Typical finishes are as smooth as Ra 0.2 microns.

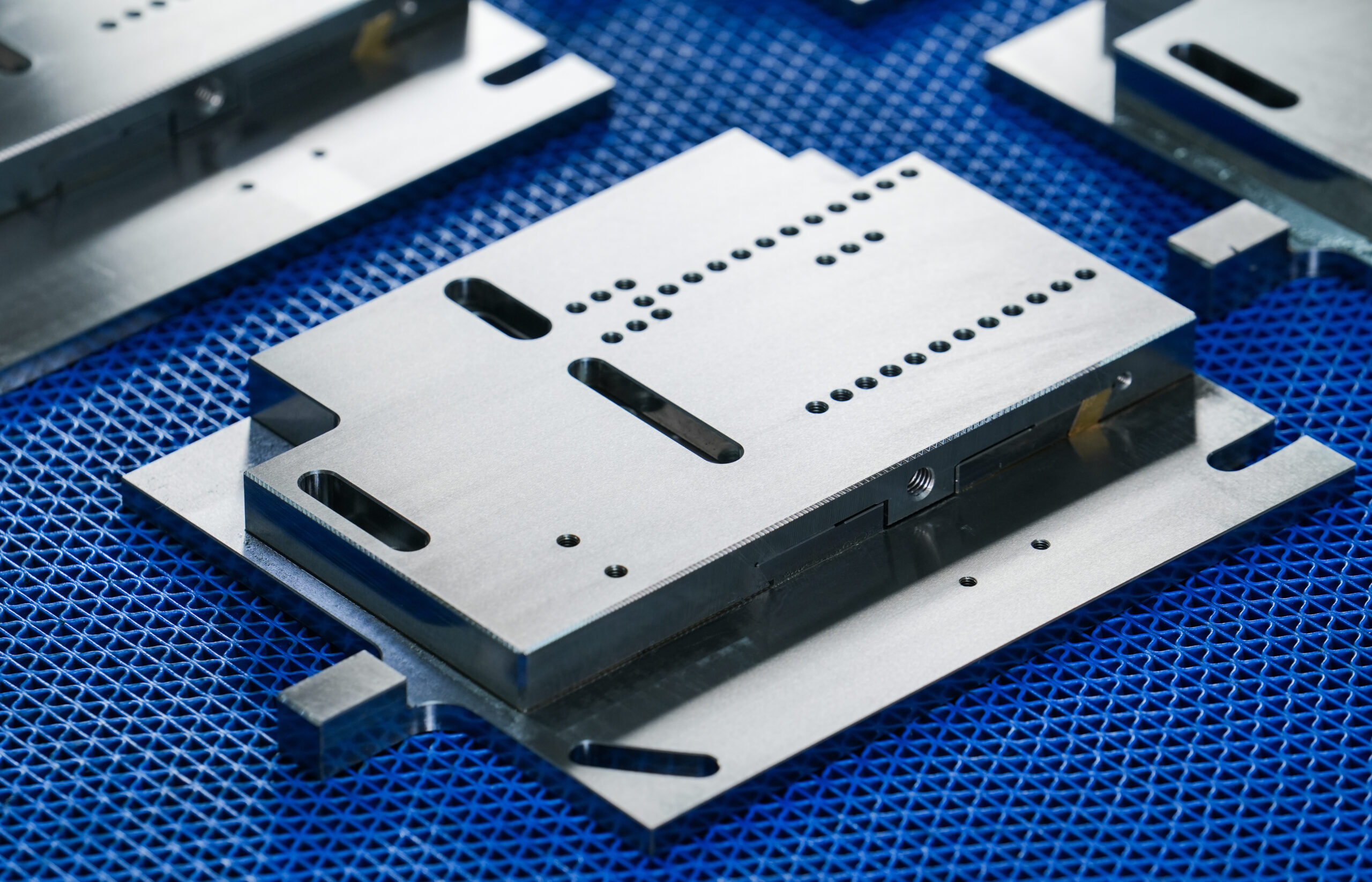

Get precise, smooth surfaces with tight thickness control, perfect for tool and die applications. Our surface grinding services ensure flawless finishes and uniformity, delivering high-quality results ideal for demanding industries. Whether for prototypes or mass production, our services provide consistency and accuracy in every part.

