Here’s something that keeps manufacturing engineers awake at night: a designer hands over beautiful CAD files with tolerances that look perfect on paper, but turn into an expensive nightmare in the real world. After fifteen years of watching this train wreck happen repeatedly, the team at Yicen Precision has learned that understanding CNC part tolerances isn’t just technical knowledge—it’s the difference between a successful product launch and a costly redesign.

Students graduate knowing how to model complex geometries but have absolutely no clue why their ±0.005mm tolerance on a plastic housing just tripled their manufacturing costs.

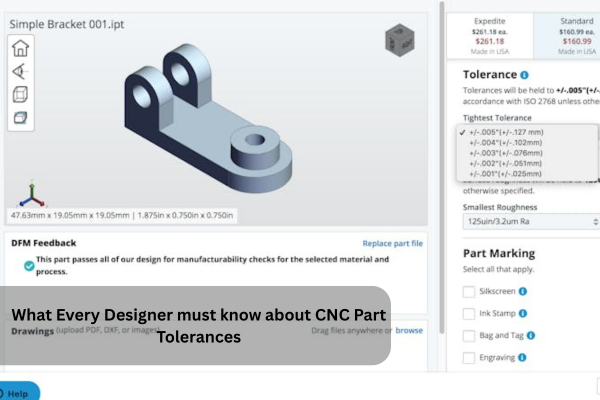

Understanding CNC Part Tolerances Before Your Budget Gets Destroyed

CNC part tolerances define how much variation is acceptable while keeping parts functional. Imagine trying to cut a 25mm diameter hole with a hand drill—sometimes it comes out 24.8mm, sometimes 25.2mm. CNC machines are infinitely more precise, but they still can’t achieve mathematical perfection.

According to NIST manufacturing standards, tolerances are critical parameters affecting product quality, cost, and performance. Here’s the practical version: tolerances are your safety net between “perfect fit” and “expensive paperweight.” When engineers specify CNC part tolerances correctly, parts assemble smoothly. Get them wrong, and even brilliant designs become manufacturing disasters.

Manufacturing veterans know this harsh reality—every tolerance decision involves three competing forces: precision requirements, cost constraints, and delivery deadlines.

Why CNC Part Tolerances Have Become Critical

Modern products aren’t getting simpler. Smartphones pack hundreds of precisely fitted components into spaces smaller than a credit card. Medical devices must perform flawlessly while meeting strict regulatory requirements. Automotive manufacturers demand consistency across millions of identical parts.

Smart CNC part tolerances management directly impacts assembly success, production costs, and market timing. MIT’s mechanical engineering researchers discovered that companies optimizing tolerance specifications during design phases reduce overall project costs by 25-40%.

The Three Types of CNC Part Tolerances That Actually Matter

Linear Tolerances Keep Things Simple

Linear tolerances control basic dimensions—length, width, height, diameter. Most machinists work with linear CNC part tolerances daily, making them straightforward to communicate and achieve.

Here’s a typical scenario: someone specifies a 20mm diameter shaft with ±0.05mm tolerance. Aluminum shafts achieve ±0.05mm tolerances easily using standard CNC turning equipment. Try the same tolerance on hardened steel, and suddenly you need different tooling, slower cutting speeds, and more expensive machines.

Angular Tolerances Where Theory Meets Reality

Angular tolerances become critical when parts must align precisely during assembly. The International Standards Organization publishes tolerance grades through ISO 2768-1, but practical machinists know these standards assume ideal conditions that rarely exist.

Standard CNC milling typically holds ±0.5 degrees without special fixturing. Achieving ±0.1 degrees requires precision workholding, calibrated equipment, and additional inspection time—all factors that significantly impact CNC part tolerances costs.

Geometric Tolerances for Advanced Applications

Geometric Dimensioning and Tolerancing (GD&T) represents the sophisticated approach to controlling part geometry. The American Society of Mechanical Engineers developed Y14.5 standards that define symbols and methods for specifying tolerances within CNC part tolerances specifications.

GD&T focuses CNC part tolerances control precisely where parts need it most, often reducing manufacturing costs while improving functional performance.

