Plastic prototypes used to take weeks. Not anymore. CNC prototype machining has changed the game completely, turning solid plastic blocks into precise functional parts in just days. The technology works so well that many companies skip traditional prototyping methods entirely.

What makes this process special? Speed meets precision. While 3D printing gives you concept models, CNC prototype machining delivers parts that actually work like the final product. You can test them, stress them, even use them in assemblies. That’s why engineers love this approach for serious prototype development.

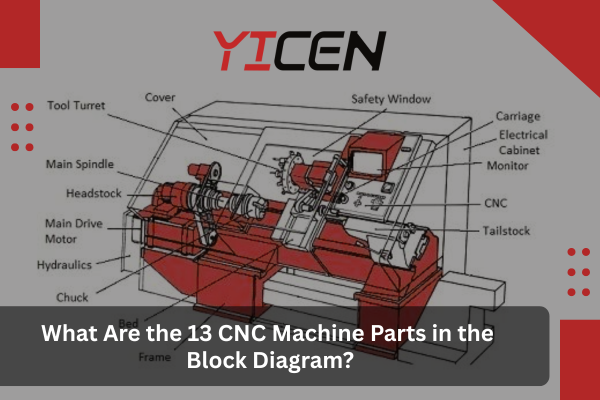

The Basics of CNC Prototype Machining for Plastics

Think of CNC prototype machining as digital sculpture. Computer-controlled cutting tools, such as those in CNC-Bearbeitungsdienstleistungen, carve away material with incredible accuracy. Modern machines hit tolerances of ±0.15mm to ±0.25mm on most plastics – tight enough for functional testing but realistic for prototype budgets, especially when using a CNC mill for precision.

The process starts with your CAD file, which is then used to program the CNC mill for precise machining. Upload it, choose your material, and the machine does the rest. No human error from manual operations. No guesswork. Just consistent, repeatable results every time.

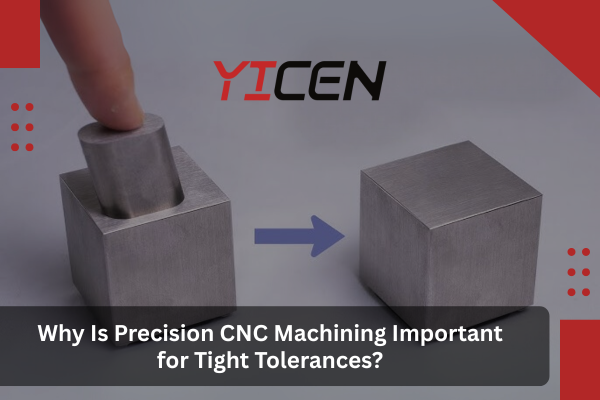

How Tight Can Tolerances Get?

Here’s where it gets interesting. While ±0.15mm works for most prototype applications, specialized setups can reach ±0.0127mm on features like reamed holes. But here’s the catch – those super-tight tolerances cost significantly more. Smart engineers save them for critical dimensions only.

ISO 2768-1-1989-m sets the standard for plastic machining tolerances. Most shops follow these guidelines unless you specify otherwise; for high-quality results, consider our CNC machined prototype services. The key is knowing when tight tolerances actually matter for your prototype’s function.

Where This Technology Really Shines

Automotive Development

Car companies live and die by prototype speed. CNC prototype machining lets them create dashboard components, trim pieces, and under-hood parts that perform like production versions. Toyota, Ford, and other major manufacturers rely on this technology for rapid iteration in the prototyping process.

The real advantage? You can crash test these prototypes to ensure they meet the necessary standards for aerospace applications. Try doing that with a 3D printed part. Yicen Präzision serves automotive clients with prototypes that survive real-world testing scenarios. Their ISO certified processes mean parts consistently meet automotive specifications.

Medical Device Prototyping

Medical prototypes face unique challenges. They need biocompatible materials, FDA-compliant processes, and often complex geometries. CNC prototype machining handles all three requirements elegantly.

Surgical instrument prototypes, diagnostic equipment housings, implantable device components – these all benefit from CNC precision. The controlled environment prevents contamination, while material traceability satisfies regulatory requirements. Medical device companies choose this process because it bridges the gap between concept and clinical testing.

Electronics and Consumer Goods

Ever wonder how phone cases get their perfect fit? CNC prototype machining creates those precise plastic enclosures that protect delicate electronics. The same process works for everything from appliance housings to sporting goods components.

Consumer product companies especially value the speed factor. Market windows are short. Getting functional prototypes quickly can mean the difference between leading the market and playing catch-up. Yicen Präzision delivers electronics prototypes in 24 hours when projects demand it.

