The online CNC-Bearbeitung industry hit $95.29 billion in 2024 and expects growth to $195.59 billion by 2032. This growth highlights why understanding cnc machining parts becomes crucial for anyone working with automated manufacturing equipment. Each component in a CNC system plays a specific role in creating the precision that makes these machines valuable across multiple industries.

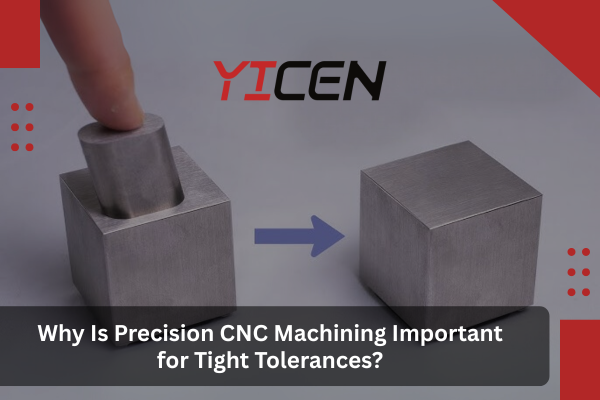

CNC machining parts combine to form systems that produce complex parts with exceptional accuracy. Standard CNC machining delivers tolerances of ±0.005 inches, while high precision setups achieve ±0.0005 inches. Such capabilities explain why businesses invest in online CNC machining service options for aerospace and medical applications where accuracy matters most.

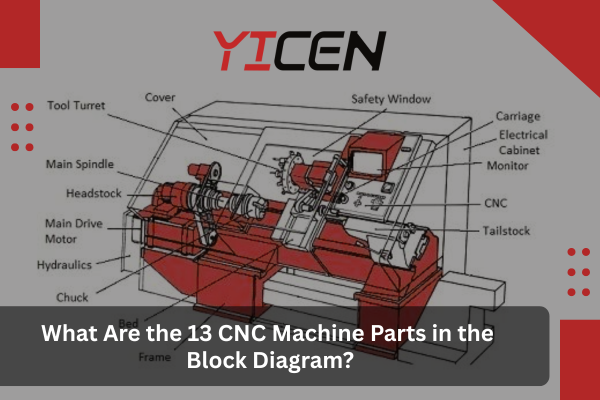

Understanding CNC Machine Parts

CNC machining parts help machine shops achieve repeatable results that manual methods cannot deliver. Asia Pacific leads with 34.6% revenue share in 2022, showing widespread adoption. These CNC machines follow G-code instructions to reduce errors and boost productivity in precision machining work.

Each part has a distinct purpose that contributes to overall precision and dependability. Well-maintained systems run around the clock with little oversight, which makes them valuable for custom CNC-Bearbeitungsdienstleistungen and rapid prototyping work.

| Component Category | Accuracy Level | Manufacturing Benefit |

| Control Systems | ±0.001 mm positioning | Automated precision manufacturing |

| Mechanical Parts | ±0.0025 mm repeatability | Consistent results for metal and plastic parts |

| Feedback Systems | Real-time monitoring | Quality control throughout production parts cycles |

Essential CNC Machine Parts and Functions

Input Device

Input devices load CNC programs into machine systems. These support keyboard entry, USB connections, and wireless data transfer. Modern devices work with STEP, IGES, and STL files from CAD software, allowing smooth integration with design workflows for custom part creation.

Machine Control Unit (MCU)

The MCU converts G-code instructions into precise machine movements. NIST studies show today’s MCUs include digital-twin models and AI features for maintenance prediction. These units manage servo motors, tool positions, and coolant systems with timing accuracy needed for precision CNC work.

