Custom CNC machining service transform digital designs into precise physical components using computer numerical control technology. This subtractive manufacturing process removes material from solid plastic and metal blocks to create exact specifications.

The CNC machining process operates through pre-programmed instructions that guide cutting tools along predetermined paths. Modern CNC shops utilize advanced CAD software integration to convert digital files directly into machined components without manual intervention.

Core CNC Machining Capabilities

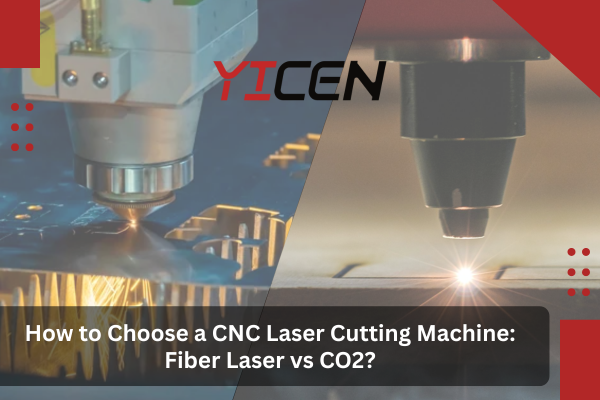

CNC Milling Operations

CNC milling uses rotating cutting tools to remove material progressively from workpieces. The process that uses 3-axis milling and 5-axis indexed milling processes enables complex surface generation in single setups.

- 3-axis milling – Standard operations for flat surfaces and simple geometries

- 5-axis milling – Advanced capabilities for complex parts requiring multiple angles

- CNC milling machine operations handle both prototyping and production volumes

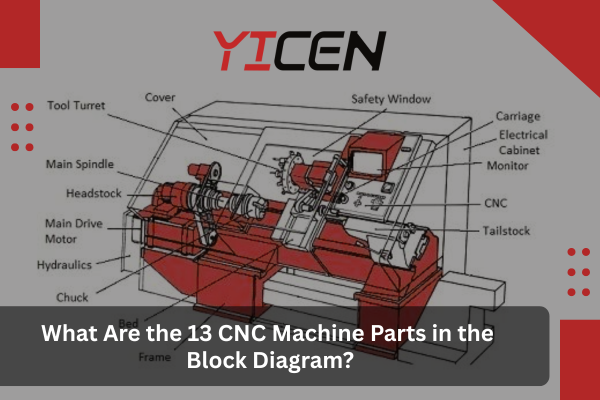

CNC Turning Services

CNC turning creates cylindrical parts by rotating workpieces against stationary cutting tools. This CNC turning with live tooling approach enables secondary operations during the turning cycle.

CNC turning services excel at producing:

- Shafts and bushings

- Threaded components

- Machine parts with cylindrical features

- Custom metal components requiring tight tolerance

| CNC Service Type | Applications typiques | Key Benefits |

| Fraisage CNC | Complex parts, prototypes | Multi-axis capabilities |

| Tournage CNC | Cylindrical parts, shafts | High-speed production |

| 5-Axis Milling | Aerospace components | Single-setup machining |

| Phenolic Machining | Electrical insulators | Specialized materials |

CNC Machining Materials and Applications

Metal Processing Capabilities

Custom CNC operations process various metal materials including aluminum alloys, stainless steel, and titanium. These CNC machining materials offer different properties for specific applications.

Aluminum alloys provide excellent machinability and corrosion resistance for aerospace and automotive applications. Custom manufacturing processes optimize cutting parameters for each alloy type.

Plastic Component Production

Precision CNC machines handle engineering plastics and composites effectively. The range of Usinage CNC capabilities includes specialized techniques for different plastic materials.