Surface grinding is a precise machining technique designed to create smooth, flat surfaces on both metal and non-metal parts with exceptional accuracy. Our surface grinding services achieve tight tolerances and superior surface finishes, making it ideal for components requiring exact thickness, parallelism, or flatness. This method is widely used in tooling, die making, and high-precision engineering applications.

| Parameter | Spezifikation |

|---|---|

| Abmessungstoleranz | ±0.002 mm to ±0.01 mm |

| Flatness Tolerance | ≤ 0.002 mm per 100 mm |

| Parallelism Tolerance | ≤ 0.003 mm per 100 mm |

| Oberflächengüte (Ra) | 0.1 – 0.8 µm |

| Part Size Capacity | Up to 1200 mm x 500 mm |

| Thickness Tolerance | ±0.005 mm to ±0.01 mm |

Our surface grinding services deliver precise flatness and superior surface finishes on metal components. By utilizing advanced grinding equipment, we achieve material removal with accuracy down to the micron level. This method is perfect for tooling, die components, and parts that require exact thickness. We guarantee tight tolerances and consistent quality across every project.

Ingenieure und führende Hersteller vertrauen auf Yicen Precision, wenn es um schnelle Iterationen und langlebige, leistungsstarke Teile geht. Ob für Prototypen oder für die Großserienproduktion, unsere umfangreiche Materialauswahl gewährleistet Präzision, Festigkeit und Zuverlässigkeit für jedes CNC-Bearbeitungsprojekt.

5052 H32-Aluminium

6061 T6-Aluminium

7075 T6-Aluminium

MIC6 Aluminium

Naval Brass

Free-Cutting Brass

Cartridge Brass

Gray Cast Iron

Ductile Cast Iron

Malleable Cast Iron

A36 Stahl

1018 Steel

1020 Steel

304 Edelstahl

Edelstahl 316

410 Stainless Steel

ABS

PVC

Acryl

Nylon

Klasse 2

Güteklasse 5 (Ti-6Al-4V)

At Yicen Precision, our surface grinding finishing services ensure your parts achieve precise flatness, superior surface quality, and the ideal finish for both prototyping and production needs.

The default finish from surface grinding flat, dimensionally accurate, with fine linear grind marks. Ideal for functional prototypes where flatness and parallelism are critical.

Used after grinding to reduce surface roughness and enhance reflectivity. Commonly applied when a smoother or more aesthetic finish is needed, especially on metal parts.

An ultra-precise finishing method that follows grinding to achieve extremely tight tolerances, low surface roughness, and superior flatness. Ideal for high-precision components.

A fine abrasive process used after grinding to refine surface finish and improve dimensional accuracy, especially for holes or cylindrical features.

Applies fine media to create a uniform, matte finish that reduces glare and masks minor surface imperfections on ground parts.

Removes sharp edges or burrs left from grinding, improving handling safety and preparing the part for further finishing or assembly

An electrochemical process that smooths and brightens metal surfaces after grinding, reducing roughness and enhancing corrosion resistance.

Adds protective or functional coatings such as plating, anodizing, or powder coating after grinding to improve corrosion resistance, wear performance, or aesthetics.

Wir sind darauf spezialisiert, Ihre Ideen mit beispielloser Schnelligkeit und Präzision in hochwertige, funktionale Komponenten umzusetzen. Mit fortschrittlicher Technologie und fachmännischem Können stellen wir Teile her, die selbst die komplexesten Spezifikationen erfüllen.

To achieve high levels of precision, several advanced technologies are employed. These technologies ensure consistent and efficient grinding across various materials, from metals to non-metals.

The most common technology used in surface grinding today is CNC (Computer Numerical Control) grinding. This technology allows for precise control over the grinding wheel’s position and movement, ensuring accurate and repeatable results. CNC surface grinders are equipped with automatic adjustments to compensate for wheel wear and maintain tight tolerances, often achieving precision down to 0.001 mm.