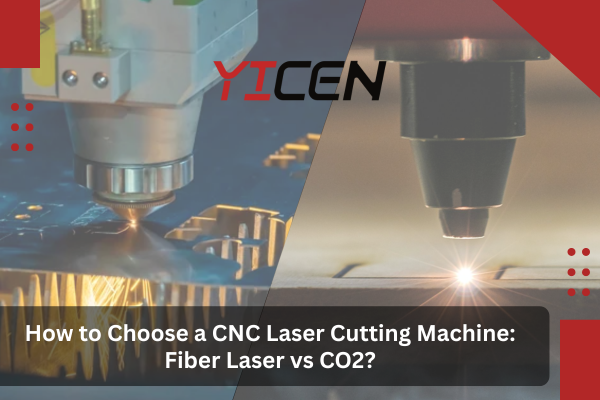

Machine Tools

Machine tools cut and shape metal and plastic materials. CNC lathe systems captured 23.4% market share in 2024. Mills use rotating cutting tools on fixed workpieces, while lathes spin workpieces against fixed tools. 5-axis CNC machines move both parts simultaneously for complex components.

Driving System

Drive systems move parts across multiple axes using servo motors, ball screws, and linear guides. Servo motors grew 9.5% CAGR thanks to better torque and energy efficiency. These systems reach micrometer accuracy levels essential for tight tolerances.

Feedback System

Feedback systems track machine performance using encoders and sensors. Closed-loop systems held 67% market share in 2024. Advanced versions include vibration and temperature sensors for maintenance prediction while ensuring accuracy for high-quality parts.

Display Unit

Display units show real-time machine status including G-code progress, coordinates, and alerts. Touch-screen interfaces make program editing easier and reduce training needs for CNC machine shop workers.

Specialized Parts for Different CNC Applications

Bed and Workholding Parts

Machine beds offer stable platforms with T-slots and mounting points for fixtures. 5-axis platforms expect 10.8% CAGR growth through 2030 because single-setup capability reduces repositioning needs for complex parts manufacturing.

Headstock Assembly

Headstock assemblies house drive systems, bearings, and gears that power chuck rotation. Current units feature advanced bearings for high-speed work and long service life with variable-speed drives for metal or plastic material optimization.

Tailstock Support System

Tailstock systems support long cylindrical workpieces to prevent bending during machining process work. Programmable units move along Z-axes automatically to fit different lengths with hydraulic or pneumatic pressure for consistent clamping on turned parts.

Tailstock Quill Mechanism

Quill mechanisms keep workpieces aligned during rotation using cone-shaped parts. Pneumatic pressure pushes quills into pre-drilled centers for stable support throughout machining process cycles while allowing efficient part removal for fast turnaround times.

| Lathe Component | Typical Accuracy | Primary Function |

| Headstock | ±0.002 mm runout | Workpiece rotation and drive |

| Tailstock | ±0.005 mm alignment | Long workpiece support |

| Chuck System | ±0.01 mm concentricity | Workpiece clamping and centering |

Control Systems and Safety Features

Footswitch and Pedal Controls

Footswitch controls handle chuck and tailstock functions while keeping hands free for workpiece handling during rapid machining work. Ergonomic designs reduce operator fatigue during long production parts runs with safety locks preventing accidental activation.

Chuck Systems and Workholding

Chuck systems hold workpieces during rotation and machining process work. Three-jaw chucks center round stock automatically while four-jaw chucks allow independent adjustment. The CNC lathe market hit $17 billion in 2024 with expected 10.4% CAGR growth for precision machining uses.

Yicen Precision CNC Machine Parts Optimization

Yicen Precision uses advanced cnc machining parts to deliver instant quote capabilities and fast turnaround prototyping with ±0.005 mm tolerance manufacturing. Their ISO 9001:2015, ISO 13485, and IATF 16949 certifications meet international quality standards for custom CNC work.

Services include CNC-Drehen for cylindrical parts, CNC milling for Luft- und Raumfahrt and medical uses, rapid prototyping for concept testing, and custom metal fixture design. Their online CNC machining service offers instant online quote features for custom metal and plastic parts production.

Maintenance and Performance

Preventive Maintenance Needs

Regular maintenance keeps cnc machining parts working properly while extending equipment life for state-of-the-art CNC systems. Scheduled work includes lubrication, calibration checks, and part inspection. Modern predictive maintenance watches performance constantly for precision CNC work.

Performance Monitoring Technology

Advanced systems track individual part performance throughout production parts cycles. Real-time data sharing allows parameter optimization while finding improvement opportunities for CNC manufacturing, keeping consistent quality while reducing machining costs.

