Yes, we can pre-assemble components, provide labeling, and kit parts for streamlined integration into your builds.

Power advanced robotics with Yicen’s precision-machined parts built for performance, durability, and tight tolerances. Send us your project specs to get a fast, tailored quote.

From high-precision gears and actuators to custom tooling and enclosures, we create performance-driven components that enhance robotic system efficiency and reliability. Our advanced machining capabilities ensure tight tolerances and superior quality, supporting everything from industrial robots to autonomous machines. With expertise in a wide range of materials, we provide robust solutions that meet the demanding standards of robotics engineering.

At CNC Machine Services, we provide precision CNC machining solutions tailored to the robotics industry, where accuracy, durability, and innovation are key. We specialize in transforming complex designs into high-performance components for robotic systems, ranging from industrial robots to advanced automation solutions.

Our capabilities support the full spectrum of robotics applications, from one-off prototypes to large-scale production runs. With a focus on tight-tolerance machining and quality control, we work with materials such as aluminum, steel, and engineered plastics to deliver custom parts that meet the highest standards of performance and reliability.

Whether you’re building robotic arms, mobile robots, or automation tools, our custom CNC solutions ensure your robotics systems operate with precision, efficiency, and longevity.

We offer precision-machined components designed to enhance the performance, reliability, and functionality of robotic systems in various applications.

We offer precision-machined components designed to enhance the performance, reliability, and functionality of robotic systems in various applications.

High-accuracy CNC manufacturing with advanced technology and unmatched efficiency.

Streamlined CNC production using state-of-the-art machinery for consistent quality.

Expert fabrication and assembly of intricate CNC components under one roof.

Fully automated CNC operations delivering fast, precise, and reliable machining.

Optimized for delivering premium-quality CNC parts with speed and precision.

End-to-end CNC manufacturing with seamless workflows and superior results.

We offer a variety of metal alloys and high-performance plastics for robotics parts, ensuring durability and reliability.

Our surface finishes, including anodizing and electroplating, improve corrosion resistance and performance in robotic applications.

Yicen Precision provides precision CNC machining solutions across diverse industries such as aerospace, automotive, electronics, medical, and more. We deliver reliable, high-quality parts customized to meet the unique engineering requirements of each sector.

See why clients rely on Machining Services for CNC machining. Our testimonials highlight satisfaction with precision, quality, on-time delivery, and dedicated support, fostering lasting partnerships across industries worldwide.

Yicen Precision has provided us with top-tier CNC machining services. Their attention to detail and efficiency is unmatched.

Fast turnaround times and precise machining. Yicen Precision always delivers quality work on time, every time.

Outstanding service and reliable machining. Yicen Precision is our go-to supplier for all CNC-related projects.

Great communication and excellent craftsmanship. Yicen Precision consistently meets our demanding specifications.

