No, we accommodate both small prototype runs and large production batches.

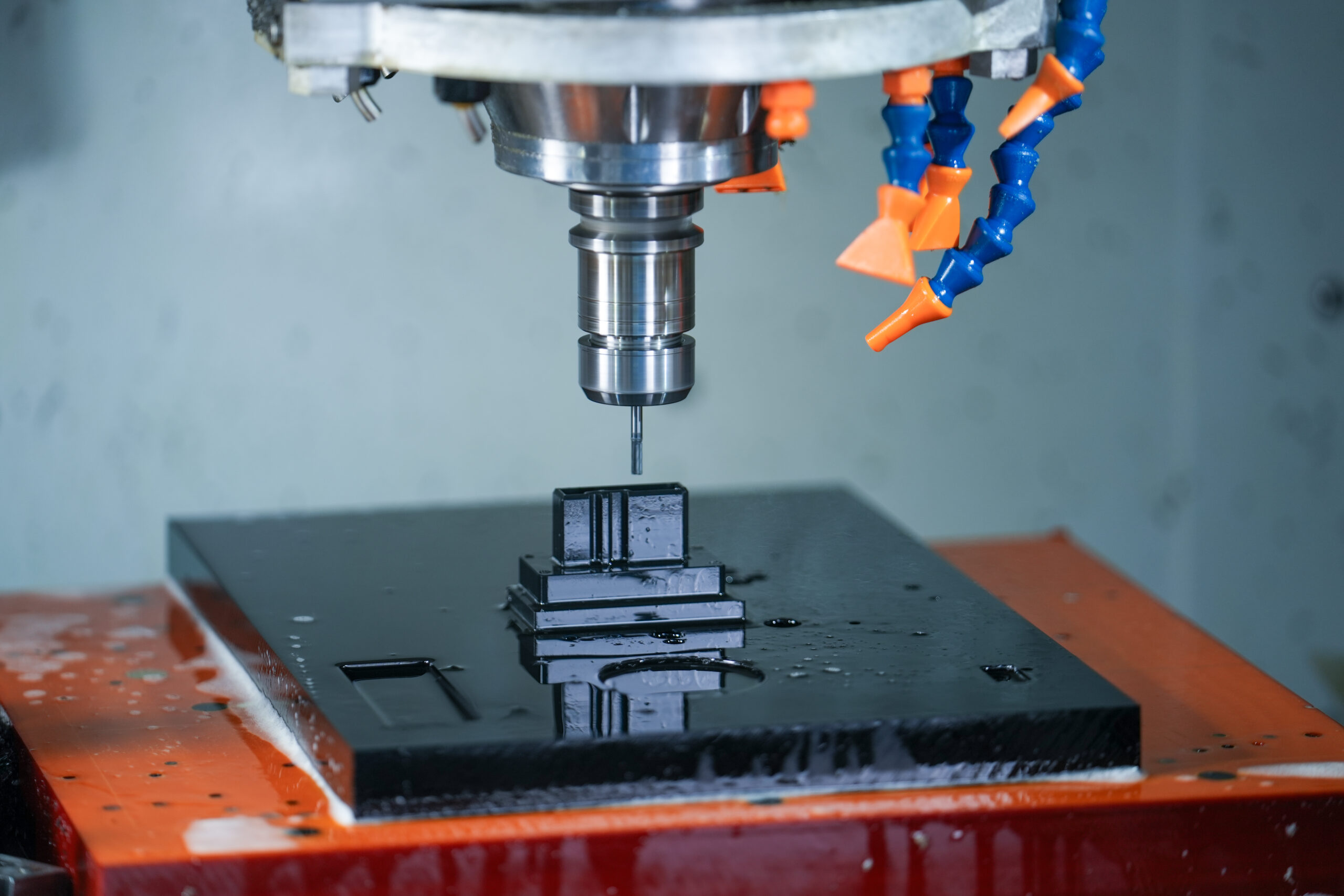

Receive top-tier CNC machining solutions tailored to your specific requirements. From quick-turn prototypes to large-volume production runs, our advanced milling and turning processes guarantee precise tolerances, swift delivery, and superior surface quality with every order.

Our CNC machining solutions are engineered to provide accurate, high-performance manufacturing support across demanding sectors such as semiconductors and more. Services include CNC milling, turning, surface grinding, wire EDM, and custom prototyping using advanced multi-axis equipment. We excel in crafting precision metal and plastic parts with tight tolerances, repeatable accuracy, and quick delivery. These scalable, cost-effective processes help streamline your product development and production cycles.