Process Comparison Reality Check

| Method used in CNC machining services can greatly affect the final quality of the machined part. | Geschwindigkeit | Präzision | Materialien | Am besten für |

| CNC-Prototypen-Bearbeitung | 1-5 Tage | ±0.15-0.25mm | Extensive research and development are necessary to ensure high-quality outcomes in CNC machining. | Functional testing |

| 3D-Druck | 1-3 days is a typical timeframe for the delivery of 5-axis CNC machined parts. | ±0.2-0.5mm | Begrenzt | Concept models |

| Injection Molding | 4-12 weeks | ±0.05-0.1mm | Full range | Production volumes |

The table tells the story. CNC prototype machining sits in the sweet spot between speed and precision. It’s not the fastest (that’s 3D printing) or most precise for production (that’s injection molding), but it delivers the best balance for prototype development.

Material Considerations That Actually Matter

Engineering Plastics Can Be Tricky

PEEK, POM, nylon – these high-performance materials machine differently than standard plastics on a CNC mill, requiring specialized knowledge. They generate more heat, require sharper tools, and need careful parameter control. But when you need prototypes that withstand harsh environments, these materials are worth the extra effort.

The tolerance story changes with engineering plastics. Thermal sensitivity means wider tolerances (±0.15mm to ±0.25mm) compared to metals. Smart designers account for this from the start rather than fighting it later.

Standard Plastics Are More Forgiving

ABS, polycarbonate, acrylic – these common materials machine easily and consistently. They’re predictable, cost-effective, and available everywhere. For most prototype applications, they’re the logical choice.

Yicen Präzision stocks these materials in various grades, so lead times stay short. Their experience with different plastic formulations means fewer surprises and more successful prototypes.

Advanced Capabilities Worth Knowing About

Multi-Axis Magic

Five-axis CNC machines create geometries that would be impossible with traditional methods. Complex curves, undercuts, angled features – all in one setup. Less handling of machined parts means better accuracy and faster delivery.

Not every prototype needs five-axis complexity, though. Simple parts run perfectly well on three-axis machines at lower cost. The trick is matching capability to requirement.

Quality Control Systems

Professional shops use coordinate measuring machines (CMMs) to verify dimensions throughout production. Optical comparators check the surface quality of machined parts to ensure they meet industry standards in both metal and plastic. Statistical process control tracks long-term trends.

Yicen Präzision maintains ISO 9001:2015, ISO 13485, and IATF 16949 certifications. That paperwork might seem boring, but it ensures your prototypes meet specifications consistently. Documentation matters, especially for regulated industries.

The Economics Make Sense

Cost Structure Reality

CNC prototype machining costs more per piece than injection molding but eliminates tooling expenses. For prototype quantities (1-1000 pieces), the math usually favors CNC. Beyond that, injection molding economics take over.

Tight tolerances increase costs by 15-30% compared to standard specifications. Material choice affects pricing too. Engineering plastics cost more than commodity grades, but the performance difference often justifies the expense.

Material Efficiency Bonus

CNC machining wastes less material than you might think. Optimized programming nests parts efficiently, minimizing scrap. Some shops even recycle plastic chips, further reducing material costs.

When CNC Prototype Machining Makes the Most Sense

Project Requirements Assessment

Complex geometries favor CNC over 3D printing. Functional testing demands CNC over rapid prototyping methods. Tight deadlines make CNC attractive compared to injection molding. The sweet spot is functional prototypes that need to perform like production parts.

Material availability matters too. Standard plastics are usually in stock. Exotic materials might add lead time. Planning ahead in the prototyping process prevents delays.

Design Guidelines That Save Money

| Merkmal | Recommended Tolerance | Cost Impact | Notes |

| Functional fits | ±0.05-0.1mm | Hoch | Worth the precision |

| Cosmetic surfaces can be enhanced through the CNC machining process. | ±0.2-0.3mm | Niedrig | Standard tolerance fine |

| Threaded holes are often created using a CNC mill for enhanced accuracy. | Class 2B | Medium-sized projects often benefit from 5-axis CNC machining services to optimize the use of axes for complex designs. | Industry standard |

| Wall thickness | 2mm minimum | Mittel | Prevents deflection |

Smart designers specify tight tolerances only where function demands it. Everything else gets standard tolerances. This approach balances performance with cost-effectiveness.

Why Yicen Precision Stands Out

Yicen Präzision operates advanced machining centers with multi-axis capabilities and comprehensive quality systems. Their engineering team optimizes processes for each material and application. But what really sets them apart is speed without sacrificing quality.

24-hour turnaround on urgent prototypes. Standard delivery in 1-5 days. That responsiveness helps companies meet aggressive development schedules.

