency. Cloudy films reduce UV transmission by 20-30%, causing incomplete curing and surface artifacts on SLA parts.

Future Trends in SLA Printing Technology

Advanced Materials Development

Ceramic-filled photopolymer resin formulations achieve 65% ceramic loading for high-temperature applications. Conductive resin materials enable direct 3D print of electronic circuits. Research focuses on recyclable formulations.

Increased Build Speeds

Continuous Liquid Interface Production (CLIP) technology achieves 100x faster speeds than traditional SLA 3D printing. Multi-laser arrays parallelize curing processes, enabling production systems to reach 1000+ 3D printing parts daily.

Enhanced Accuracy

Adaptive optics compensate for thermal distortion during large builds. Real-time monitoring using optical coherence tomography detects defects, maintaining ±10-micron accuracy across wide range of applications.

Environmental Considerations

Sustainable Practices

Photopolymer resin waste requires specialized disposal through certified contractors at $2-5 per pound. Manufacturers develop bio-based resin materials reducing petroleum dependency by 40-60%.

Used SLA resin recycling remains challenging due to cross-contamination. Research initiatives focus on chemical recycling methods recovering base monomers for repolymerization.

Cost Analysis and Economic Benefits

Initial Investment

Entry-level desktop SLA printers start at $200 for 2K LCD systems. Professional units range $3,000-15,000, while industrial SLA machines exceed $100,000 but offer production-grade capabilities.

Operating Expenses

SLA resin costs vary from $50-500 per liter depending on performance requirements. Standard resin materials average $80-120 per liter. Total operating costs average $0.15-2.50 per cubic centimeter including maintenance.

結論

SLA 3D printing technology continues advancing with faster speeds and improved accuracy. Companies integrating stereolithography 3D printing report 40-60% reduction in rapid prototyping costs and 70% faster development cycles. Understanding SLA technology fundamentals enables informed implementation decisions across diverse 3D manufacturing applications.

What makes SLA 3D printing different from other 3D printing methods?

SLA 3D printing uses liquid resin cured by ultraviolet light to cure photosensitive polymers, creating exceptionally smooth surface finish with 0.05-0.15 µm roughness compared to 5-25 µm for other 3D printing technologies.

How long does SLA 3D printing take?

Printing speed depends on part height, not complexity. Typical ranges span 2-12 hours for desktop SLA printers. Post-processing adds 1-3 hours for washing and curing SLA printed components.

Are SLA 3D printed parts strong enough for functional use?

Modern tough resin materials achieve 45-85 MPa tensile strength, comparable to injection-molded ABS. However, UV degradation occurs over time without proper coating protection.

What safety precautions are needed for SLA 3D printing?

Liquid resin requires nitrile gloves, safety glasses, and adequate ventilation. Exposure limits of 0.1 ppm exist for common photoinitiators used for SLA printing operations.

Can SLA printers use different types of resin?

Most SLA 3D printers accommodate various photopolymer resin formulations with exposure parameter adjustments. Complete resin tank cleaning prevents cross-contamination between resin materials.

How accurate are SLA 3D printed parts?

Desktop SLA printers achieve ±0.1-0.2mm accuracy over 100mm dimensions. Industrial SLA systems reach ±0.05mm with proper calibration, demonstrating precise 3D manufacturing capabilities.

Citations and References

- Wohlers Associates. “Wohlers Report 2024: 3D Printing and Additive Manufacturing Global State of the Industry.” Fort Collins, CO, 2024.

- National Institute of Standards and Technology. “Photopolymer Additive Manufacturing Alliance Research.” NIST.gov, March 2025.

- Chen, M., et al. “Mechanical Properties of UV-Cured Photopolymers for SLA Applications.” Journal of Materials Science, vol. 58, 2023, pp. 1247-1265.

- ISO/ASTM 52900:2021. “Additive Manufacturing – General Principles – Fundamentals and Vocabulary.”

- Hull, Charles W. “Apparatus for Production of Three-Dimensional Objects by Stereolithography.” US Patent 4,575,330, 1986.

- 3D Systems Corporation. “Market Analysis: Healthcare Applications of Stereolithography.” Rock Hill, SC, 2024.

- Zhang, L., et al. “Occupational Health Considerations in Photopolymer 3D Printing.” Industrial Hygiene Quarterly, vol. 29, no. 3, 2024.