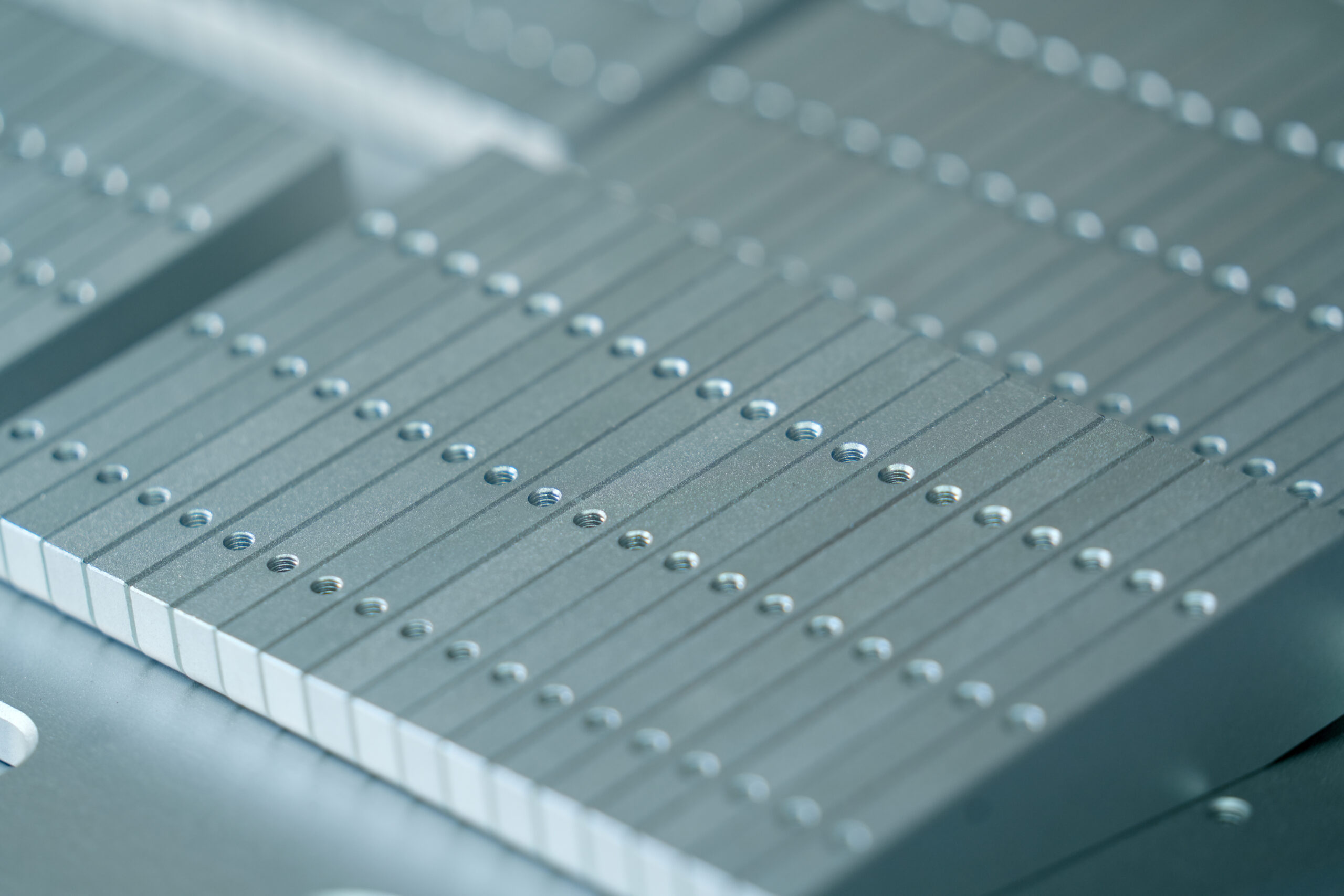

We maintain positioning tolerances within microns.