A magnetic chuck is commonly used in surface grinding to securely hold the workpiece during the grinding process. The chuck uses magnetic force to hold the part in place, ensuring it stays stable and aligned while the grinding wheel removes material. This technology improves precision and reduces the chances of movement that could affect the part’s surface finish.

Hydraulic systems are used to control the movement of the grinding table, which holds the workpiece. These systems provide smooth, consistent motion, which is crucial for maintaining a uniform surface finish. Hydraulic surface grinding is particularly effective for large or heavy components that need to be ground with precision.

A key technology in surface grinding is the wheel dressing system, which helps maintain the sharpness and geometry of the grinding wheel. This system removes any glaze or build-up on the wheel, ensuring it stays effective throughout the grinding process. Regular dressing extends the life of the grinding wheel, ensuring consistent results and reducing downtime.

Surface grinding generates significant heat due to the friction between the workpiece and the grinding wheel. To maintain the quality of the surface finish and prevent overheating, coolant systems are employed. These systems direct a stream of coolant to the grinding zone, which not only cools the surface but also helps wash away the material being ground.

Surface grinding offers numerous benefits, making it a go-to choice for industries requiring precision and quality. The key advantages include:

Surface grinding is known for its ability to achieve tight tolerances, often as precise as ±0.001 mm. This makes it ideal for applications requiring exact dimensions, such as tooling, die making, and high-precision engineering parts. This high degree of accuracy ensures that components fit together seamlessly and function as intended in their final applications.

One of the standout benefits of surface grinding is its ability to produce smooth, flat finishes. This process can provide finishes with a surface roughness value as low as Ra 0.1 micrometers, which is crucial for parts that require excellent surface quality. A smooth finish not only improves the appearance of parts but also reduces friction, which can lead to longer-lasting components.

Surface grinding can be used on a variety of materials, from metals like steel, aluminum, and stainless steel to ceramics and composite materials. The versatility of this process makes it suitable for a wide range of industries, including automotive, aerospace, medical, and manufacturing.

The precision and smoothness achieved through surface grinding enhance the overall performance and durability of the components. Whether it’s a die, mold, or precision tool, parts that undergo surface grinding tend to last longer, operate more efficiently, and require less maintenance.

Die CNC-Schnellbearbeitung von Prototypen eignet sich perfekt für die Herstellung von technischen oder Produktionsprototypen, die dem Endprodukt in Aussehen und Funktionalität sehr ähnlich sind. Bei Yicen bieten wir Ihnen sofortige Angebote und eine schnelle Lieferung, damit Sie präzise und qualitativ hochwertige CNC-gefertigte Prototypen für Ihren Bedarf erhalten.

Die CNC-Bearbeitung von Kleinserien dient oft als Brücke zwischen Prototyping und Massenproduktion für neue und aufkommende Produktionen. Mit Yicen wird dieser Prozess einfacher, effizienter und kostengünstiger, so dass Sie die Produktion schnell skalieren und gleichzeitig hohe Qualitätsstandards einhalten können.

Die CNC-Produktionsbearbeitung ist die beste Lösung für die effiziente Herstellung von tausend oder mehr Teilen. Yicen nutzt eine vielfältige Auswahl an Werkstoffen sowie Automatisierungs- und Mehrachsenkapazitäten, um Großserien mit engen Toleranzen, überragender Maßgenauigkeit, hoher Zuverlässigkeit und kurzen Durchlaufzeiten zu fertigen.

Erkunden Sie Bearbeitende Dienstleistungen Blog finden Sie Expertenwissen über CNC-Bearbeitung, Branchentrends, Fertigungstipps und Technologie-Updates - damit Sie informiert und inspiriert bleiben und in der Präzisionstechnik einen Schritt voraus sind.

What surface finish can you achieve?

Typical finishes are as smooth as Ra 0.2 microns.

How tight are your tolerances?

We maintain tolerances within ±0.001 mm.

Can you handle large or small parts?

Yes, we grind parts from tiny components to large plates.

Is surface grinding suitable for hardened materials?

Absolutely, we specialize in grinding hardened steels.

How long does a typical grinding job take?

Turnaround varies but most jobs complete within days depending on size and complexity.