Absolutely, we provide quick turnaround prototyping services.

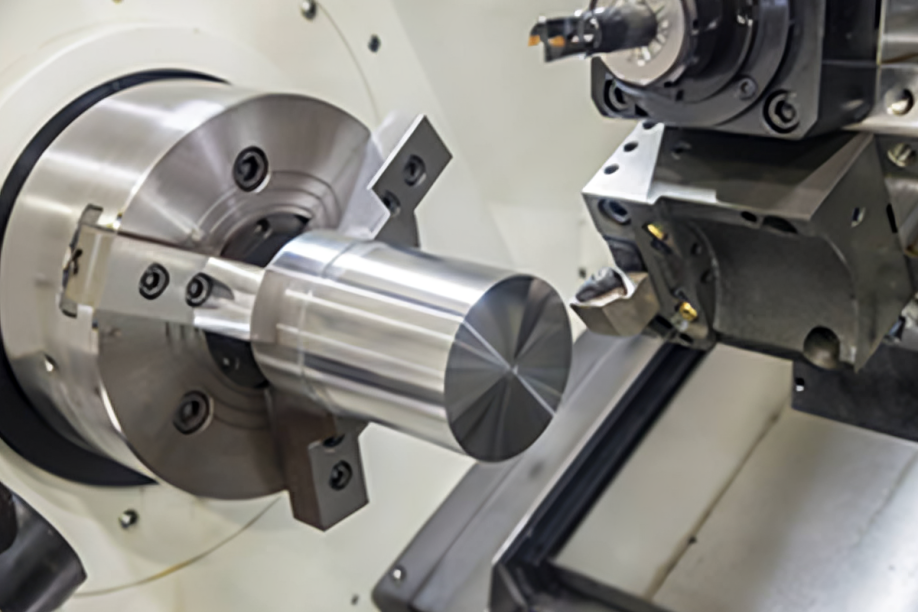

Yicen Precision delivers industry leading CNC turning services, engineered for intricate geometries and rapid production. We provide dependable, high-quality parts in diverse metals and plastics, meeting the stringent requirements of aerospace, medical, and industrial sectors. Delivering reliable accuracy, fast turnaround, and uncompromised quality with every part we manufacture.

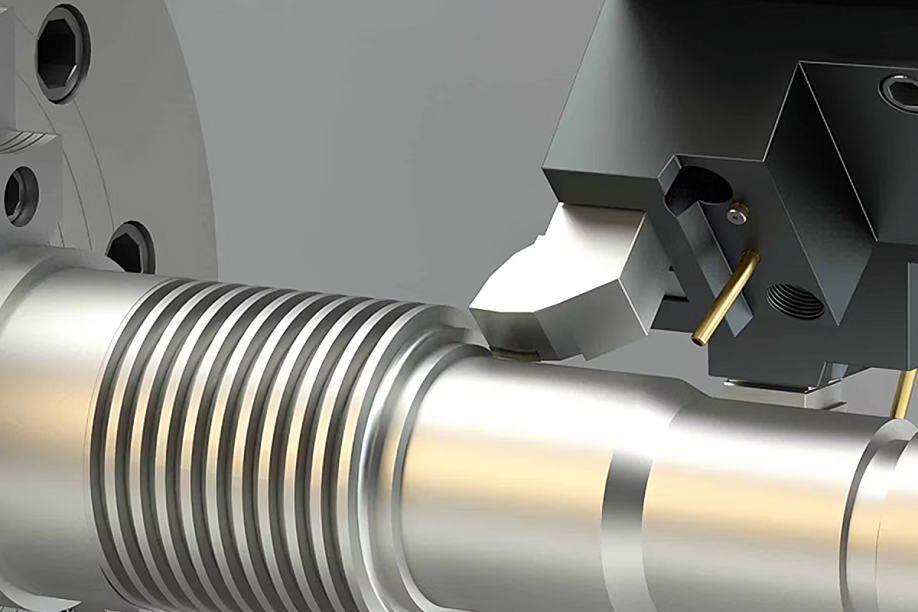

CNC turning is a precision machining technique that shapes cylindrical parts by rotating the material while a cutting tool removes excess. Using advanced CNC lathes, this process ensures exceptional accuracy, fine surface finishes, and repeatable results, ideal for manufacturing components like shafts, bushings, and threaded mechanical parts.

| Merkmal | Standard Tolerance (mm) | High-Precision Tolerance (mm) |

|---|---|---|

| Diameter (Outer & Inner) | ±0.05 | ±0.005 |

| Length | ±0.1 | ±0.01 |

| Straightness | 0.1/100mm | 0.01/100mm |

| Roundness | 0.05 | 0.005 |

| Concentricity | 0.05 | 0.005 |

| Thread Tolerance | ISO 965 (6g/6H) | Custom fit |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm |

Our CNC turning services are optimized for producing high-precision rotational parts with fine surface finishes. Using advanced turning centers, we machine everything from basic shafts to intricate, multi-featured components. This process ensures consistent dimensional accuracy and repeatability, making it a perfect fit for demanding industries such as aerospace, automotive, and heavy equipment manufacturing.