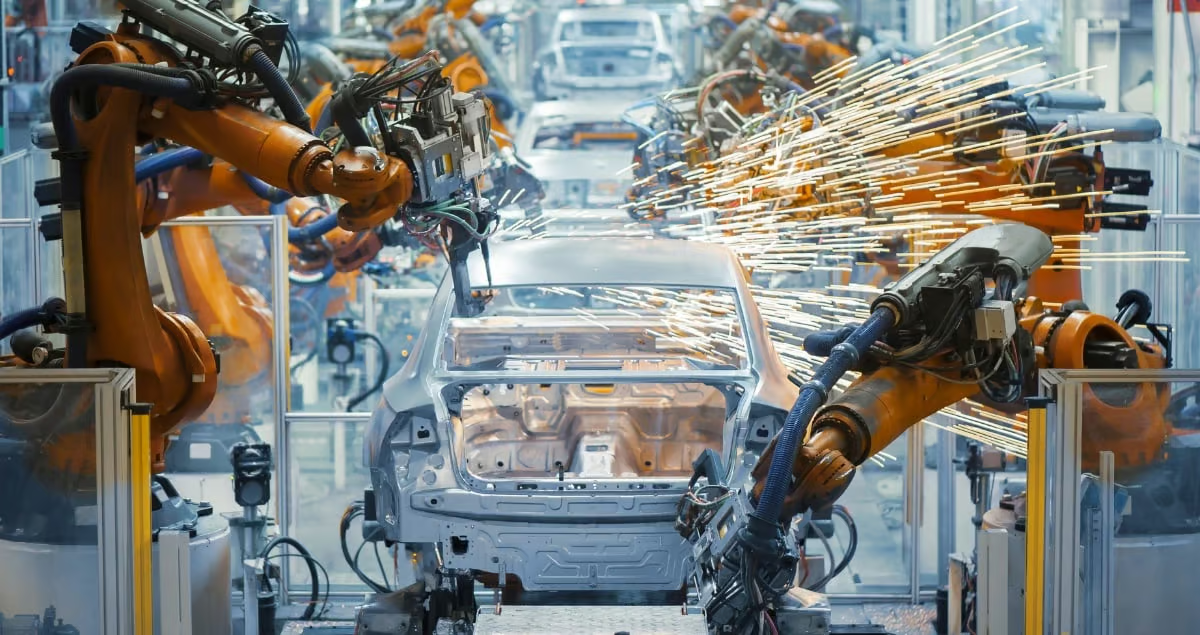

Robotics is transforming the future across industries like manufacturing, logistics, healthcare, agriculture, and defense. From robotic arms on assembly lines to autonomous delivery bots and surgical assistants, these systems rely on high-performance mechanical components to function with precision, speed, and reliability.

At Yicen Precision, we help robotics innovators bring their systems to life. With advanced CNC machining capabilities and a deep understanding of motion control, structural integrity, and miniaturized assemblies, we provide the critical components that drive robotic performance.

Robotic systems require flawless motion and repeatability. Any deviation in alignment or mechanical performance can impact positioning accuracy, system stability, or task execution. CNC machining offers the level of precision, consistency, and material versatility necessary for the robotics industry.

Yicen Precision supports robotic developers and OEMs with:

The core of any robotic arm, actuator, or mobile system is accurate motion control. We machine:

Our precision machining ensures smooth motion, reduced vibration, and long service life in high-cycle applications.

Robots must balance strength and weight. We produce:

We work with aluminum, titanium, magnesium, and carbon-fiber compatible parts for maximum strength-to-weight ratio.

Robotic perception and control require protected electronics. We manufacture:

We maintain tight tolerances for proper alignment of lenses, sensors, and electrical connectors.

Robots must interact with the world and every gripper, tool, or probe requires precision. We machine:

We support high-precision gripping and tool-handling with rigid, repeatable designs.

Whether you’re a robotics startup building your first prototype or an established OEM scaling up a product line, Yicen Precision supports every stage of your development cycle.

We deliver fully machined parts within days—ideal for testing fit, motion, and performance.

Our engineers work with your CAD models to optimize parts for precision, reliability, and simplified assembly.

Need a batch of 10 or 100 for field testing or a pilot program? We offer flexible quantities and consistent quality.

Once your robot is market-ready, we support full-scale CNC manufacturing with traceability, documentation, and reliable lead times.

Yicen Precision works with robotics companies across a broad range of sectors:

From single-joint mechanisms to fully integrated electromechanical systems we’ve machined parts for all types of robots.

When every micron matters, we deliver parts that meet your spec every time.

Explore Machining services blog for expert insights on CNC machining, industry trends, manufacturing tips, and technology updates—designed to keep you informed, inspired, and ahead in precision engineering.

Yes, we can pre-assemble components, provide labeling, and kit parts for streamlined integration into your builds.

Depending on complexity, we can deliver prototype parts in 5–7 business days with expedited service available.

Absolutely. We provide O-ring grooves, gasket seats, and sealing-ready designs, including anodized and corrosion-resistant finishes.

Yes, we machine titanium, magnesium, and high-strength aluminum alloys commonly used in mobile and aerial robotics.

Yes, we routinely machine components with tolerances down to ±0.005 mm, ideal for bearings, shafts, and motor mounts.