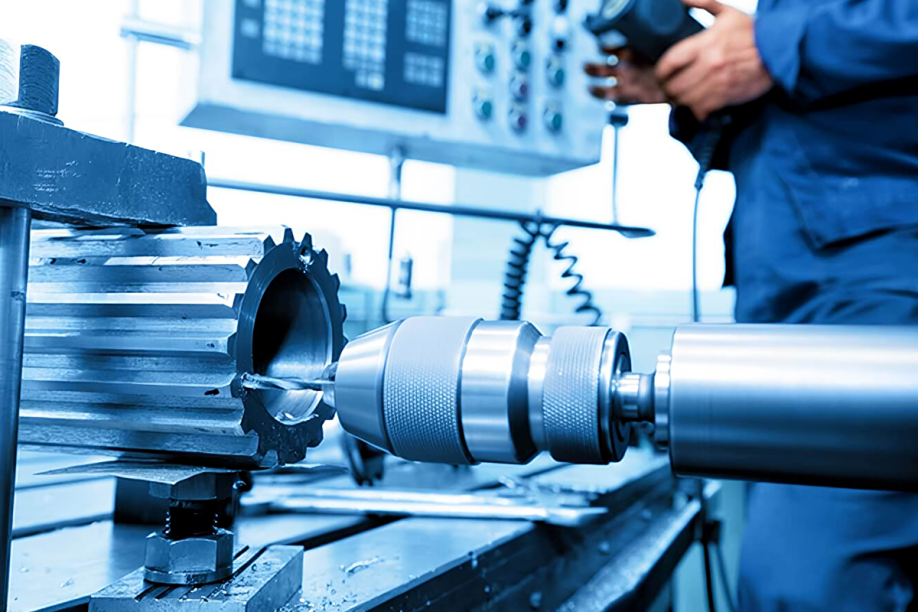

Experience precise and reliable drilling services across multiple materials and diameters. Our advanced techniques ensure consistency and high accuracy for every project, meeting the specific needs of your CNC drilling requirements. Rely on our experience to consistently provide exceptional results with every project.