Advanced CNC systems process:

- High-performance thermoplastics

- Composite materials

- Medical-grade polymers

- Engineering plastics for electronic housings

Quality Control in Custom CNC Manufacturing

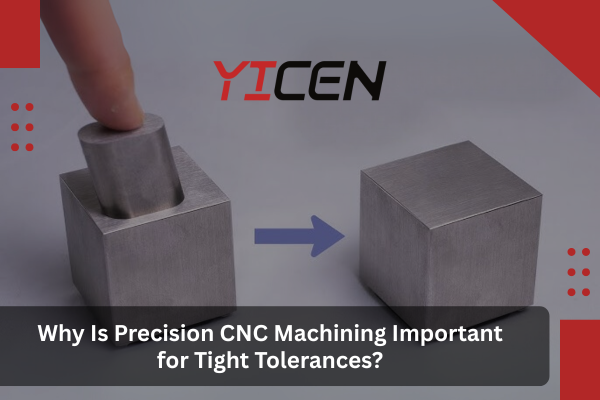

Precision Standards

Custom CNC machining service maintains strict tolerance requirements across all operations. Quality systems ensure cnc-machined parts meet dimensional specifications consistently.

Coordinate measuring machines verify dimensional accuracy while surface finish analyzers confirm cnc machining surface requirements. Multiple parts undergo inspection throughout production cycles.

Manufacturing Process Control

CNC manufacturing implements statistical process control to monitor dimensional variations. Real-time monitoring systems track machining parameters during production runs.

Advanced CNC Technologies

Multi-Axis Machining Systems

Advanced CNC equipment includes 5-axis indexed milling processes for complex geometries. These machining centers eliminate multiple setups while improving accuracy.

Simultaneous 5-axis capabilities enable:

- Complex surface machining

- Reduced setup times

- Improved dimensional consistency

- Access to difficult geometries

Automated Production Systems

Modern CNC shops integrate robotic automation for material handling and part transfer. These systems enable continuous production for high-volume requirements.

| Technology Feature | Production Impact | Quality Benefits |

| Automated Loading | 24-hour operation | Consistent handling |

| Tool Management | Reduced downtime | Optimal cutting conditions |

| Quality Inspection | Real-time monitoring | Immediate feedback |

| Process Control | Parameter optimization | Uniform results |

CNC Machining Applications Across Industries

Aerospace Component Manufacturing

Aerospace applications require exceptional precision for flight-critical components. Custom CNC machining produces turbine blades, structural parts, and landing gear assemblies.

The variety of CNC processes handles different aerospace materials including superalloys and composite structures. Advanced cnc capabilities meet stringent certification requirements.

Medical Device Production

Medical manufacturing demands biocompatible materials and sterile production environments. CNC machined parts include surgical instruments, implants, and diagnostic equipment components.

Custom cnc operations maintain FDA compliance through comprehensive process validation and documentation systems.

Automotive Component Manufacturing

Automotive production requires high-volume manufacturing for consistent quality across millions of components. CNC milling and cnc turning operations produce engine parts, transmission components, and chassis elements.

Prototyping and Production Solutions

Rapid Prototyping Services

Instant cnc prototyping enables quick design validation and functional testing. CNC machined prototypes provide accurate representation of final production parts.

Rapid prototyping and production services offer:

- Same-day prototype delivery

- Multiple material options

- Instant quote capabilities

- Design feedback and optimization

Production Part Manufacturing

Custom cnc machining service scale from prototypes to full production volumes. Manufacturing services maintain consistent quality across different batch sizes.

Les capacités de production comprennent

- Low-volume specialty runs

- High-volume automotive production

- End-use parts for multiple industries

- Complex parts requiring advanced machining

CNC Service Cost Considerations

Pricing Factors

CNC machining service cost depends on material selection, part complexity, production volume, and tolerance requirements. Online cnc machining platforms provide instant quote capabilities for cost estimation.

Key cost drivers include:

- Machining time requirements

- Material costs and availability

- Setup and programming time

- Surface finish specifications

Value Engineering Approaches

Custom part optimization reduces manufacturing costs while maintaining performance requirements. Collaboration between engineers and CNC shops identifies cost reduction opportunities.