Ingenieure und führende Hersteller vertrauen auf Yicen Precision, wenn es um schnelle Iterationen und langlebige, leistungsstarke Teile geht. Ob für Prototypen oder für die Großserienproduktion, unsere umfangreiche Materialauswahl gewährleistet Präzision, Festigkeit und Zuverlässigkeit für jedes CNC-Bearbeitungsprojekt.

Aluminum 5052

Aluminum 7075 & 7075-T6

Aluminum 6063-T5

Aluminum 7050-T7451

Aluminum MIC-6

Aluminum 6061-T6

Aluminum 2024-T3

Brass C360

Brass 260

C932 M07 Bearing Bronze

H59

H60

ABS

Acetal [Delrin]

Acrylic, G-10 Garolite

Nylon 6/6

PEEK

Polycarbonat

PTFE [Teflon]

Polypropylene

Ultra-High Molecular Weight Polyethylene

Alloy Steel 4130

Alloy Steel 4140

ASTM A36

Stainless Steel 15-5

Stainless Steel 17-4

Stainless Steel 18-8

Stainless Steel 303

Stainless Steel 304

Stainless Steel 316/316L

Stainless Steel 416

Stainless Steel 420

Steel 1018

Steel A36

Titanium Grade 2

Titanium 6Al-4V

Zinc Sheet Alloy 500

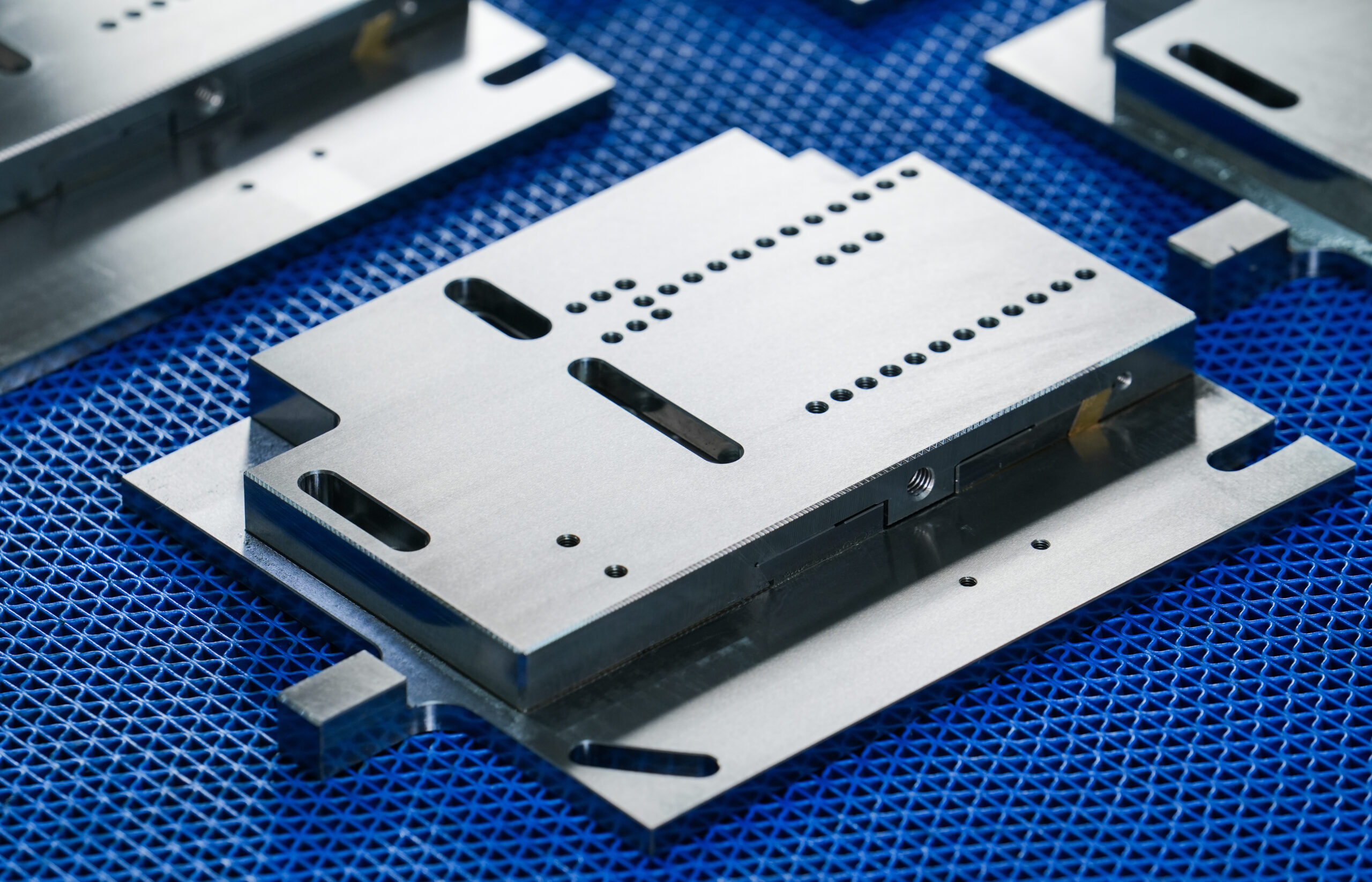

Precision-turned parts benefit from specialized surface treatments that enhance strength, durability, and overall performance. These treatments are ideal for optimizing the functionality of shafts, bushings, and cylindrical components.

