Our parts achieve tolerances as tight as ±0.1 mm, depending on the design and process.

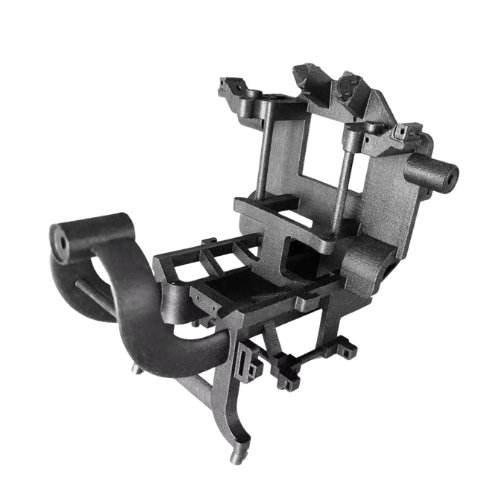

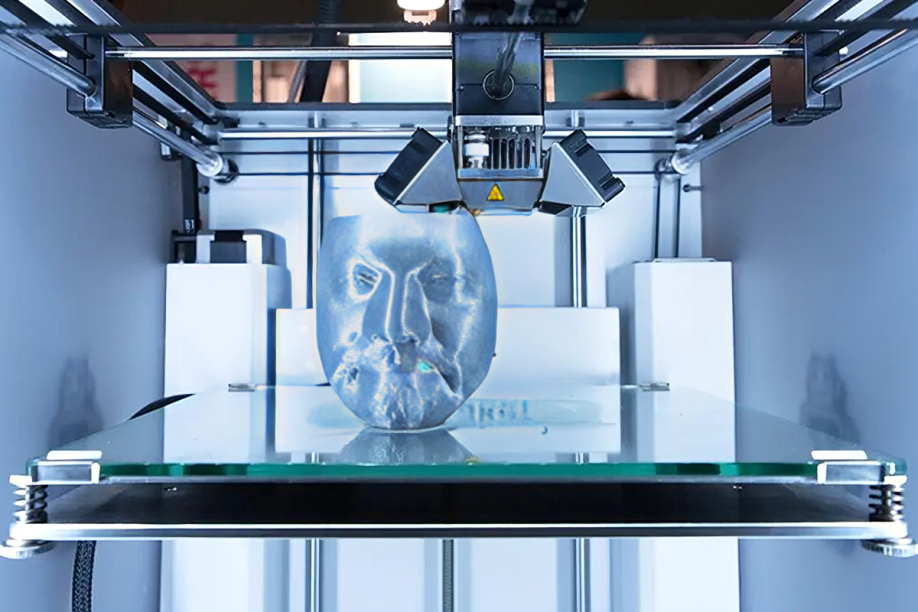

Produce durable, intricate metal components with unmatched accuracy through state-of-the-art additive manufacturing. This technology unlocks complex geometries impossible with traditional methods, ensuring both strength and fine detail. From prototypes to production-grade parts, achieve exceptional results that push the limits of innovation.

Yicen Precision’s Metal 3D Printing Service enables the production of high-strength, complex metal parts directly from digital models using advanced additive manufacturing technologies such as Direct Metal Laser Sintering (DMLS) and Metal Binder Jetting. This service is ideal for producing lightweight structures, intricate geometries, and functional components that would be difficult or impossible to create using traditional methods.

| Parameter | Spezifikation |

|---|---|

| Maximale Teilegröße | Up to 12” x 12” x 16” (300 x 300 x 400 mm), depending on printer type and material. |

| Standard-Vorlaufzeit | 1–2 weeks for printing; longer if heat treatment, machining, or surface finishing is required. |

| Allgemeine Toleranzen | ±0.010” to ±0.020” (±0.25 mm to ±0.50 mm) depending on part size, feature detail, and orientation. |

| Präzisionstoleranzen | Critical features can achieve ±0.005” (±0.127 mm) |

| Mindestgröße des Merkmals | ~0.015” (0.4 mm); varies by printer type (DMLS, SLM, EBM) and material used. |

| Surface Finish | As-printed: typically Ra 250–400. |

Our metal 3D printing solutions deliver fast production of robust, precision-engineered parts. This advanced approach allows intricate geometries, internal passages, and lightweight designs beyond the reach of conventional manufacturing. Using stainless steel, titanium, and select alloys, we meet strict industry standards perfect for both prototypes and full-scale production with exceptional strength and accuracy.

