Choosing Between ABS or PLA Filaments

The world of 3D printing presents countless material options, yet most enthusiasts face the fundamental question: abs or pla – which works better? This decision impacts everything from ease of printing to final part performance. Understanding the difference between PLA and ABS determines project success across educational, professional, and industrial applications.

Most 3D printing enthusiasts discover that choosing the right filament requires evaluating specific project needs rather than following universal recommendations. Whether printing with polylactic acid or printing with acrylonitrile butadiene styrene, each material serves distinct purposes in FDM 3D printing applications.

PLA Filament Properties and Performance

PLA typically delivers exceptional results for beginners due to its forgiving nature and lower printing temperature requirements. This 3D printing material processes successfully between 190-220°C, making it compatible with most desktop 3D printer setups without modifications.

Key advantages of PLA filament include:

- Minimal warping during cooling cycles

- No heated bed requirements (though 50-60°C improves adhesion)

- Virtually odorless printing process

- Excellent dimensional accuracy for detailed parts

PLA is commonly used in educational environments because it produces minimal fumes during printing. The material comes from renewable corn starch sources, making it biodegradable under industrial composting conditions. However, PLA has a lower glass transition temperature around 60°C, limiting applications in high-temperature environments.

Research facilities prefer use PLA for concept validation and prototype development where moderate mechanical properties suffice. The material accepts basic post-processing techniques but offers limited chemical modification options compared to engineering thermoplastics.

ABS Material Characteristics and Applications

ABS requires more sophisticated processing conditions but delivers superior mechanical performance for functional applications. This petroleum-based thermoplastic processes at 220-260°C with heated beds maintaining 80-100°C for proper layer adhesion.

Printing ABS successfully demands:

- Enclosed printing chambers or heated environments

- Adequate ventilation systems for fume extraction

- Consistent temperature control throughout print cycles

- Higher processing expertise compared to PLA alternatives

ABS has a glass transition temperature around 105°C, enabling applications in automotive and electronic environments. The material demonstrates excellent impact resistance and flexibility, making ABS better for functional prototypes requiring durability testing.

Professional manufacturers recognize that ABS offers superior post-processing capabilities including acetone vapor smoothing for injection-molded surface finishes. ABS parts accept drilling, tapping, and welding operations that many other printer filament options cannot handle effectively.

Detailed Material Comparison Analysis

Compared to ABS, PLA demonstrates easier processing characteristics but limited temperature resistance. Whereas ABS requires complex setup procedures, it delivers exceptional mechanical properties for demanding applications.

| Property | PLA Performance | ABS Performance |

| Print Temperature | 190-220°C (lower printing) | 220-260°C (higher requirement) |

| Bed Temperature | Optional 50-60°C | Required 80-100°C |

| Tensile Strength | 50-70 MPa (stiffer than ABS) | 40-50 MPa (more flexible) |

| Impact Resistance | Low (brittle failure) | High (energy absorption) |

| Chemical Resistance | Limited solvent tolerance | Good chemical compatibility |

| Surface Finish | Excellent detail reproduction | Good with post-processing |

This comparison reveals why deciding between PLA and ABS depends entirely on specific application requirements rather than universal material superiority.

When PLA vs ABS Selection Matters

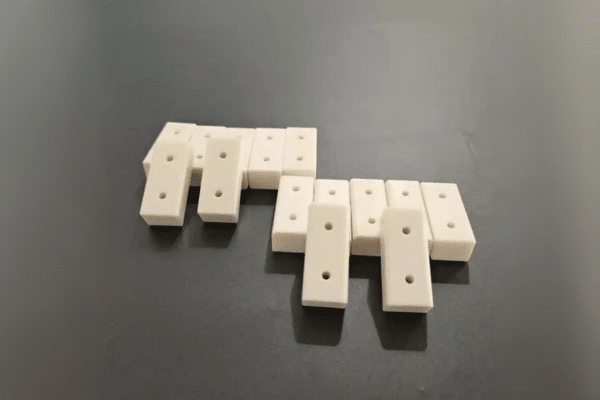

Comes to 3D printing material selection, application requirements determine optimal choices. PLA prints successfully for architectural models, educational projects, and decorative items where moderate strength suffices.

