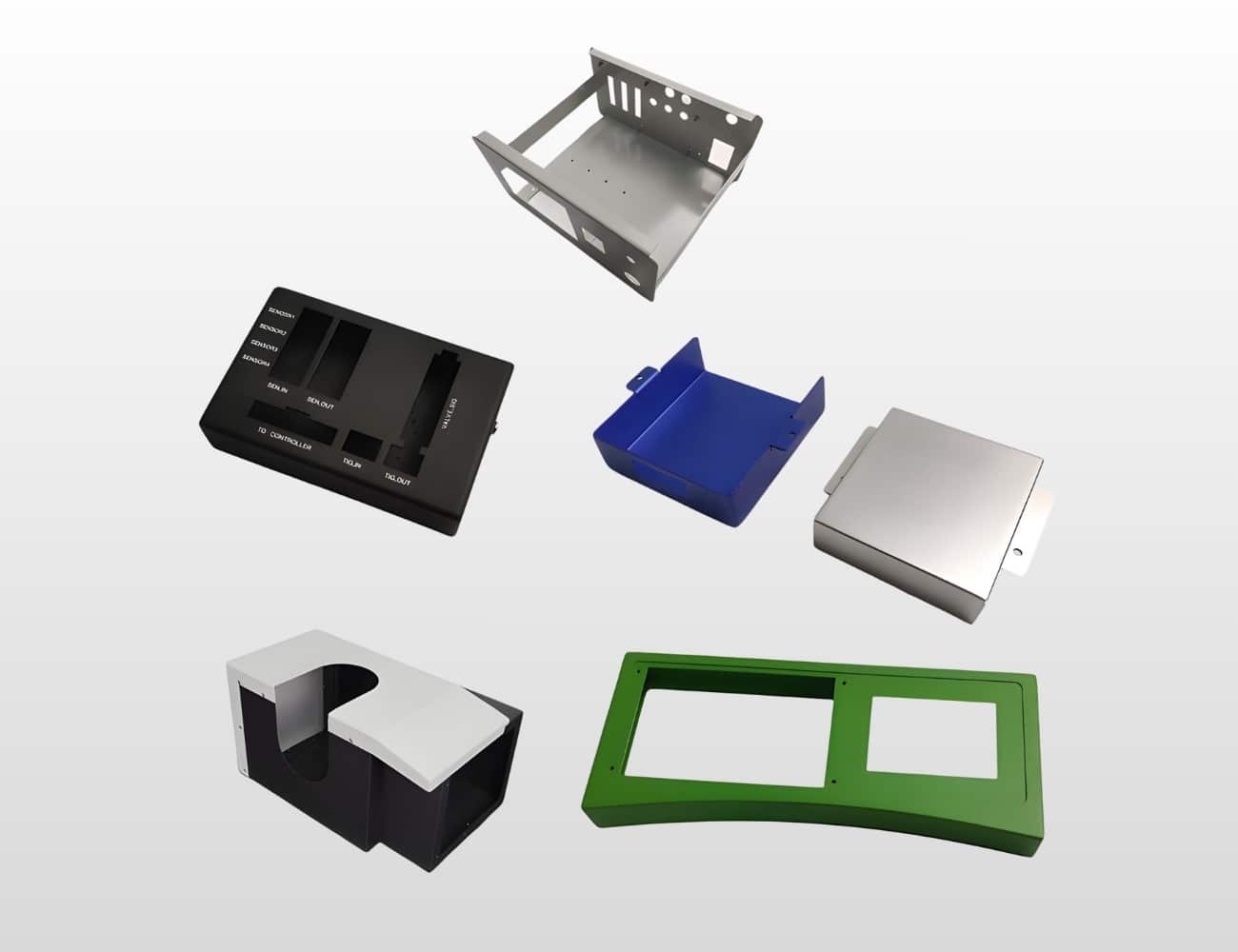

O que são caixas para painéis de controlo?

As caixas dos painéis de controlo são armários de proteção fabricados com precisão que alojam controlos eléctricos, controladores lógicos programáveis (PLC), accionamentos de motores, fontes de alimentação, disjuntores e sistemas de cablagem em equipamento de automação. Estes componentes incluem armários de controlo independentes, caixas de junção montadas na parede, painéis de interface do operador, caixas de controlo de máquinas e armários de painéis de distribuição utilizados em instalações de fabrico, unidades de transformação, linhas de embalagem e maquinaria industrial. Cada caixa tem de proporcionar segurança eléctrica de acordo com as classificações NEMA ou IP, proteger os componentes do pó e da humidade, facilitar a dissipação do calor, suportar a montagem do equipamento e permitir o acesso para manutenção e resolução de problemas. A qualidade dos invólucros dos painéis de controlo de precisão tem um impacto direto na fiabilidade do sistema elétrico, na segurança do operador e no tempo de funcionamento do equipamento em todas as aplicações de automação.

Principais requisitos técnicos

O fabrico de caixas para painéis de controlo exige uma engenharia de precisão versátil. As tolerâncias típicas variam entre ±0,015″ para dimensões gerais do armário até ±0,005″ para padrões de orifícios de montagem, localizações de dobradiças e caraterísticas de alinhamento da porta que garantem um ajuste e funcionamento corretos. As especificações do material incluem ligas de alumínio (5052, 6061) para uma resistência à corrosão ligeira, aço inoxidável (304, 316) para processamento de alimentos e ambientes químicos, aço-carbono (aço laminado a frio) com revestimento em pó para uso industrial geral, e aço galvanizado para aplicações no exterior.

