Yes, we offer reverse engineering using 3D scanning and CAD modeling ideal for vintage restorations, performance upgrades, or unavailable OEM parts.

Drive performance and reliability with Yicen’s precision machining for high-demand automotive parts. Reach out with your requirements and get a fast, customized quote.

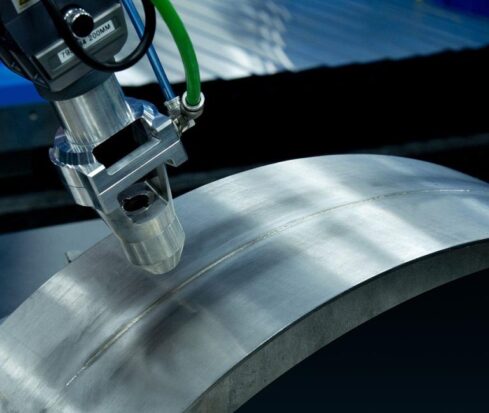

Machining services delivers high-precision, production-ready parts for the automotive industry, supporting everything from prototyping to large-scale manufacturing. We machine complex components with tight tolerances, optimized for performance, durability, and repeatability ideal for engines, drivetrains, chassis, and custom assemblies. Whether you’re building high-performance vehicles or electric systems, our advanced CNC capabilities ensure every part meets strict quality and engineering standards. Reach out today to discuss your automotive machining needs and request a free quote.

At CNC Machine Services, we deliver high-performance, custom-machined parts built to meet the precision demands of today’s automotive engineering. Whether you’re developing next-gen EV components or improving combustion engine systems, we turn your CAD files into production-ready parts with ultra-tight tolerances and full traceability.

From prototyping to high-volume production, our team machines complex geometries in aluminum, steel, stainless, titanium, and engineering plastics ensuring strength, durability, and repeatability for every part. We support OEMs, Tier 1 suppliers, and aftermarket innovators with custom CNC solutions tailored to your performance, cost, and delivery goals.

From high-performance prototypes to production-ready parts, we machine precision components that meet the demanding standards of the automotive sector.

From high-performance prototypes to production-ready parts, we machine precision components that meet the demanding standards of the automotive sector.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

At CNC Machine Services, we offer high-performance automotive materials like aluminum alloys, stainless steels, titanium, and nickel alloys. These materials are engineered for superior strength, heat resistance, and durability, ensuring optimal performance for critical automotive components. Whether it’s for engine parts, chassis, or exhaust systems, our precision machining guarantees the highest quality for every application.

At CNC Machine Services, we offer premium automotive surface finishes like anodizing, nickel plating, and powder coating to enhance strength, corrosion resistance, and appearance. Our finishes ensure your automotive parts are durable, reliable, and ready for demanding applications.

Yicen Precision provides precision CNC machining solutions across diverse industries such as aerospace, automotive, electronics, medical, and more. We deliver reliable, high-quality parts customized to meet the unique engineering requirements of each sector.

See why clients rely on Machining Services for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

The automotive industry demands more than just high output it demands accuracy, repeatability, and adaptability across a variety of materials and geometries. CNC machining checks all these boxes, enabling the precise production of components that directly impact vehicle safety, reliability, and efficiency.

At Yicen Precision, CNC isn’t just a process it’s a promise of consistency, attention to detail, and engineering excellence tailored to automotive applications.

Core Benefits of CNC for Automotive Parts:

Every vehicle is a system of interdependent parts and we machine many of the ones that matter most. Yicen Precision works across every stage of automotive development, from R&D to large-scale production, offering responsive, high-precision solutions.

Whether you’re engineering a next-gen EV or fine-tuning a performance package, off-the-shelf components often fall short. That’s why we specialize in custom parts that match your exact specs.

Common applications include:

Our combination of CNC milling, turning, Wire EDM, and surface finishing enables us to deliver automotive parts that meet both structural and cosmetic demands.

In the automotive sector, speed to validation is critical. Yicen Precision supports rapid development with quick-turn CNC prototypes, helping engineers test fit, form, and function early in the product cycle.

Prototype applications include:

With in-house DFM guidance and machining expertise, we reduce design complexity and help you iterate quickly without compromising quality.

When you’re ready to scale, Yicen Precision is ready to deliver. We offer dependable production machining backed by robust quality controls and repeatable setups. Whether it’s 250 brake brackets or 10,000 electric motor flanges, we help you meet demand on time and within spec.

Production capabilities include:

Automotive innovation doesn’t always mean starting from scratch. For legacy systems, discontinued components, or aftermarket projects, Yicen Precision offers reverse engineering services to recreate hard-to-source parts with modern precision.

Ideal for:

Using 3D scanning and CAD modeling, we rebuild accurate digital replicas and produce functional replacements often with better durability than the originals.

When the road is unforgiving, the parts must be flawless. That’s why Yicen Precision invests in strict quality assurance processes that align with automotive-grade expectations.

Our QC measures include:

We take pride in delivering parts that not only meet tolerance but exceed expectations.

From startups developing EV platforms to global OEMs refining combustion platforms, Yicen Precision is a proven partner for precision components. Here’s why we’re trusted in the fast-moving automotive world:

Short lead times, fast turnarounds, and the ability to pivot quickly especially in early-stage design or sudden production needs.

Our experienced engineers offer DFM support, CAD file optimization, and material guidance to ensure your parts are both functional and cost-effective.

Start small and scale big our production systems are built to grow with your project, whether you need 50 parts or 50,000.

We support complex projects with advanced services like 5-axis CNC, Wire EDM, deep-hole drilling, and multi-surface finishing.

The road ahead demands better parts smarter, lighter, faster, and stronger. Yicen Precision delivers the precision you need to move forward with confidence. Whether you’re reinventing transportation or refining a proven design, our CNC solutions are ready to help you drive innovation.

Let’s build the future of mobility together.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

Yes, we offer reverse engineering using 3D scanning and CAD modeling ideal for vintage restorations, performance upgrades, or unavailable OEM parts.

Absolutely. We provide scalable production from low-volume pilot runs to high-volume contracts, complete with quality control and documentation.

We offer rapid CNC prototyping, and most prototypes are delivered within 5–7 business days, depending on material and part complexity.

Yes, we machine EV-related components such as battery housings, aluminum bus bars, cooling plates, and motor mounts designed for thermal management and tight tolerances.