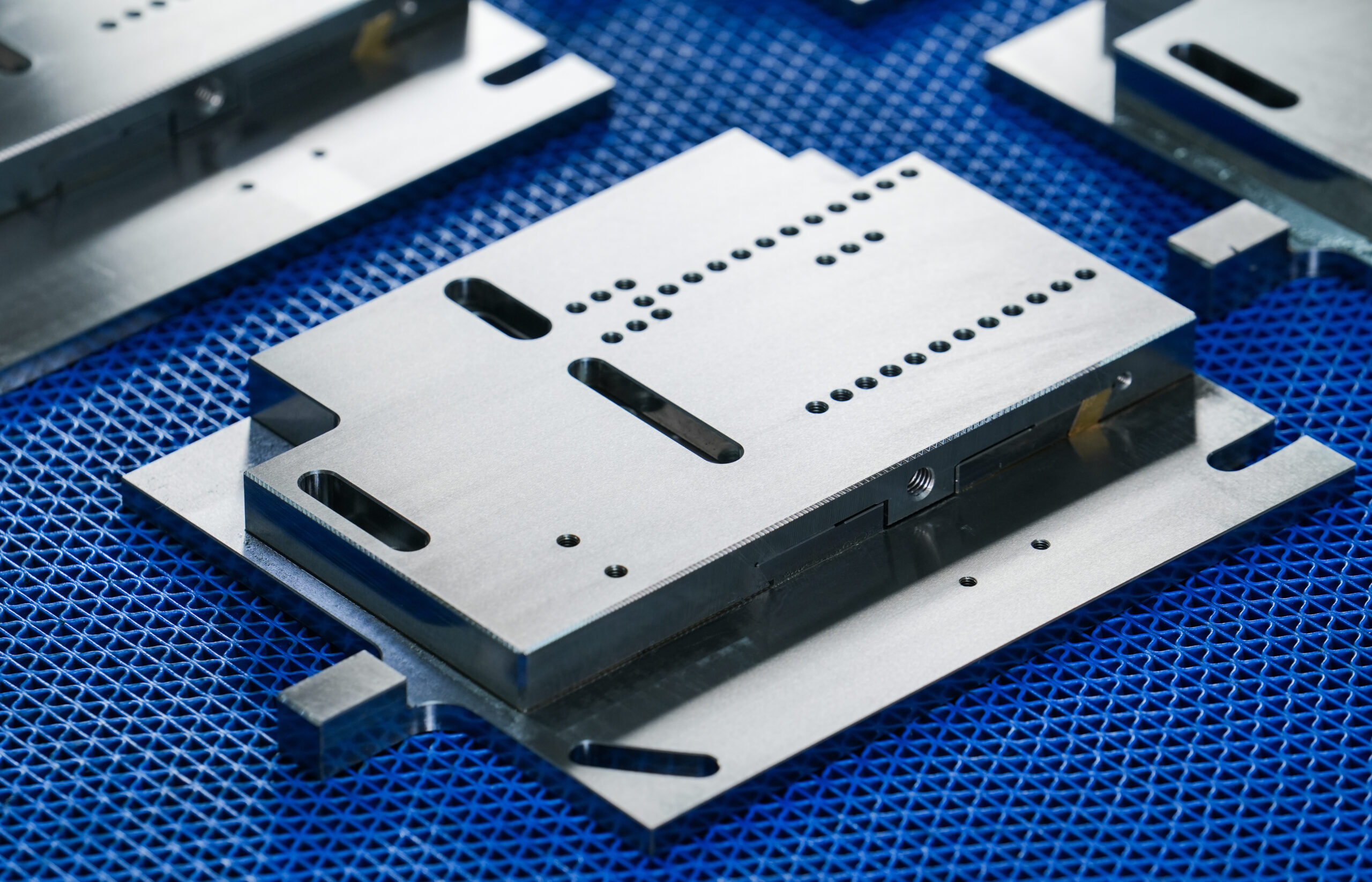

We provide CNC machining services that guarantee tight tolerances and exceptional accuracy—so every part meets the highest quality standards. The following table outlines the typical tolerance ranges, ensuring consistency, accuracy, and reliability in every custom machining project we complete.