Ingenieure und führende Hersteller vertrauen auf Yicen Precision, wenn es um schnelle Iterationen und langlebige, leistungsstarke Teile geht. Ob für Prototypen oder für die Großserienproduktion, unsere umfangreiche Materialauswahl gewährleistet Präzision, Festigkeit und Zuverlässigkeit für jedes CNC-Bearbeitungsprojekt.

Aluminum AlSi10Mg

Stainless Steel 17-4

Stainless Steel 316/L

At Yicen Precision, we provide specialized surface finishing services to enhance the functionality, aesthetics, and dimensional accuracy of your metal-printed components.

Applies controlled heating and cooling cycles to relieve internal stresses, improve mechanical properties, and stabilize dimensional accuracy after printing.

Enhances fatigue strength and surface consistency by bombarding the surface with high-velocity spherical media.

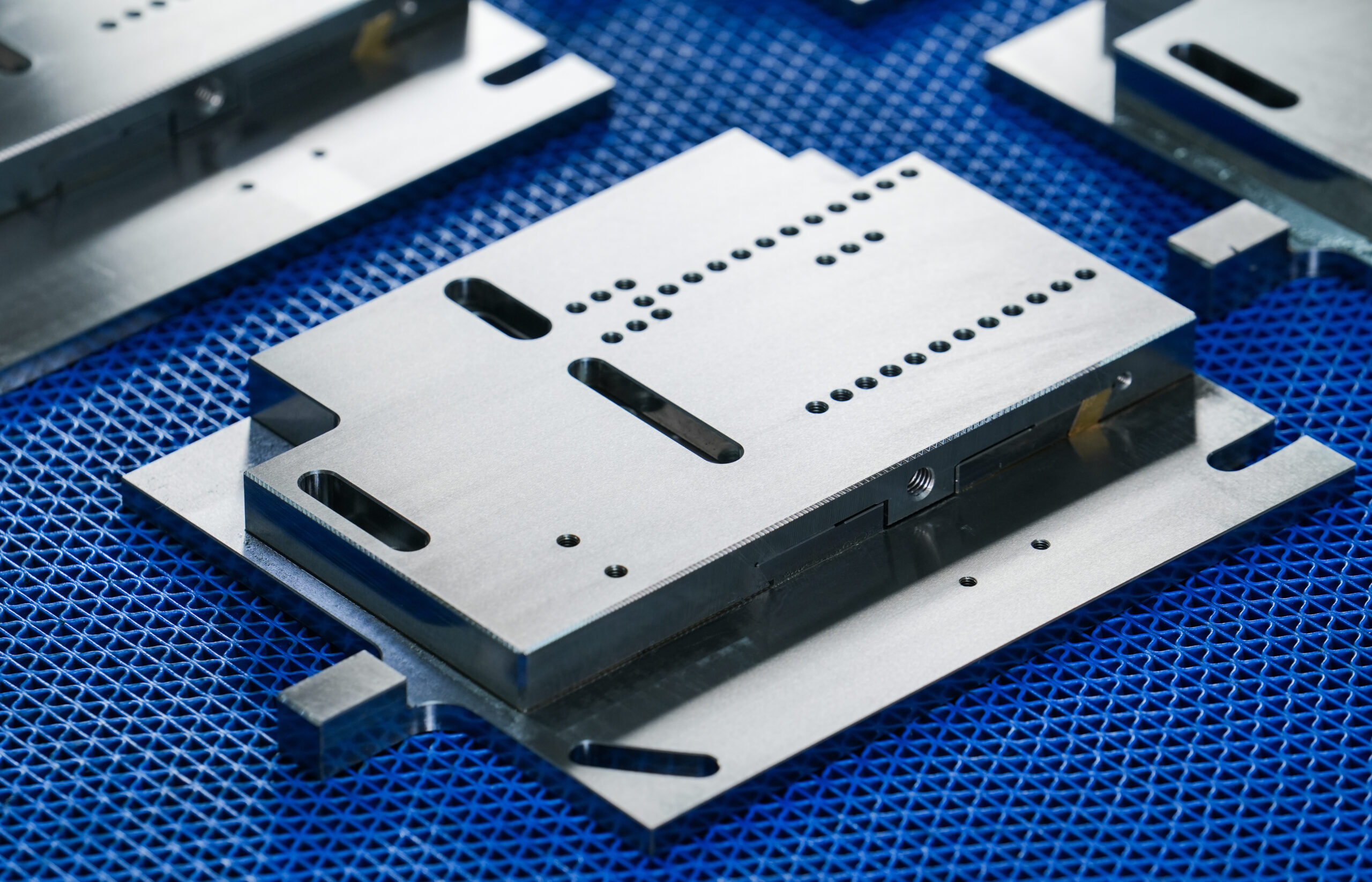

Used to refine critical surfaces, tighten tolerances, and improve dimensional precision. Ideal for functional interfaces, sealing surfaces, or high-accuracy features.

The default surface directly from the printer, with a slightly rough texture. Suitable for internal features, early prototypes, or non-cosmetic applications.