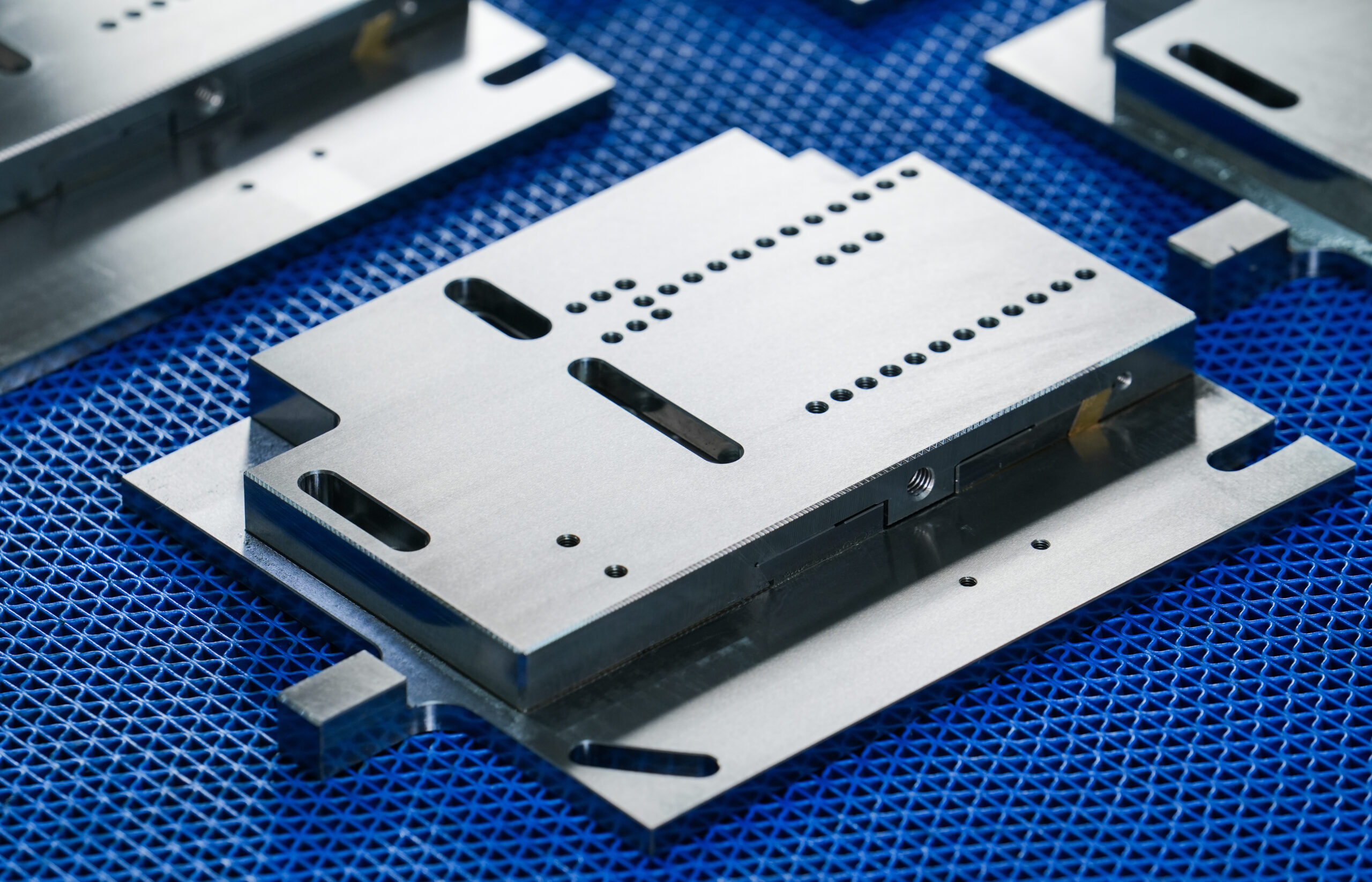

CNC Drilling is the process of producing accurate, repeatable holes in a variety of materials. With cutting-edge CNC technology, we guarantee smooth edges, accurate depths, and efficient performance, whether for prototyping or large-scale production, while maintaining consistent quality throughout every stage.

| パラメータ | 仕様 |

|---|---|

| Maximum Hole Depth | Up to 80” (2,032 mm) deep, depending on material and hole diameter. |

| Hole Diameter Range | From 0.125” to 2.0” (3.18 mm to 50.8 mm). Larger diameters available upon request. |

| Standard Lead Time | 5–10 business days, based on hole depth and material. |

| Depth-to-Diameter Ratio | Up to 100:1 with specialized tooling and coolant delivery. |

| Tolerances | Diameters held to ±0.002” (±0.051 mm). Tighter tolerances upon review. |

| Straightness | Hole straightness within 0.001” per inch (0.025 mm per 25.4 mm), depending on depth. |

Our CNC Drilling services ensure accurate hole placement and smooth finishes for intricate components. Equipped with advanced multi-axis machines, we handle a variety of hole sizes and configurations within tight tolerances. This capability guarantees dependable assembly and fastening, meeting rigorous quality standards for your parts.

Yicen Precisionは、迅速な試作と耐久性のある高性能部品を提供し、エンジニアや大手メーカーから信頼を得ています。プロトタイピングであれ、本格的な生産であれ、当社の豊富な材料セレクションは、あらゆるCNC機械加工プロジェクトの精度、強度、信頼性を保証します。

Aluminum 6061-T6

Aluminum 7075-T6

Aluminum 2024-T3

Aluminum MIC-6

Aluminum 7050-T7451

Aluminum 5083

Brass C360

Brass 260

C932 Bearing Bronze

C954 Aluminum Bronze

CNC drilling produces clean, accurate holes in metal, plastic, and composite parts. While drilled surfaces are generally functional, applying post-drilling finishes can improve part longevity, surface integrity, and appearance, especially for components exposed to wear, moisture, or public view.

The default finish with visible tool marks and potential minor burrs at entry or exit points. Ideal for internal features or when aesthetics are not a concern

Type II: Enhances corrosion resistance and provides aesthetic color options. Common for aluminum parts.

Type III (Hard Anodizing): Offers a thicker, more durable finish with superior wear resistance.

A mechanical or manual process that removes sharp edges or residual material left around drilled holes.