Getting the Most from CNC Manufacturing

Choosing the Right Cutting Tools

The tools used in custom CNC machining service make a huge difference in how parts turn out. Better tools last longer and cut faster, which saves money on every job.

Most CNC shops stock different tool types:

- Carbide tools work great for steel and aluminum

- High-speed steel handles softer materials well

- Diamond coatings tackle really hard stuff

- Ceramic tools survive extreme heat

Setting Up Machine Parameters

Every CNC job needs the right speed and feed settings. The machine operator looks at the CAD file and picks settings that balance speed with quality.

Smart shops consider several things:

- What material they’re cutting

- How complex the part shape is

- How smooth the surface needs to be

- Whether expensive tools will wear out fast

Making Sure Parts Are Perfect

How CNC Shops Check Quality

Good custom CNC machining service check every part carefully. They use special measuring equipment to make sure dimensions are exactly right.

The inspection process includes:

- Measuring machines that check every dimension

- Surface testers that verify how smooth parts are

- Material tests to confirm the right grade was used

- Final checks against the original drawings

Keeping Track of Everything

Professional CNC shops keep detailed records of each job. They track which materials came from where, what settings the machines used, and how each part measured.

This paperwork helps when customers need proof their parts were made correctly. It also helps the shop learn from each job to do better next time.

Modern CNC Technology

Smart Factory Integration

Today’s CNC shops connect their machines to computer systems that track everything happening on the factory floor. This helps managers spot problems early and keep production running smoothly.

Connected systems provide:

- Better scheduling so machines stay busy

- Warnings before equipment breaks down

- Quality information that flows between departments

- Reports that show which jobs make money

What’s Coming Next

The CNC industry keeps getting better with new technology. Some machines now adjust their own settings based on how the cutting is going.

New developments include:

- Machines that learn from each cut they make

- Systems that predict when tools need changing

- Automatic quality checking during machining

- Sensors built right into the cutting tools

Conclusion

Custom CNC machining service have become essential for companies that need precise parts made quickly and reliably. Whether you need one prototype or thousands of production parts, CNC technology delivers consistent results.

The key to getting good results lies in choosing the right CNC shop. Look for companies that understand your materials, have the right equipment, and follow solid quality practices. A good partnership with a CNC service provider can speed up your product development and reduce manufacturing headaches.

CNC technology keeps advancing, making it easier to produce complex parts that were once impossible to manufacture. Companies that embrace these new capabilities often find they can bring better products to market faster than their competitors.

Questions fréquemment posées

What materials work best with custom CNC machining service?

Most CNC shops can handle aluminum, steel, stainless steel, titanium, and various plastics. Aluminum machines easily and costs less, making it popular for prototypes. Steel provides strength for structural parts. Titanium works well for aerospace applications but costs more to machine. The best material depends on what your part needs to do and your budget.

What’s the difference between CNC milling and turning?

CNC milling spins the cutting tool while the part stays still – perfect for flat surfaces, pockets, and complex shapes. CNC turning spins the part while the tool stays put, which works great for round parts like shafts, bushings, and cylinders. Many shops offer both services so they can handle any part geometry you need.

How much do custom CNC machining service typically cost?

Pricing varies widely based on your part’s complexity, the material you choose, how many parts you need, and how tight your tolerances are. Simple aluminum parts might cost $50-200 each, while complex titanium components can cost thousands. Most CNC shops offer free quotes if you send them your CAD files and specifications.

Can I use the same CNC service for prototypes and production?

Absolutely. Using the same CNC shop for both phases ensures consistency between your prototype and final parts. Many shops offer discounted prototype rates and then scale up for production volumes. This approach eliminates the risk of parts changing when you switch manufacturers.

How precise can CNC machining get?

Most CNC work holds tolerances around ±0.005 inches, which works fine for typical applications. High-end shops with climate-controlled environments and premium equipment can hit ±0.001 inches or even tighter on critical dimensions. Tighter tolerances cost more, so specify them only where your design actually needs them.