| パラメータ | 仕様 |

|---|---|

| General Dimensional Tolerances | ±0.005” (±0.127 mm) for metals ±0.010” (±0.254 mm) for plastics In line with ISO 2768-mK unless otherwise specified |

| Tight Tolerances | Down to ±0.001” (±0.025 mm) available upon request, with detailed 2D drawings and GD&T specifications |

| Minimum Feature Size | ~0.020” (0.50 mm), depends on part geometry, tool diameter, and material |

| Hole Diameter Tolerance | ±0.002” (±0.05 mm) typical; tighter tolerances with boring or reaming |

| Flatness/Parallelism | ≤ 0.002” per 6” (≤ 0.05 mm per 150 mm), varies by material and fixture setup |

| Thread Tolerances | Standard metric and imperial threads per ISO/ASME; custom or fine threads available on request |

| Angular Tolerance | ±0.5° typical |

| Surface Finish (Standard) | Ra 3.2 μm (125 μin) as-machined; improved finishes available via polishing, bead blasting, anodizing, etc. |

Yicen Precision provides fully customized CNC machining solutions designed to meet your specific design and demands. Whether it’s a one-off prototype or a high-volume production run, our skilled team and cutting-edge equipment deliver precise results with exceptional attention to detail. Capable of handling intricate geometries and tight tolerances, our flexible approach ensures components align seamlessly with your application needs, boosting both performance and production efficiency.

| Radii | In CNC machining, sharp internal corners on a workpiece will naturally form rounded corners (radii). The depth must not exceed 12 times the diameter of the drill. For end mills, the depth must not exceed 10 times the diameter of the tool. |

| Threads and Tapped Holes | Diameter Φ 1.5-5 mm, depth: 3 times the diameter. Diameter Φ 5 mm or larger, depth: 4-6 times the diameter. Yicen Precision can produce threads of any specification and size as required by the customer. |

| Undercuts | Square profiles, full radius, dovetail profiles. |

| Text | CNC Milling: Minimum width of 0.5 mm and depth of 0.1 mm. CNC Turning: Yicen Precision can use laser marking to create standard text for CNC turned parts. Yicen Precision can create standard text via CNC engraving or laser engraving as per customer requirements. |

| Aluminium Alloy | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| 6061 | Versatile and commonly used for structural applications. | Anodizing, Powder Coating, Polishing | Construction, Aerospace, Automotive |

| 7075 | High strength, ideal for aerospace and military applications. | Anodizing, Powder Coating, Polishing | Aerospace, Military, High-Strength Components |

| 2024 | Known for its high strength and excellent fatigue resistance. | Anodizing, Cladding, Painting | Aerospace, Military, Structural Components |

| 5052 | Good corrosion resistance and formability, used in marine and automotive applications. | Anodizing, Painting, Polishing | Marine, Automotive, Sheet Metal Work |

| 5083 | Exceptional performance in extreme environments, particularly marine applications. | Anodizing, Painting, Polishing | Marine, Chemical, Industrial |

| 6082 | Excellent extrudability, used for architectural and engineering applications. | Anodizing, Powder Coating, Polishing | Architecture, Engineering, Window Frames |

| 7050 | High strength and stress corrosion resistance, often used in aerospace. | Anodizing, Cladding, Painting | Aerospace, High-Stress Components |

| 1100 | Commercially pure aluminum, excellent corrosion resistance and workability. | Anodizing, Painting, Polishing | Chemical Equipment, Food Processing, Heat Exchangers |

| Brass Alloy | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| C260 | Cartridge brass, excellent for cold working. | Plating, Polishing, Lacquering | Ammunition, Heat Exchangers, Plumbing |

| C360 | Free machining brass, used for precision parts. | Plating, Polishing, Lacquering | Precision Machined Parts, Fasteners, Plumbing |

| C353 | High leaded brass, high strength, used in plumbing. | Plating, Polishing, Lacquering | Plumbing, Fasteners, Valve Components |

| C385 | Architectural bronze, applications for its decorative appeal. | Plating, Polishing, Lacquering | Architectural Trim, Ornamental Hardware, Plumbing |

| C272 | Yellow brass, excellent corrosion resistance, used in electrical components. | Plating, Polishing, Lacquering | Electrical Components, Fasteners, Plumbing |

