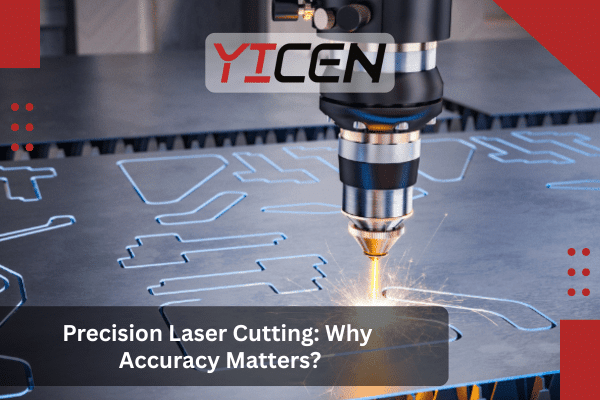

Manufacturing companies face pressure to deliver parts that fit perfectly. Precision laser cutting has become essential for achieving tight tolerances modern production demands. Medical device components must fit within 0.001 inches. Aerospace parts need exact specifications. Laser cutting delivers results other methods can’t match.

People often ask about laser cutting accuracy. Shop owners want to know what tolerances they can achieve. Engineers need reliable specifications for their designs. This technology offers solutions that traditional cutting methods simply cannot provide.

What Is Laser Cutting and How It Works

Laser cutting melts material using an incredibly hot, focused beam. The laser reaches over 10,000 degrees Celsius. The cutting head moves along paths programmed from CAD files. No physical tool touches the material during cutting.

The process includes these parts:

- A laser source creating the beam

- Mirrors and lenses focusing energy

- A cutting head moving automatically

- Gas blowing away melted material

No tool wear occurs. No blade dulling happens. Results stay consistent from the first part to the thousandth.

How Accurate Is Precision Laser Cutting

Most shops hold tolerances between ±0.005 and ±0.010 inches on metals. Plastics and thin materials achieve ±0.001 to ±0.005 inches. High-end machines push these numbers tighter.

| Material | Typical Range | Best Results |

| Steel | ±0.1 to ±0.3 mm | ±0.05 mm |

| Aluminum | ±0.15 to ±0.4 mm | ±0.08 mm |

| Plastics | ±0.05 to ±0.2 mm | ±0.025 mm |

Cut width often measures narrower than human hair – sometimes just 0.004 inches wide. Plasma cutting achieves ±0.020 inches. Precision laser cutting dominates when accuracy counts.

What Affects Cutting Accuracy

Material makes a huge difference. Stainless steel cuts clean and holds tight tolerances. Aluminum reflects laser light, making precise cutting trickier. Copper conducts heat so well that clean edges require skill.

Thickness plays a major role. Thin materials cut like butter with amazing precision. Thick materials need more power and slower speeds. This affects precision laser cutting accuracy.

Machine condition matters equally:

- Clean lenses keep beams focused tight

- Proper calibration ensures accurate head movement

- Stable power prevents cut quality variations

- Good maintenance keeps everything running smooth

Shop environment affects results too. Temperature swings make machine parts expand and contract. Vibration from nearby equipment throws off precision. Smart shops control these factors.

How Tolerances Influence Cutting Accuracy

Tolerances define what’s acceptable and what isn’t. ISO 2768 sets general standards most shops follow unless customers specify tighter requirements. ISO 9013 covers laser cutting for materials from 0.5mm to 40mm thick.

Reality check: tighter tolerances cost more. Parts needing ±0.001 inches take more time, better equipment, and skilled operators compared to ±0.010 inches.

Industries drive these requirements:

- Aerospace demands ultra-tight tolerances for safety

- Medical devices need precision for proper function

- Automotive parts must fit assemblies perfectly

- Electronics require exact dimensions for circuit boards

Getting tolerances right from the start saves money and headaches later.

How Material Choice Impacts Accuracy

Different materials behave differently under laser beams. Metals generally cut predictably. Each type has quirks though.

Steel works beautifully for precision laser cutting. It absorbs laser energy well. Clean cuts happen with minimal distortion. Stainless varieties hold tolerances from ±0.002 to ±0.005 inches consistently.

Aluminum cuts fast but requires careful setup. Its reflective surface can cause power variations if handled improperly. Smart operators adjust parameters to compensate.

Non-metals often cut even more precisely:

- Acrylic produces glass-smooth edges

- Wood needs balanced speed to avoid burning

- Plastics achieve incredibly tight tolerances with proper technique

Material preparation matters too. Flat, clean sheets produce better results than warped or dirty ones.

How Laser Cutting Compares to Other Methods

Plasma cutting works great for thick steel but struggles with precision. Typical tolerances run ±0.020 inches – four times looser than laser cutting. Heat creates larger affected zones around cuts.

Waterjet cutting avoids heat completely and cuts virtually anything. However, it’s slower and more expensive for most jobs. Tolerances around ±0.008 inches beat plasma but trail laser cutting.

| Method | Tolerance | Speed | Material Limits |

| Laser | ±0.005″ | Fast | Thickness limited |

| Plasma | ±0.020″ | Fast | Metals only |

| Waterjet | ±0.008″ | Slow | Cuts everything |

CNC machining still wins for super-tight tolerances on thick parts. Laser cutting dominates sheet metal work though.