The quickest and most economical option, leaving visible tool marks and potentially sharp edges or burrs. Surface roughness is approximately 125 µin Ra, and burrs can be removed upon request.

A thick chromium coating that boosts hardness, wear resistance, and durability. Perfect for high-stress parts like shafts and pistons.

A thin, electroplated nickel layer that enhances wear and corrosion resistance. Provides a bright, attractive finish for functional parts.

A chemical treatment that creates a dark, matte black surface on steel parts. Offers mild corrosion resistance and reduces light reflection.

A smooth, glossy finish achieved by mechanical buffing. Ideal for decorative parts requiring enhanced shine and low roughness.

A linear, satin-like texture created using abrasive belts or brushes. It reduces minor imperfections and offers a clean, decorative appearance.

Need a specific finish? Submit an RFQ, and we’ll work with you to find a tailored solution for your project.

Creates a smooth, matte finish by media-blasting, typically with glass beads, offering an improved aesthetic and uniform surface texture.

Wir sind darauf spezialisiert, Ihre Ideen mit beispielloser Schnelligkeit und Präzision in hochwertige, funktionale Komponenten umzusetzen. Mit fortschrittlicher Technologie und fachmännischem Können stellen wir Teile her, die selbst die komplexesten Spezifikationen erfüllen.

When it comes to producing high-quality cylindrical components with exceptional accuracy, CNC turning is the gold standard. At Yicen Precision, we specialize in CNC turning services that deliver precise, consistent, and complex parts for industries where reliability and exactness matter most.

CNC turning is a subtractive manufacturing process where a cutting tool removes material from a rotating workpiece to create symmetrical shapes such as shafts, bushings, and threaded components. Controlled by computer software, this method offers superior precision and repeatability compared to manual turning.

Our advanced CNC turning machines at Yicen Precision allow for tight tolerances and complex geometries, accommodating a wide range of materials including metals and plastics. This ensures your parts meet stringent industry standards while maintaining cost-effectiveness.

We combine technology with expertise to offer CNC turning solutions that meet your exact requirements:

Our team of skilled machinists and engineers works closely with you to optimize design and production efficiency, delivering parts that fit perfectly every time.

CNC turning is vital for many industries, and Yicen Precision proudly supports sectors including automotive, aerospace, medical devices, electronics, and heavy machinery. Our precision parts often serve as critical components in assemblies requiring durability and exact fit.

At Yicen Precision, excellence isn’t optional, it’s our standard. We understand that the success of your project depends on the precision and reliability of each part we produce. That’s why we invest heavily in quality controls and maintain open communication throughout the manufacturing process.

Our customer-centric approach means we listen carefully to your needs and deliver solutions that exceed expectations on time and within budget.

Die CNC-Schnellbearbeitung von Prototypen eignet sich perfekt für die Herstellung von technischen oder Produktionsprototypen, die dem Endprodukt in Aussehen und Funktionalität sehr ähnlich sind. Bei Yicen bieten wir Ihnen sofortige Angebote und eine schnelle Lieferung, damit Sie präzise und qualitativ hochwertige CNC-gefertigte Prototypen für Ihren Bedarf erhalten.

Die CNC-Bearbeitung von Kleinserien dient oft als Brücke zwischen Prototyping und Massenproduktion für neue und aufkommende Produktionen. Mit Yicen wird dieser Prozess einfacher, effizienter und kostengünstiger, so dass Sie die Produktion schnell skalieren und gleichzeitig hohe Qualitätsstandards einhalten können.

Die CNC-Produktionsbearbeitung ist die beste Lösung für die effiziente Herstellung von tausend oder mehr Teilen. Yicen nutzt eine vielfältige Auswahl an Werkstoffen sowie Automatisierungs- und Mehrachsenkapazitäten, um Großserien mit engen Toleranzen, überragender Maßgenauigkeit, hoher Zuverlässigkeit und kurzen Durchlaufzeiten zu fertigen.

Erkunden Sie Bearbeitende Dienstleistungen Blog finden Sie Expertenwissen über CNC-Bearbeitung, Branchentrends, Fertigungstipps und Technologie-Updates - damit Sie informiert und inspiriert bleiben und in der Präzisionstechnik einen Schritt voraus sind.

Is prototyping available for CNC turning?

Absolutely, we provide quick turnaround prototyping services.

How fast can you deliver CNC turned parts?

Turnaround times vary but are generally between days to a couple of weeks depending on complexity.

How fast can you deliver CNC turned parts?

Turnaround times vary but are generally between days to a couple of weeks depending on complexity.

Do you offer secondary operations like drilling or milling?

Yes, our multi-axis machines allow integrated secondary operations.

Can you machine threaded parts?

Yes, we specialize in threading and other detailed finishing on turned parts.

What sizes of parts can you machine?

We handle small to medium-sized components with diameters ranging from a few millimeters up to several inches.