| Copper Alloy | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| C101 | Oxygen-free, high conductivity, used in electrical applications. | Plating, Polishing, Lacquering | Electrical Conductors, Switches, Terminals |

| C110 | Electrolytic tough pitch, highly conductive, used in electrical and plumbing. | Plating, Polishing, Lacquering | Electrical Wiring, Plumbing, Busbars |

| C122 | Phosphorus-deoxidized, used in heat exchangers and radiators. | Plating, Polishing, Lacquering | Heat Exchangers, Radiators, Plumbing |

| C172 | Beryllium copper, high strength, used in aerospace and oil drilling. | Plating, Polishing, Lacquering | Aerospace, Oil Drilling, Springs |

| C194 | High conductivity, used in automotive and electrical applications. | Plating, Polishing, Lacquering | Automotive Connectors, Electrical Connectors, Springs |

| C210 | Low brass, good ductility and strength, used in fasteners and hardware. | Plating, Polishing, Lacquering | Fasteners, Hardware, Musical Instruments |

| C220 | Commercial bronze, used in jewelry and musical instruments. | Plating, Polishing, Lacquering | Jewelry, Musical Instruments, Architectural Hardware |

| C230 | Red brass, used in architectural applications and hardware. | Plating, Polishing, Lacquering | Architectural Applications, Hardware, Plumbing |

| Grade | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| 301 | Excellent machinability, used for making automotive parts bolts, nuts, and screws. | Polishing, Passivation, Bead blasting | Used for making automotive parts, bolts, nuts, and screws. |

| 304 | Most versatile and widely used stainless steel, used in kitchen equipment tanks, piping, and tubing. | Polishing, Brushing, Passivation | Used in kitchen equipment, tanks, piping, and tubing. |

| 304L | Low carbon version of 304, used for chemical containers and transport. | Electropolishing, Passivation, Bead blasting | Used for chemical containers and transport. |

| 316 | Contains molybdenum for increased corrosion resistance, used in marine applications and chemical processing equipment. | Polishing, Passivation, Bead blasting | Used in marine applications and chemical processing equipment. |

| 316L | Low carbon version of 316, used for surgical instruments and marine hardware. | Electropolishing, Passivation, Bead blasting | Used for surgical instruments and marine hardware. |

| 410 | Martensitic grade, used for fasteners and medical instruments. | Hardening, Polishing, Passivation | Used for fasteners and medical instruments. |

| 416 | High machinability, used for gears, shafts, and valves. | Polishing, Passivation, Bead blasting | Used for gears, shafts, and valves. |

| 420 | High hardness, used for surgical instruments and cutlery. | Hardening, Polishing, Passivation | Used for surgical instruments and cutlery. |

| 430 | Ferritic grade, used for automotive trim and dishwashers. | Polishing, Brushing, Passivation | Used for automotive trim and dishwashers. |

| Steel Alloy | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| 4140 | Chromium-molybdenum steel with high toughness and good fatigue strength. | Heat Treating, Anodizing, Powder Coating | Gears, Shafts, High-Stress Components |

| 4340 | Nickel-chromium-molybdenum steel with excellent toughness and strength. | Heat Treating, Anodizing, Powder Coating | Aircraft Landing Gear, Automotive Parts, Heavy Duty Shafts |

| 8620 | Nickel-chromium-molybdenum alloy steel, case hardening steel. | Carburizing, Heat Treating, Plating | Gears, Pins, Automotive Parts |

| 1018 | Low carbon steel, good weldability and machinability. | Painting, Powder Coating, Galvanizing | Structural Applications, Shafts, Spindles |

| 1045 | Medium carbon steel, high strength and impact resistance. | Heat Treating, Plating, Painting | Gears, Shafts, Machinery Parts |

| 4130 | Chromium-molybdenum alloy steel, good strength and toughness. | Heat Treating, Anodizing, Powder Coating | Aircraft Components, Bicycle Frames, Automotive Parts |

| 1210 | Low carbon steel, good formability and weldability. | Galvanizing, Painting, Powder Coating | Automotive Parts, Machinery Components, Structural Steel |

| 17-4 PH | Precipitation-hardening stainless steel, high strength and hardness. | Heat Treating, Anodizing, Passivation | Aerospace Components, High-Strength Applications |

| チタン合金 | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| Grade 1 | Commercially pure titanium, excellent corrosion resistance and formability. | Anodizing, Polishing, Sandblasting | Chemical Processing, Marine, Medical |