Which Laser Cutters Are Most Accurate

Fiber lasers rule metal cutting today. They focus tighter than older CO2 systems and achieve ±0.003 inches routinely. Beam quality stays consistent even at high power.

CO2 lasers handle more materials but typically hold ±0.005 inches. They excel at non-metals like wood and acrylic where fiber lasers struggle.

UV lasers represent ultimate precision. These specialized machines reach ±0.0001 inches for micro-machining applications. Medical device makers and electronics manufacturers rely on this extreme accuracy.

Choosing the right laser depends on materials, volumes, and tolerance requirements. Laser cutting services help match technology to applications.

What Design Factors Optimize Accuracy

Smart designers think about laser cutting from the start. Parts designed for stamping or machining might not optimize laser capabilities.

Key design principles:

- Specify realistic tolerances for applications

- Account for kerf width in tight-fitting assemblies

- Avoid unnecessarily tight tolerances that increase costs

- Consider how parts nest together on sheets

Kerf (cut width) matters more than many realize. Each cut removes material. Assemblies need compensation. CAD software handles this automatically when set up properly.

The National Institute of Standards and Technology publishes guidelines that help designers optimize parts for manufacturing processes including laser cutting.

What Preparations Enhance Precision

Good preparation separates excellent shops from average ones. Material inspection catches problems before cutting starts. Thickness variations, surface contamination, or warping all affect final accuracy.

Smart shops check:

- Material thickness consistency across sheets

- Surface cleanliness and condition

- Chemical composition matching specifications

- Flatness within acceptable limits

Machine preparation matters equally. Daily calibration catches drift before affecting parts. Lens cleaning maintains beam quality. Alignment checks ensure heads move exactly where programmed.

What Safety Measures Ensure Precise Cutting

Safety and precision go hand in hand. Trained operators understand both staying safe and achieving accurate results. Proper safety procedures prevent accidents that could damage equipment and ruin precision.

Essential safety elements:

- Comprehensive operator training on equipment and materials

- Regular safety system checks and maintenance

- Proper ventilation to remove cutting fumes

- Eye protection from laser radiation

Well-maintained safety systems also protect expensive precision equipment. Damaged machines can’t hold tight tolerances.

What Role Does Maintenance Play

Maintenance makes or breaks precision laser cutting operations. Clean optics maintain beam quality. Proper alignment keeps cuts where they belong. Regular calibration prevents drift over time.

Critical maintenance tasks:

- Daily lens and mirror cleaning

- Weekly alignment verification

- Monthly calibration checks

- Quarterly comprehensive inspections

Shops that skip maintenance see accuracy degrade gradually. By the time problems become obvious, many parts might be out of specification.

Why Accuracy Matters in Manufacturing

The precision laser cutting machine market hit $5.94 billion in 2023. It continues growing at 7.6% annually through 2032. This growth stems from manufacturers demanding ever-tighter tolerances.

Accurate parts save money throughout supply chains. They fit together properly during assembly, reducing labor costs and rework. They meet specifications consistently, preventing customer returns.

Automotive manufacturers drive much of this demand, accounting for 38% of the market in 2023. Aerospace and medical device companies push even tighter requirements where safety depends on precision.

How Yicen Excels in Cutting Accuracy

Yicen Precision built their reputation on consistently delivering tight tolerances across diverse industries. Their combination of advanced equipment and skilled operators produces results that meet demanding specifications.

Their capabilities include:

- Latest fiber and CO2 laser technology

- ISO 9001:2015 certified quality systems

- Advanced measurement and inspection equipment

- Experienced engineering support for complex projects

Whether aerospace components or medical devices, Yicen handles projects where precision matters. Their CNC machining services complement laser cutting for complete manufacturing solutions.

Conclusion

Precision Laser Cutting delivers the accuracy modern manufacturing demands. Success depends on understanding material behavior, machine capabilities, and proper preparation. Smart manufacturers partner with experienced shops that invest in equipment, training, and quality systems.

The technology continues advancing, with tighter tolerances and new materials becoming possible. Companies that embrace these capabilities gain competitive advantages through better products and lower costs.

FAQs on precision Laser Cutting

What tolerance can I expect from laser cutting?

Does material thickness affect cutting accuracy?

Which laser type gives the best accuracy for metals?

How do I maintain accuracy in production runs?

What affects laser cutting precision most?

Citations:

- National Institute of Standards and Technology. “Manufacturing Engineering.” NIST.gov. https://www.nist.gov/

- ADH Machine Tool. “Laser Cutting Machine Tolerance Guide.” October 2024.

- A-Laser Precision. “Standard Laser Cutting Tolerances.” January 2025.

- Global Market Insights. “Laser Cutting Machines Market Report.” April 2024.

- ISO Organization. “ISO 9013 Thermal Cutting Standards.” 2024.