Industry Uses and Future Trends

Market Growth and Uses

Asia Pacific leads with 55.32% market share in 2024, driven by CNC manufacturing automation. The automotive components sector holds 29% market share while medical devices show 9.9% CAGR growth through 2030. These trends show expanding applications of CNC in precision industries needing precise parts.

Technology Integration

AI integration improves CNC efficiency and accuracy while cutting machining costs. IoT sensors allow real-time monitoring and remote control for machining centers. Machine learning algorithms optimize cutting tool settings automatically, improving surface finish quality while extending tool life for metal cutting work.

Schlussfolgerung

Understanding cnc machining parts helps machine shops improve their machining process work while getting better quality results. These 13 key parts work together to create advanced CNC manufacturing systems that make complex parts with exceptional precision and consistency.

The global online CNC machining market expects to reach $195.59 billion by 2032 with 9.9% CAGR growth. This shows cnc machining parts will keep evolving to meet growing automation needs. Companies like Yicen Precision show how well-maintained systems deliver consistent quality across different manufacturing process uses including prototypes and production parts.

Technology advances will bring enhanced AI capabilities, better connectivity, and smarter monitoring systems to cnc machining parts. These improvements will deliver even greater precision while cutting machining costs, keeping CNC technology essential for competitive CNC manufacturing worldwide.

Frequently Asked Questions About CNC Machine Parts

What tolerance levels can modern CNC machine parts achieve?

Standard CNC machining tolerance reaches ±0.005 inches (0.13mm), while precision work achieves ±0.002 inches (0.051mm). Specialized operations maintain ±0.0005 inches (0.0127mm) on reamed holes when features get machined on the same part side using state-of-the-art CNC equipment.

How do CNC machine parts differ between mills and lathes?

CNC machining parts work differently based on what they need to do. Mills focus on multi-axis cutting tool abilities with complex tool changers, while lathes emphasize spinning workpiece handling with specialized chuck and tailstock systems designed for turned parts production and cylindrical metal parts.

What factors affect CNC machine parts accuracy?

Machine precision, material properties, cutting tool quality, and heat stability greatly impact achievable tolerances. Harder materials allow tighter tolerances because of better stability, while proper heat management prevents accuracy loss during long machining process work.

How does Yicen Precision ensure CNC machine parts quality?

Yicen Precision keeps multiple ISO certifications while using advanced inspection equipment including CMMs and optical measurement systems. Their quality control covers material certification, size analysis, and complete testing to verify all cnc machining parts meet specified requirements for custom CNC uses.

What maintenance is required for optimal CNC machine parts performance?

Regular lubrication, calibration checks, and part inspection keep cnc machining parts working efficiently for precision machining. Modern predictive maintenance systems watch performance constantly, allowing proactive maintenance scheduling that prevents unexpected failures while maintaining production parts quality.

References and Citations

- Massachusetts Institute of Technology. (2003). “Design and Manufacturing II – CNC Machining Laboratory Manual.” MIT OpenCourseWare. https://ocw.mit.edu/courses/2-008-design-and-manufacturing-ii-spring-2003/

- Michaloski, J., Birla, S., Weinert, G., & Yen, C. (1998). “A Framework for Component-based CNC Machines.” National Institute of Standards and Technology. https://www.nist.gov/publications/framework-component-based-cnc-machines

- National Institute of Standards and Technology. (2021). “The State of Integrated CAM/CNC Control Systems: Prior Developments and the Path Towards a Smarter CNC.” https://www.nist.gov/publications/state-integrated-camcnc-control-systems

- Hardwick, M., Proctor, F., Loffredo, D., & Venkatesh, S. (2012). “Enabling Machining Vision Using STEP-NC.” NIST Manufacturing Engineering Laboratory. https://www.nist.gov/publications/enabling-machining-vision-using-step-nc

- MIT MakerWorkshop. (2024). “CNC Machining Classes and Training Programs.” Massachusetts Institute of Technology. https://makerworkshop.mit.edu/classes/