| グレード2 | Commercially pure titanium, balance of strength and ductility. | Anodizing, Polishing, Sandblasting | Aerospace, Medical, Marine |

| グレード 5 (Ti-6Al-4V) | Most commonly used titanium alloy, high strength and light weight. | Anodizing, Polishing, Heat Treating | Aerospace, Medical Implants, Marine |

| Grade 9 | Titanium alloy with good weldability and cold formability. | Anodizing, Polishing, Sandblasting | Aerospace, Chemical Processing, Marine |

| Grade 23 (Ti-6Al-4V ELI) | Extra-low interstitial variant of Grade 5, high strength and toughness. | Anodizing, Polishing, Heat Treating | Medical Implants, Aerospace, Marine |

| Grade 7 | Commercially pure titanium with excellent corrosion resistance. | Anodizing, Polishing, Sandblasting | Chemical Processing, Marine, Medical |

| Grade 12 | Titanium alloy with excellent corrosion resistance and strength. | Anodizing, Polishing, Heat Treating | Chemical Processing, Marine, Aerospace |

| Plastic Material | Description | Finishing Options | アプリケーション |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene, good impact resistance and toughness. | Painting, Plating, Sanding | Automotive Parts, Consumer Products, Enclosures |

| PC | Polycarbonate, high impact resistance and transparency. | Polishing, Sandblasting, Painting | Optical Discs, Safety Equipment, Automotive Parts |

| PMMA | Polymethyl Methacrylate (Acrylic), excellent optical clarity and weather resistance. | Polishing, Sanding, Painting | Displays, Lenses, Lighting Fixtures |

| POM | Polyoxymethylene (Delrin/Acetal), high stiffness and low friction. | Machining, Sanding, Polishing | Gears, Bearings, Medical Devices |

| PEEK | Polyetheretherketone, high temperature and chemical resistance. | Machining, Sanding, Polishing | Aerospace, Medical Implants, Semiconductor Parts |

| PP | Polyphenylene , high mechanical and thermal properties. | Machining, Sanding, Polishing | Automotive, Electrical Components, Industrial Applications |

| PA66 | Polyamide (Nylon 66), high mechanical strength and rigidity. | Machining, Sanding, Polishing | Mechanical Parts, Automotive, Electrical Insulation |

| PEI | Polyetherimide (Ultem), high strength and excellent electrical properties. | Machining, Sanding, Polishing | Aerospace, Medical Devices, Electrical Components |

| SAN | Styrene Acrylonitrile, good chemical resistance and transparency. | Machining, Sanding, Polishing | Housewares, Cosmetic Containers, Automotive Parts |

| HIPE | High Impact Polystyrene, good impact resistance and machinability. | Machining, Sanding, Painting | Packaging, Consumer Products, Electrical Insulation |

| HIPD | High Impact Polypropylene, high impact resistance and low density. | Machining, Sanding, Painting | Automotive Parts, Industrial Applications, Consumer Goods |

| Fiber-Reinforced Materials | Composite materials with enhanced mechanical properties. | Machining, Sanding, Painting | Aerospace, Automotive, Sporting Goods |

CNC machining delivers high-precision, functional parts, but surface finishing is key to enhancing durability, aesthetics, and overall performance. At Yicen Machining, we provide a variety of post-machining surface treatments tailored to your specific design and application needs.

The standard finish with visible tool marks. Ideal for functional components where appearance is not a primary concern.

A fine abrasive is applied to produce a smooth, matte finish, perfect for achieving uniform texture and visual appeal.

A tough, colored coating that offers superior resistance to wear and corrosion. Available in various colors and finishes.

Generates a consistent, linear grain across metal surfaces, commonly used for decorative or semi-cosmetic applications.

Delivers a glossy, mirror-like finish that enhances visual appeal, especially for consumer-facing or display parts.

An electrochemical process that smooths and brightens metal surfaces while boosting corrosion resistance and cleanliness.

Anodizing improves corrosion resistance, surface hardness, and wear resistance while allowing for vibrant color options.

Frequently applied to CNC-machined stainless steel parts to improve corrosion resistance, particularly in medical and food-grade components.

Discover our expert CNC加工サービス, where precision meets performance. From intricate prototypes to production-ready components, we craft high-accuracy parts trusted across aerospace, automotive, electronics, and more.