A chemical process used to smooth surfaces, remove contaminants, or selectively reduce roughness without affecting the internal material properties.

Protective coatings such as ceramic or physical vapor deposition (PVD) enhance wear resistance, reduce friction, and improve surface hardness for demanding applications.

Precise mechanical processes that refine surface finish and achieve tight dimensional tolerances. Often used on critical surfaces such as holes, bores, or sealing faces.

An electrochemical process that smooths and brightens metal surfaces, reducing roughness and improving corrosion resistance, commonly used for stainless steel components.

Wir sind darauf spezialisiert, Ihre Ideen mit beispielloser Schnelligkeit und Präzision in hochwertige, funktionale Komponenten umzusetzen. Mit fortschrittlicher Technologie und fachmännischem Können stellen wir Teile her, die selbst die komplexesten Spezifikationen erfüllen.

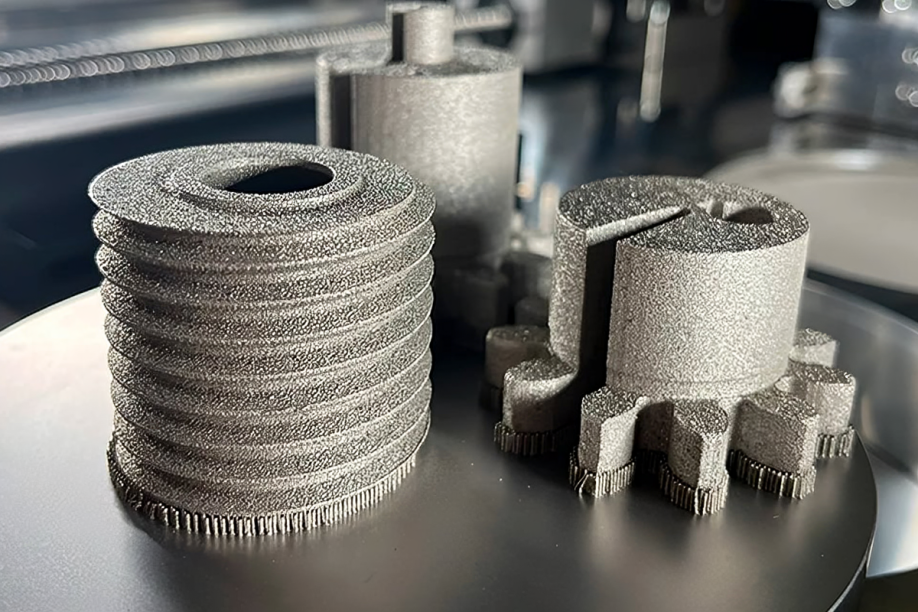

Metal 3D printing employs cutting-edge methods such as DMLS, SLM, and Binder Jetting to transform digital designs into durable, intricate metal parts with remarkable accuracy.