Educational applications benefit from PLA compared to other materials because:

- No ventilation requirements for classroom safety

- Lower processing temperatures reduce equipment costs

- Minimal warping prevents student frustration

- Biodegradable composition supports environmental education

However, important to note that PLA fails rapidly above 60°C ambient temperatures. Automotive dashboard applications or outdoor installations require materials with superior heat deflection properties.

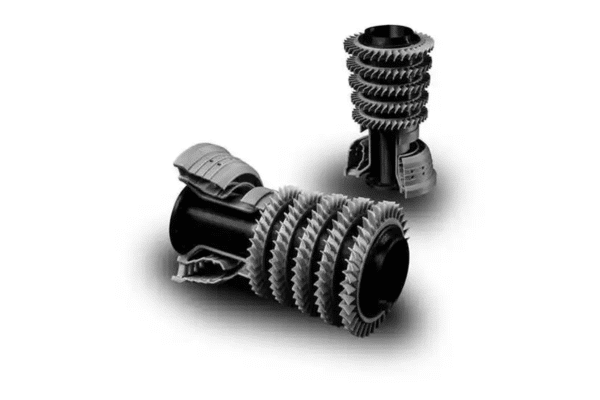

ABS vs PLA for Functional Applications

ABS is better for applications requiring mechanical durability and temperature resistance. Industries specify ABS for interior automotive components, electronic device housings, and production tooling where strength and durability become critical factors.

ABS typically performs well in applications involving:

- Temperature cycling from -40°C to 120°C

- Impact loading and mechanical stress

- Chemical exposure from cleaning solvents

- Long-term dimensional stability requirements

ABS has better layer adhesion properties under thermal stress conditions. ABS tends to maintain structural integrity where PLA would fail catastrophically. Professional CNC machining services often combine ABS 3D printing with traditional manufacturing for complex assemblies requiring precision tolerances.

Three Popular 3D printing Materials Compared

Beyond the fundamental abs or pla comparison, PETG vs both materials offers another viable option. PLA and PETG share similar processing characteristics while ABS and nylon serve high-performance applications.

PETG combines PLA’s ease of printing with ABS-like durability:

- Chemical resistance superior to PLA

- Lower processing temperatures than ABS

- Excellent transparency for optical applications

- Good impact resistance without brittleness

Understanding filament types enables better material selection across diverse project requirements. Each option serves specific niches in the development of 3D printed components and assemblies.

Processing Requirements and Safety Protocols

Printing with ABS requires comprehensive safety protocols due to styrene vapor generation during processing. OSHA guidelines specify exposure limits below 100 ppm over 8-hour periods¹. Professional facilities implement ventilation systems maintaining adequate air exchange rates.

Like ABS, other engineering thermoplastics generate potentially harmful vapors requiring proper handling procedures. Fumes during printing necessitate enclosed processing areas with exhaust systems in commercial environments.

Like PLA, most bio-based materials process safely in educational and office environments. The material generates minimal emissions during processing, enabling unrestricted use in classroom settings without special ventilation requirements.

Mechanical Properties and Testing Standards

PLA typically provides adequate strength for prototyping applications but demonstrates brittle failure characteristics under impact loading. ASTM D638 testing reveals tensile strength values between 50-70 MPa with low elongation at break².

ABS also requires standardized testing for mechanical property validation. The material shows superior impact resistance through Izod testing procedures, absorbing energy through deformation rather than catastrophic failure.

Temperature compared to PLA, ABS maintains mechanical properties at elevated temperatures where PLA rapidly loses structural integrity. This difference determines suitability for automotive and electronic applications requiring thermal stability.

Quality control protocols verify material properties through batch testing procedures including:

- Tensile strength validation per ASTM standards

- Thermal analysis confirming glass transition temperatures

- Moisture content monitoring preventing processing defects

- Dimensional accuracy verification for precision applications

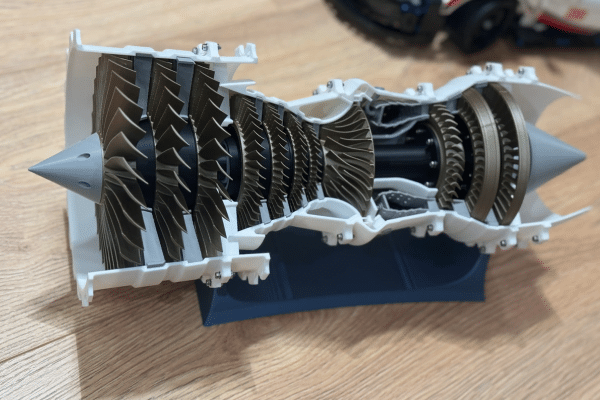

Industrial Applications and Compliance

ABS needs extensive qualification testing for regulated industries including automotive and medical device manufacturing. FDA-approved formulations enable medical device housings and pharmaceutical packaging applications³.