Os requisitos de acabamento da superfície equilibram a funcionalidade com a aparência. As superfícies de montagem internas precisam de Ra 125 micropolegadas para a instalação do equipamento. As superfícies exteriores são normalmente revestidas a pó ou pintadas para proteção contra a corrosão e para um aspeto profissional. Os invólucros dos painéis de controlo devem fornecer Classificações NEMA 1, 4, 4X ou 12 (ou classificações IP equivalentes, como IP54, IP65) para proteção ambiental, gestão térmica através de ranhuras de ventilação ou disposições de arrefecimento, pontos de ligação à terra para segurança eléctrica e disposições de entrada de cabos com placas de bucim ou locais de encaixe adequados. Os componentes requerem uma vedação adequada da porta com juntas, planicidade das superfícies de vedação dentro de 0.010″ largura transversal, mecanismos de bloqueio seguros para segurança e construção rígida para suportar o peso do equipamento de 50 a mais de 500 libras, dependendo do tamanho do armário.

Desafios e soluções para o fabrico

A maquinagem de caixas de painéis de controlo apresenta desafios práticos de fabrico. As grandes dimensões dos armários requerem uma grande capacidade das máquinas e do manuseamento de materiais. A construção em chapa metálica fina (normalmente de calibre 14-16) requer um manuseamento cuidadoso para evitar distorções. Conseguir um encaixe correto da porta com folgas mínimas exige uma maquinação e montagem precisas. A acomodação de numerosos orifícios de montagem, recortes para ecrãs e interruptores e pontos de entrada de cabos exige uma programação eficiente.

A Yicen Precision supera estes desafios com capacidades de fabrico versáteis. Os nossos Puncionadeiras de torre CNC criar eficazmente orifícios de montagem, padrões de ventilação e orifícios de entrada de cabos em painéis de chapa metálica. Centros de maquinagem CNC de 5 eixos tratam de recortes complexos para interfaces de operador, janelas de visualização e painéis de conectores com dimensões precisas. Utilizamos Travões de prensa CNC para uma dobragem precisa de painéis e portas, mantendo os ângulos adequados e o controlo dimensional.

O controlo de qualidade garante que as caixas dos painéis de controlo cumprem todos os requisitos funcionais. Verificação dimensional confirma as dimensões do armário, o encaixe da porta e a localização dos orifícios de montagem. Medição da planeza nas superfícies de vedação garante uma compressão adequada da junta para classificações ambientais. Efectuamos testes de adaptação das portas, dobradiças e fechos para verificar o seu bom funcionamento. Cada compartimento do painel de controlo recebe relatórios dimensionais, certificações de materiais e documentação de inspeção garantindo a total conformidade com as normas de armários eléctricos, classificações NEMA e requisitos de qualidade ISO.

Aplicações e casos de utilização

As caixas de painel de controlo maquinadas com precisão desempenham funções de proteção essenciais em diversas aplicações de automação:

- Máquinas de fabrico: Armários de controlo de máquinas, estações de operação e painéis de distribuição de energia para máquinas CNC, linhas de montagem e equipamento de processamento

- Sistemas de embalagem: Painéis de controlo para máquinas de enchimento, equipamento de etiquetagem, embaladoras de caixas e sistemas de paletização com acesso HMI

- Manuseamento de materiais: Armários de controlo de transportadores, painéis de sistemas de triagem e armários de estações de carregamento de AGV para automatização de armazéns

- Sistemas de controlo de processos: Armários PLC, painéis de interface SCADA e caixas de junção de campo para processamento químico, tratamento de água e serviços públicos

- Processamento de alimentos e bebidas: Armários de aço inoxidável para lavagem de linhas de produção alimentar, sistemas de engarrafamento e equipamento de embalagem

- Automação de edifícios: Painéis de controlo de AVAC, caixas de controlo de iluminação e armários de sistemas de controlo de acesso para edifícios inteligentes

- Equipamento industrial de exterior: Caixas NEMA 4X resistentes às intempéries para transportadores exteriores, controlos de bombas e estações de monitorização remota

Por que escolher a Yicen Precision para gabinetes de painel de controle?

A Yicen Precision é especializada na maquinagem CNC de caixas de painéis de controlo com prazos de entrega tão curtos como 1-2 semanas para armários normais e 3-4 semanas para projectos personalizados com caraterísticas ou acabamentos especializados. O nosso fabrico flexível suporta tanto o desenvolvimento de protótipos para novos designs de máquinas (1-5 unidades) como quantidades de produção de 10 a 200+ unidades para construtores de equipamento e integradores de sistemas.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os projectos de armários para efeitos de fabrico e rentabilidade, recomendações de gestão térmica com base em cálculos de carga térmica e orientações de classificação NEMA/IP para ambientes específicos. A nossa documentação de qualidade inclui relatórios dimensionais, certificações de materiais, especificações de revestimento e declarações de conformidade que suportam as normas ISO 9001 e de segurança eléctrica.

A nossa abordagem económica aproveita o processamento eficiente de chapas metálicas, a colocação optimizada para utilização de material e o revestimento em pó em volume para oferecer preços competitivos. Sabemos que as caixas dos painéis de controlo protegem equipamento elétrico dispendioso e garantem a segurança do operador. Quer esteja a construir maquinaria de embalagem, equipamento de processamento ou sistemas de automação personalizados, a nossa experiência assegura que os seus armários oferecem a proteção e fiabilidade que as suas aplicações exigem. Contacte-nos hoje para obter uma consulta técnica e orçamentos rápidos sobre os seus requisitos de fabrico de armários para painéis de controlo.