Applies a thin zinc coating to drilled metal parts for excellent corrosion protection. Common in hardware, automotive, and industrial applications where moisture resistance is critical.

A chemical treatment for stainless steel parts that removes contaminants and enhances corrosion resistance, making it ideal for drilled components used in harsh environments.

Ideal for stainless steel parts. This electrochemical process smooths drilled surfaces, removes burrs, and enhances corrosion resistance while achieving a bright, clean finish.

Provides a uniform, durable outer layer that protects against corrosion and wear. Available in a wide variety of colors. Best for metal parts with exposed surfaces.

Need a specific surface treatment for drilled components? Submit an RFQ and our team will help you select or develop the best finish for your application.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

CNC drilling is a cornerstone technology in modern manufacturing, enabling engineers and manufacturers to create highly accurate holes in various materials. Let’s explore the technologies behind CNC drilling:

Multi-axis CNC machines are the heart of modern drilling technology. These machines use multiple axes (typically 3, 4, or 5) to maneuver the drill bit precisely. This added flexibility allows for complex hole patterns, variable hole depths, and the creation of holes in parts with intricate shapes. The precision these machines offer ensures holes are drilled exactly where they are needed, to the tightest tolerances.

Before a drill hits a material, the part design undergoes a detailed process using CAD software. Engineers input the specific dimensions and hole patterns required for the project. The design is then translated into machine instructions via CAM software, ensuring that the CNC machine follows the exact plan. This integration eliminates human error and ensures every drilled hole is uniform across all parts, even in high-volume production.

The drill bits used in CNC drilling are often made of high-quality, wear-resistant materials like carbide or cobalt. These drill bits are designed to penetrate a diverse range of materials, including metal, plastic, composites, and ceramics. Specialized coatings, such as titanium nitride (TiN), are also used to increase the lifespan of the bits, enhancing performance and reducing the need for frequent replacements.

CNC drilling machines often feature Automated Tool Changers, which automatically switch between different tools during the drilling process. This allows for multiple drilling operations, like countersinking or tapping, to be performed in a single cycle without human intervention, reducing downtime and increasing overall efficiency.

High-speed spindles enable CNC drilling machines to operate at faster speeds without sacrificing precision. This technology significantly boosts production rates, especially in industries where quick turnaround times are crucial. It also improves the surface finish of drilled holes, making them smoother and cleaner.

CNC drilling services enhance production capabilities, offering exceptional reliability and precision to meet the demands of even the most complex projects.

CNC drilling offers exceptional precision, with tolerances as tight as 0.001 inches (0.025mm). Precision is essential in sectors like aerospace and electronics, where even minor discrepancies can result in significant failures. CNC drilling machines consistently produce holes that meet the most demanding specifications, ensuring that parts fit perfectly during assembly.

One of the most significant advantages of CNC drilling is the speed at which it operates. CNC machines can drill hundreds or even thousands of parts in a fraction of the time it would take using manual drilling methods. High-speed spindles and automated processes allow CNC drilling to maintain consistent quality without the need for frequent machine adjustments.

As CNC drilling machines can have a higher initial cost compared to traditional methods, they become cost-effective over time, particularly in high-volume production. The ability to rapidly produce large quantities of parts with minimal downtime makes CNC drilling a preferred choice for manufacturers looking to streamline their operations.

CNC drilling is a safer alternative to manual drilling. The automated nature of CNC machines reduces human involvement, minimizing the chances of operator error and potential injuries. Safety features such as automatic shutoffs and machine guards further reduce the risk during operation.

Many CNC drilling machines are equipped to handle post-drilling operations such as countersinking, tapping, and deburring. These integrated processes help reduce the need for secondary operations, further improving efficiency and quality.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

How precise are your drilled holes?

We maintain positioning tolerances within microns.

Do you offer prototype drilling services?

Yes, we provide fast prototypes as well as production runs.

What is the maximum hole diameter you can drill?

We drill holes from very small diameters up to several inches.

Can you drill angled or tapered holes?

Yes, multi-axis CNC drilling machines handle complex hole angles.

What materials can you drill?

Steel, aluminum, plastics, composites, and more.