Choosing between ABS and alternative materials requires evaluating regulatory compliance requirements. Aerospace applications demand traceability documentation and material certification for flight-critical components.

PLA is also gaining acceptance in medical applications for biocompatible surgical guides and patient-specific models. The material’s sterilization compatibility and dimensional stability support healthcare applications requiring custom devices.

Professional 3D printing services implement comprehensive quality systems ensuring material traceability and performance validation across regulated industries.

Future Developments in Filament Printing

Makes ABS attractive for future applications includes ongoing formulation improvements incorporating fiber reinforcement and flame-retardant additives. Advanced ABS and nylon blends deliver enhanced mechanical properties while maintaining processability.

Means PLA development focuses on improved temperature resistance and mechanical performance through molecular modification and additive systems. Bio-based formulations reduce environmental impact while expanding application possibilities.

Research continues into hybrid manufacturing processes combining 3d print technology with traditional machining for components requiring precision tolerances and superior surface finishes.

Troubleshooting Common Processing Issues

Using ABS successfully requires addressing warping challenges through improved temperature control and adhesion enhancement. ABS requires consistent ambient temperatures preventing stress-induced deformation during cooling cycles.

Common solutions for ABS processing problems:

- Increase bed temperature to improve first-layer adhesion

- Implement chamber heating for temperature stability

- Use adhesion aids like ABS slurry on print surfaces

- Reduce print speeds allowing proper layer bonding

3D printing enthusiasts discover that printing with polylactic acid requires different approaches for optimal results. Temperature reduction eliminates stringing while proper cooling improves surface quality and dimensional accuracy.

Environmental Impact and Sustainability

ABS or PLA demonstrate significantly different environmental profiles throughout their lifecycle. PLA production generates approximately 68% lower carbon emissions compared to petroleum-based thermoplastics⁴.

Filament comparison regarding sustainability reveals:

- PLA: Renewable feedstock, industrial composting capability

- ABS: Petroleum-based, standard recycling compatibility

- PETG: Chemical recycling potential, lower energy processing

Professional manufacturing facilities implement waste reduction strategies optimizing support structures and material recovery systems for sustainable production practices.

Making the Final Decision

Deciding between ABS or PLA ultimately depends on balancing processing capabilities against performance requirements. Choosing the right filament requires honest evaluation of available equipment, operator experience, and application demands.

ABS is less forgiving during processing but delivers superior mechanical performance for functional applications. PLA compared to engineering materials offers excellent ease of use with moderate performance limitations.

Understanding these trade-offs enables successful material selection supporting project goals while working within equipment and skill constraints.

Conclusion

The choice between printer filament options depends entirely on specific application requirements and available processing capabilities. ABS or PLA vs other materials each serve distinct roles in modern manufacturing and prototyping applications.

Success comes from matching material capabilities with project requirements rather than seeking universal solutions. Both materials contribute valuable capabilities to the expanding world of 3D printing applications across educational, professional, and industrial sectors.

Frequently Asked Questions

Which offers easier processing when comparing ABS or PLA for beginners?

Do both ABS or PLA materials work on the same 3D printer setup?

What applications specifically require ABS over PLA for optimal performance?

How do material costs compare between these popular 3D printing materials?

Which material provides better strength and durability for functional parts?

References and Citations

- Occupational Safety and Health Administration. “Permissible Exposure Limits – Styrene.” OSHA.gov. https://www.osha.gov

- ASTM International. “Standard Test Method for Tensile Properties of Plastics.” ASTM D638-14. https://www.astm.org

- U.S. Food and Drug Administration. “Food Contact Substances and Packaging Materials.” FDA.gov. https://www.fda.gov

- Environmental Protection Agency. “Sustainable Materials Management Facts and Figures.” EPA.gov. https://www.epa.gov

- National Institute for Occupational Safety and Health. “Health Hazard Evaluation Reports.” CDC.gov. https://www.cdc.gov