Every cut, every contour—engineered with exceptional quality and care.

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

When you send us your CAD files, what happens next might surprise you. Custom CNC machining isn’t just about feeding material into a machine and hoping for the best – it’s a carefully orchestrated process that combines cutting-edge technology with decades of human expertise.

Step 1: Design Analysis and Material Selection

Our engineers spend the first 24 hours analyzing your design files, identifying potential manufacturing challenges before they become problems. We’ve learned that 73% of machining issues stem from material selection mistakes made early in the process. Whether you’re working with aluminum 6061, stainless steel 316, or engineering plastics like PEEK, we match your material properties to your application requirements. This upfront analysis typically saves our clients 15-20% in overall project costs.

Step 2: Advanced CAM Programming

Here’s where technology meets artistry. Our programmers use sophisticated CAM software to create toolpaths that maximize efficiency while maintaining precision. For complex 5-axis parts, this programming phase can take 8-12 hours, but it’s time well invested. We’re able to achieve tolerances down to ±0.0002″ consistently because every toolpath is optimized for the specific material and geometry we’re machining.

Step 3: Multi-Axis CNC Machining Technology

Our shop floor houses 3-axis, 4-axis, and 5-axis CNC machines capable of handling parts up to 40″ x 20″ x 16″. The 5-axis machines are game-changers – they can complete complex parts in a single setup that would traditionally require multiple operations. This reduces handling time by up to 60% and virtually eliminates the tolerance stack-up issues that plague multi-setup machining.

For precision turning, our CNC lathes accommodate parts from 0.125″ diameter up to 12″ diameter with live tooling capabilities. The combination of turning and milling in one setup has revolutionized how we approach complex cylindrical components.

Step 4: Quality Control Integration

Every part goes through our coordinate measuring machine (CMM) inspection process. We’re talking about measurement accuracy within 0.0001″ – that’s roughly 1/10th the thickness of a human hair. Our quality team documents every critical dimension, and we maintain statistical process control data that helps us continuously improve our processes.

Step 5: Surface Finishing and Secondary Operations

Depending on your requirements, we can achieve surface finishes from 125 Ra down to 8 Ra through various machining techniques and post-processing operations. Wire EDM capabilities allow us to create intricate profiles with 0.0001″ precision, perfect for tooling applications or complex aerospace components.

The Technology That Makes It Possible

Our investment in technology includes high-speed spindles running up to 15,000 RPM for aluminum parts and specialized tooling that extends tool life by 40% compared to standard carbide. Coolant systems maintain consistent temperatures within 2°F throughout long production runs, ensuring dimensional stability.

The result? Custom CNC machining services that deliver components exactly as designed, typically within 5-10 business days for prototypes and 2-3 weeks for production quantities. When precision matters, the process behind it matters even more.

CNCラピッドプロトタイプ加工は、外観と機能性の両方において、最終製品に酷似したエンジニアリングまたは生産プロトタイプを作成するのに最適です。Yicenでは、即座の見積もりと迅速な配達を提供し、お客様のニーズに合った正確で高品質のCNC機械加工プロトタイプを提供します。

少量生産のCNCマシニングは、多くの場合、新しい生産と新興の生産のためのプロトタイピングと大量生産の間のブリッジとして機能します。Yicenを使用することで、このプロセスがより簡単に、より効率的に、そしてコスト効率よくなり、高品質な基準を維持しながら迅速に生産を拡大することができます。

CNC生産加工は、1000個以上の部品を効率的に生産するための最適なソリューションです。多様な素材と自動化・多軸化機能を活用し、厳しい公差、優れた寸法精度、高い信頼性、迅速な納期で大量生産を実現します。

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

Is there a minimum order quantity?

No, we accommodate both small prototype runs and large production batches.

Is there a minimum order quantity?

No, we accommodate both small prototype runs and large production batches.

What file formats do you accept for machining?

We accept common CAD file formats like STEP, IGES, and DXF.

How do you ensure quality control?

We use precision measuring tools and in-process inspections to maintain tight tolerances.

Do you provide prototype machining?

Absolutely, rapid prototyping is one of our core strengths.

What is the typical turnaround time?

Turnaround depends on complexity but generally ranges from a few days to a couple of weeks.

Can you handle custom designs?

Yes, we specialize in custom CNC machining tailored to your exact specifications.