One of the most widely used techniques, DMLS uses a high-powered laser to selectively fuse fine layers of metal powder. Each layer is built with extreme precision, often 20–60 microns thick, resulting in dense and durable components suitable for aerospace, automotive, and medical applications.

Similar to DMLS but with complete melting of metal particles, SLM produces parts with mechanical properties equivalent or sometimes superior to forged metals. It’s ideal for structural components that require high strength and fatigue resistance.

Using an electron beam instead of a laser, EBM operates in a vacuum, reducing oxidation and making it perfect for reactive metals like titanium. This method is common in aerospace and orthopedic implants where material purity is critical.

In this process, a binding agent “prints” the part layer-by-layer using metal powder, followed by sintering in a furnace. Binder jetting is faster than most laser-based methods, making it attractive for higher-volume production.

Metal 3D printing offers unmatched design freedom, rapid production, and exceptional strength, making it a game-changer for modern manufacturing.

Traditional manufacturing often restricts geometry due to tooling constraints. Metal 3D printing eliminates these barriers, enabling internal channels, lattice structures, and complex curves in a single build design that were previously impossible.

By optimizing designs with lattice patterns, weight can be reduced by up to 60% while retaining or even improving structural integrity. This is especially valuable in aerospace and automotive sectors where every gram matters.

Metal 3D printing significantly shortens development timelines. A functional prototype that might take 6–8 weeks via traditional machining can be produced in just 7–10 days, accelerating product launches and reducing R&D costs.

Subtractive methods often waste large amounts of material. Metal additive manufacturing uses up to 90% of the material powder in the final part, reducing costs and environmental impact.

Businesses can print parts when needed, minimizing storage costs and reducing downtime from supply chain disruptions, a benefit many companies discovered during recent global logistics challenges.

Die CNC-Schnellbearbeitung von Prototypen eignet sich perfekt für die Herstellung von technischen oder Produktionsprototypen, die dem Endprodukt in Aussehen und Funktionalität sehr ähnlich sind. Bei Yicen bieten wir Ihnen sofortige Angebote und eine schnelle Lieferung, damit Sie präzise und qualitativ hochwertige CNC-gefertigte Prototypen für Ihren Bedarf erhalten.

Die CNC-Bearbeitung von Kleinserien dient oft als Brücke zwischen Prototyping und Massenproduktion für neue und aufkommende Produktionen. Mit Yicen wird dieser Prozess einfacher, effizienter und kostengünstiger, so dass Sie die Produktion schnell skalieren und gleichzeitig hohe Qualitätsstandards einhalten können.

Die CNC-Produktionsbearbeitung ist die beste Lösung für die effiziente Herstellung von tausend oder mehr Teilen. Yicen nutzt eine vielfältige Auswahl an Werkstoffen sowie Automatisierungs- und Mehrachsenkapazitäten, um Großserien mit engen Toleranzen, überragender Maßgenauigkeit, hoher Zuverlässigkeit und kurzen Durchlaufzeiten zu fertigen.

Erkunden Sie Bearbeitende Dienstleistungen Blog finden Sie Expertenwissen über CNC-Bearbeitung, Branchentrends, Fertigungstipps und Technologie-Updates - damit Sie informiert und inspiriert bleiben und in der Präzisionstechnik einen Schritt voraus sind.

How precise are the metal 3D printed parts?

Our parts achieve tolerances as tight as ±0.1 mm, depending on the design and process.

Can I use metal 3D printing for functional parts?

Yes, we produce fully functional, durable parts suitable for demanding applications.

How fast is the turnaround time?

Typical lead times range from a few days to two weeks depending on complexity.

Is post-processing available?

Yes, we offer heat treatment, CNC machining, polishing, and surface finishing.

Can metal 3D printing reduce manufacturing costs?

Absolutely, it reduces tooling and material waste, especially for low to medium volumes.