Material Properties That Make or Break CNC Part Tolerances

After machining thousands of parts across dozens of materials, Yicen Precision’s team has learned which materials cooperate with tight CNC part tolerances and which ones fight back stubbornly.

Material Tolerance Capabilities Comparison

| Material Type | Typical Range | Achievable Range | Key Challenges | Best Applications |

| Aluminum Alloys | ±0.05mm | ±0.025mm | Heat buildup on thin walls | Aerospace, electronics |

| Stainless Steel | ±0.08mm | ±0.05mm | Work hardening, tool wear | Medical, food processing |

| Carbon Steel | ±0.10mm | ±0.05mm | Varies by hardness | Automotive, industrial |

| Titanium | ±0.08mm | ±0.05mm | Poor heat dissipation | Aerospace, medical implants |

| Engineering Plastics | ±0.15mm | ±0.08mm | Temperature sensitivity | Consumer products |

Real Industries Where CNC Part Tolerances Actually Save Lives

Aerospace Manufacturing Where Failure Kills People

Aerospace applications demand the tightest CNC part tolerances because component failures can cause catastrophic accidents. The Federal Aviation Administration mandates rigorous tolerance compliance for aircraft components.

Yicen Precision regularly machines aerospace components requiring ±0.013mm CNC part tolerances. Achieving these specifications demands temperature-controlled environments, precision tooling, and extensive quality documentation.

Medical Devices Where Patient Safety Depends on Precision

Medical device manufacturing protects patient health through precise CNC part tolerances control. The Food and Drug Administration established Quality System Regulations governing every aspect of medical device production.

Hip implant components must fit perfectly to ensure proper function and patient comfort. Patient safety literally depends on manufacturing precision when dealing with CNC part tolerances.

Automotive Manufacturing Balancing Volume with Quality

Automotive manufacturers face unique challenges maintaining consistent across millions of identical parts. Modern automotive applications typically specify ±0.05mm to ±0.15mm ranges for CNC part tolerances, balancing precision requirements with manufacturing economics.

Smart CNC Part Tolerances Specification That Actually Works

Starting with Functional Requirements

Experienced designers begin with functional requirements rather than impressive-sounding precision targets. Critical questions shape effective CNC part tolerances specifications: Which dimensions actually affect part function? How do temperature changes impact assembly fit? What loads will components experience during service?

The Brutal Cost Reality

Tolerance specification dramatically affects manufacturing costs. National Science Foundation research demonstrates that halving tolerance ranges can double or triple machining costs for CNC part tolerances. This cost impact often surprises designers who assume precision always improves value.

Yicen Precision’s engineering team regularly helps designers optimize CNC part tolerances specifications, balancing precision requirements with budget realities.

Manufacturing Process Capabilities

Different CNC processes achieve varying tolerance capabilities:

CNC Process Tolerance Comparison

| Process | Typical Tolerance | Achievable Tolerance | Production Speed | Best Applications |

| CNC Milling | ±0.05mm | ±0.013mm | Moderate | Complex geometries, prototypes |

| CNC Turning | ±0.025mm | ±0.008mm | High | Cylindrical parts, high volume |

| CNC Drilling | ±0.025mm | ±0.013mm | Very High | Hole patterns, assembly features |

| Surface Grinding | ±0.013mm | ±0.005mm | Low | Critical surfaces, tight fits |

Comparing Tolerance Strategies When Precision Actually Matters

Precision strategies targeting ±0.005mm to ±0.025mm ranges command 200-400% cost premiums and extended lead times but enable aerospace, medical implants, and precision instrument applications.

Standard strategies using ±0.05mm to ±0.13mm ranges provide baseline costs and normal production timelines for general manufacturing and most mechanical parts.

Economic strategies accepting ±0.13mm to ±0.25mm ranges offer 30% cost savings and faster delivery for prototypes, housings, and non-critical components.

Overcoming Common CNC Part Tolerances Disasters

The Expensive Over-Specification Trap

Many designers specify unnecessarily tight CNC part tolerances believing tighter automatically means better. The American Society of Mechanical Engineers advocates tolerance analysis to prevent costly over-specification mistakes.

