As-plated, it ranges from 45–60 HRC. After heat treatment, hardness can reach up to 68 HRC, comparable to hard chrome.

Electroless nickel plating offers a corrosion-resistant coating without the need for electricity to enhance surface smoothness Contact Yicen Machining today for high-performance surface protection.

| Description | General Tolerance or Standard |

|---|---|

| Surface Roughness (Ra) | 0.2 – 1.0 µm |

| Compatible Materials | Steel, aluminum, copper |

| Dimensional Tolerance Impact | ±0.005 – ±0.015 mm due to coating thickness |

| Visual Appearance | Uniform, metallic coating |

| Mechanical Properties | Enhanced wear and corrosion resistance |

| Best Applications | Aerospace, automotive, electronics |

私たちは、お客様のアイデアを比類のないスピードと精度で、高品質で機能的な部品に変換することを専門としています。高度な技術と熟練した職人技で、最も複雑な仕様を満たす部品を作り出します。

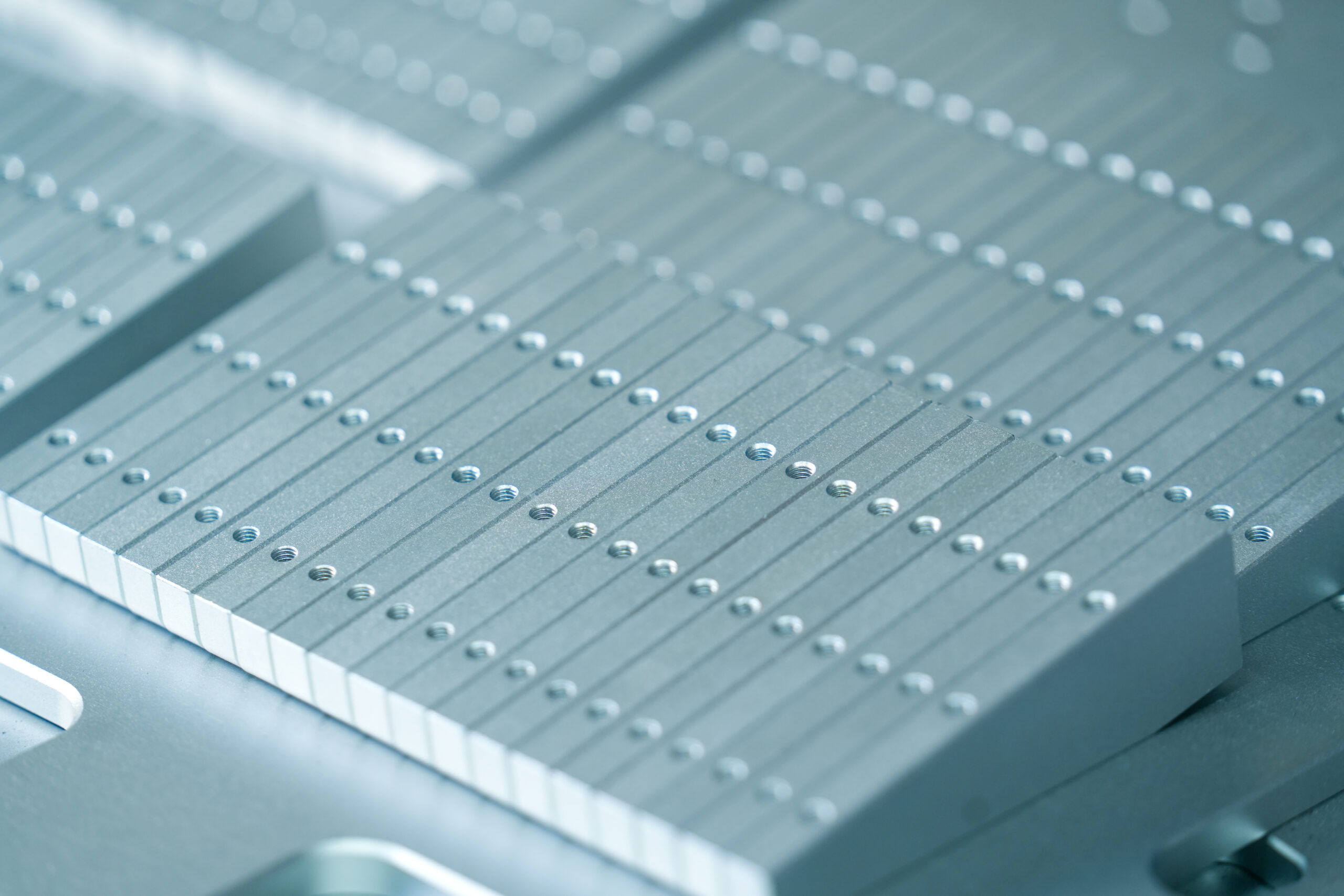

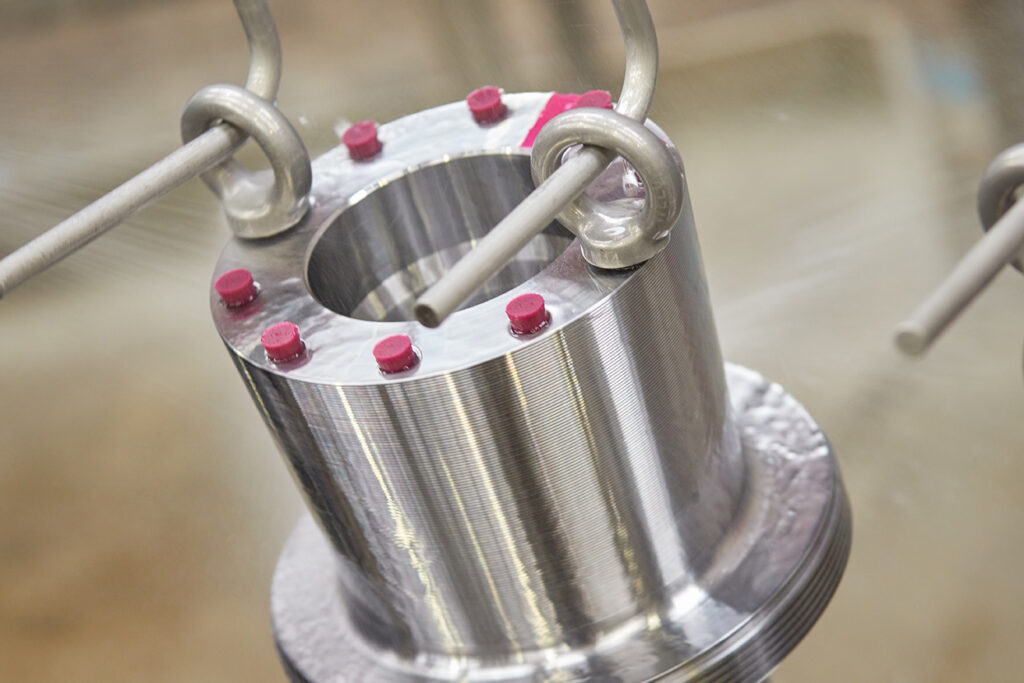

Electroless nickel plating (ENP) is a reliable surface finishing solution for demanding applications where consistent coating, corrosion protection, and improved hardness are essential. At Yicen Machining, we apply ENP to parts with complex geometries and tight tolerances ensuring a durable, uniform finish without the use of electricity.

Whether your components operate in aerospace, oil & gas, automotive, or electronics environments, our electroless nickel plating ensures maximum wear resistance, dimensional control, and part longevity.

Yicen Machining recommends ENP for high-performance parts where precision and protection are essential. Key benefits include:

Electroless nickel plating works on a variety of substrates, including:

Yicen Machining ensures material compatibility and selects the right phosphorus content based on your operational requirements.

で Yicen Machining, we offer comprehensive ENP services with expert process control, technical support, and fast lead times:

Electroless nickel plating provides superior protection and performance across industries. At Yicen Machining, we ensure your parts are finished to the highest standards ready to perform in even the most challenging environments.

Request a quote today and see how our ENP services can elevate the durability and precision of your components.

エクスペリエンス 機械加工サービス ブログでは、CNC加工、業界動向、製造のヒント、技術の最新情報など、専門家の見識をご紹介しています。

What is the hardness of the coating?

As-plated, it ranges from 45–60 HRC. After heat treatment, hardness can reach up to 68 HRC, comparable to hard chrome.

Is ENP electrically conductive?

Yes. It maintains conductivity and is used in electronics for its solderability and corrosion resistance.

Can it coat internal features like holes and threads?

Absolutely. ENP is known for its uniform coverage, including complex geometries and internal cavities.

Does ENP prevent rust?

Yes. Especially high-phosphorus ENP offers excellent corrosion resistance, even in marine or chemical exposure.

How thick is an electroless nickel coating?

Typical coating thickness ranges from 5 to 50 microns (0.0002″ to 0.002″), depending on the protection required.