Beyond CNC Machining

While CNC prototype machining Machining might be their specialty, particularly with CNC mills and lathes for both metal and plastic components. Yicen Präzision offers comprehensive manufacturing services. CNC-Drehen, Laserschneiden, 3D-Druck, assembly operations – they handle complete projects from design review through finished assemblies.

This integrated approach simplifies project management. One vendor, one point of contact, faster results. Sometimes convenience matters as much as capability.

Looking Ahead

Automation Changes Everything

Industry 4.0 technologies are transforming CNC prototype machining through automated material handling and real-time monitoring. These improvements reduce labor costs while boosting quality consistency. Yicen Präzision Our company invests in these technologies to stay competitive in the mass production of high-quality components.

Predictive maintenance systems maximize equipment uptime. Remote monitoring enables faster problem resolution. These might sound like boring technical details, but they translate to better service for customers.

New Materials Keep Coming

Bio-based plastics, recycled materials, advanced composites – material science keeps advancing. CNC prototype machining adapts to these new materials as they become commercially available. The flexibility to handle new materials keeps this process relevant as sustainability requirements evolve.

Bottom Line

CNC prototype machining works because it bridges the gap between concept and reality. While 3D printing gives you models, CNC gives you parts that actually perform like production components. That’s why automotive, medical, and electronics companies rely on this process for serious prototype development.

Ready to get started? Yicen Präzision delivers functional prototypes in 1-5 days with engineering support to optimize your designs. Contact them today for instant quotes and expert guidance on your next project.

Häufig gestellte Fragen

What plastic materials work best with CNC prototype machining?

Most common plastics machine well, including ABS, polycarbonate, nylon, POM, and acrylic. Engineering plastics like PEEK work too but require more careful parameter control during the subtractive machining process. Yicen Präzision stocks popular grades and can source specialty materials when needed. Material choice for machined parts depends on your application requirements – temperature resistance, chemical compatibility, and mechanical strength, especially in aerospace applications.

How fast can CNC prototype machining deliver parts?

Standard delivery runs 1-5 business days depending on complexity and quantity of the CNC machined parts. Yicen Präzision offers 24-hour service for urgent prototypes. Lead time varies with material availability and finishing requirements. Simple parts in stock materials ship fastest.

What tolerances are realistic for plastic CNC prototypes?

Expect ±0.15mm to ±0.25mm for most plastic materials and features. Specialized processes can achieve ±0.0127mm on specific features like reamed holes. Tolerance capability depends on part geometry, material properties, and machining setup. Tighter tolerances cost more, so specify them only where function requires it.

How does CNC prototype machining compare to 3D printing?

CNC machining provides better material properties, tighter tolerances, and superior surface finish compared to 3D printing. 3D printing works well for concept models and complex internal geometries. CNC excels for functional prototypes that need production-like performance. The choice depends on your testing requirements.

What file formats do you need for CNC prototype machining?

Standard CAD formats work fine – STEP, IGES, STL, and native files from major software packages. Yicen Präzision reviews designs for manufacturability and provides feedback to optimize cost and quality. Detailed drawings help clarify design intent and tolerance requirements.

Can CNC prototype machining handle production volumes?

It bridges prototyping and production effectively for quantities up to 10,000 pieces. Yicen Präzision handles low-volume production with consistent quality across batches. This approach avoids tooling costs while maintaining reasonable per-piece pricing for smaller volumes in the CNC machining services sector.

Citations and References

- National Institute of Standards and Technology. “Manufacturing Technology Program.” NIST.gov. https://www.nist.gov/mep

- International Organization for Standardization. “ISO 2768-1:1989 General tolerances,” which are crucial for ensuring precision in CNC machined prototypes. ISO.org. https://www.iso.org/standard/7748.html

- U.S. Food and Drug Administration. “Medical Device Manufacturing Guidelines.” FDA.gov provides guidelines relevant to the machining process for medical devices.. https://www.fda.gov/medical-devices

- American Society of Mechanical Engineers. “ASME Y14.5-2018 Dimensioning and Tolerancing.” ASME.org. https://www.asme.org/codes-standards which provide essential guidelines for machining metal and plastic.

- Wikipedia Contributors. “Computer Numerical Control.” Wikipedia. https://en.wikipedia.org/wiki/Computer_numerical_control

- U.S. Department of Commerce. “Advanced Manufacturing Programs.” Manufacturing.gov. https://www.manufacturing.gov

- National Science Foundation. “Advanced Manufacturing Research.” NSF.gov. https://www.nsf.gov/eng/programs

Society of Manufacturing Engineers. “CNC Machining Fundamentals.” SME.org. https://www.sme.org