Solution: Conduct tolerance stack-up studies analyzing how individual CNC part tolerances combine to affect assembly function. Often, loosening non-critical tolerances enables tightening truly important ones within identical budgets.

Tool Wear Destroying Tolerance Consistency

Extended production runs gradually degrade tolerance capability as cutting tools wear progressively. Sharp tools cut precisely; worn tools create oversized features and poor surface finishes that compromise CNC part tolerances.

Yicen Precision implements proactive tool management protocols, replacing cutting tools before wear affects consistency.

Temperature Changes Killing Dimensional Accuracy

Thermal expansion affects both workpieces and machine tools during machining operations. A single degree Celsius temperature change alters dimensions by 0.01mm per meter in steel components, directly impacting achievement.

Climate-controlled manufacturing environments help maintain consistent CNC part tolerances regardless of weather conditions.

Advanced Quality Control for CNC Part Tolerances

Modern Measurement Technology

Today’s tolerance verification employs sophisticated equipment for measuring accurately. Coordinate Measuring Machines (CMM) provide ±0.002mm measurement accuracy for complex geometries while generating comprehensive inspection reports documenting CNC part tolerances compliance.

Optical comparators enable non-contact measurement for delicate parts where physical contact might damage surfaces. Surface roughness testers verify surface finish specifications affecting both function and appearance.

Yicen Precision’s measurement capabilities include advanced inspection equipment providing complete quality documentation, including First Article Inspection reports and material certifications supporting verification.

Statistical Process Control for Consistent Results

Modern manufacturing facilities implement Statistical Process Control monitoring CNC part tolerances achievement continuously throughout production runs. NIST provides comprehensive guidelines for manufacturing quality management systems.

SPC transforms manufacturing from reactive problem-solving to predictive problem-prevention when managing tolerances.

Integrating CNC Part Tolerances with Modern Manufacturing

Rapid Prototyping Considerations

Here’s what nobody tells you about prototypes: the CNC part tolerances you can achieve during prototyping often have little resemblance to what’s possible in production. Prototype shops use different machines, different setups, and frankly, different levels of care than high-volume production facilities.

Smart designers treat prototyping as a tolerance reality check. Build a few parts, measure everything, see what actually matters for function. You’ll be surprised how many “critical” tolerances turn out to be completely unnecessary once you see the real thing working.

The Prototype-to-Production Nightmare

This change causes more project failures than bad coffee does to productivity.You build beautiful prototypes with hand-tweaked tolerances, then try to scale up and discover your production facility can’t hit those numbers consistently without charging you a fortune.

Yicen Precision’s low-volume CNC machining services help bridge this gap. Start with realistic production tolerances from day one instead of discovering problems when it’s too late to fix them without major redesign headaches.

What Really Matters for CNC Part Tolerances Success

After watching hundreds of projects succeed and fail, here’s what actually determines success with CNC part tolerances: understanding that perfect is the enemy of good enough.

Most designers set tolerances too tight because they’re worried about things going wrong. But here’s the thing – loose tolerances that work reliably beat tight tolerances that cause production nightmares every single time.

Yicen Precision’s CNC machining services work with designers to find that sweet spot between “good enough to work” and “expensive enough to hurt.” The goal isn’t perfection – it’s consistent, cost-effective manufacturing that keeps everyone sane.

The best CNC part tolerances specification happens when designers and machinists actually talk to each other instead of throwing drawings over the wall and hoping for the best.

Where This Information Comes From:

Most of this knowledge comes from hard-won experience in machine shops and engineering departments. NIST sets the official standards that everyone references.

MIT’s mechanical engineering department does solid research on tolerance optimization that actually applies to real manufacturing.

ISO 2768-1 sets the international standards for how much variation is allowed in measurements.

ASME Y14.5 explains how to show dimensional accuracy and tolerances in drawings—it might seem a bit dry, but it’s important to know.

The FAA and FDA don’t mess around with tolerance requirements in their respective industries, and their regulations shape how everyone thinks about critical applications.

Need help figuring out realistic tolerances for your project? Yicen Precision’s engineering team has seen it all and can help you avoid the common pitfalls that trip up most designers.