O que são transportadores e actuadores?

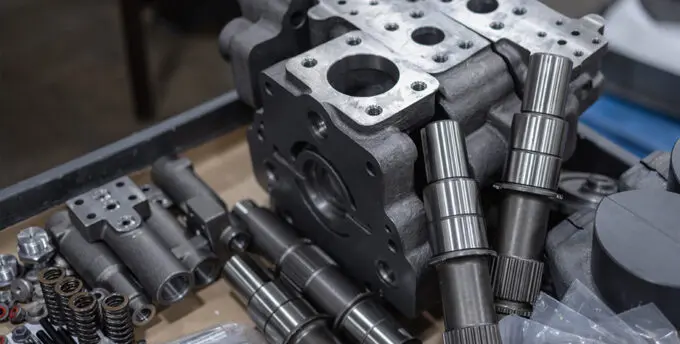

Os transportadores e os actuadores são sistemas mecânicos essenciais que movimentam materiais e controlam o posicionamento do equipamento em instalações automatizadas. Estes componentes incluem eixos de rolos transportadores, rodas dentadas, polias de acionamento, suportes de polia, cilindros actuadores, blocos de montagem, placas de transferência e mecanismos de posicionamento utilizados em fábricas, centros de distribuição, linhas de embalagem e armazéns automatizados. Cada componente deve fornecer um controlo de movimento fiável, suportar cargas repetitivas, suportar o peso do material e integrar-se perfeitamente com motores e controlos. A qualidade dos transportadores e actuadores de precisão tem um impacto direto no rendimento da produção, no tempo de funcionamento do sistema e na eficiência operacional em todas as aplicações de manuseamento de materiais.

Principais requisitos técnicos

O fabrico de transportadores e actuadores exige uma engenharia de precisão robusta. As tolerâncias típicas variam entre ±0,010″ para componentes estruturais a ±0,002″ para superfícies de rolamento, diâmetros de veio e interfaces de montagem que asseguram um alinhamento correto e um funcionamento suave. As especificações do material incluem tipos de aço (1018, 1045, 4140) para veios e partes estruturais, ligas de alumínio (6061-T6) para componentes leves, aço inoxidável (304, 316) para processamento de alimentos e ambientes limpos, e ferro fundido para quadros e caixas resistentes.

Os requisitos de acabamento da superfície equilibram a funcionalidade com o custo. As superfícies dos rolamentos precisam de Ra 63 micropolegadas para um ajuste correto do rolo e do rolamento. Os rolos transportadores requerem Ra 125 micropolegadas para superfícies de contacto com o material. Os componentes do transportador e do atuador devem suportar cargas de 50 a mais de 5.000 libras dependendo da aplicação, dos ciclos de funcionamento contínuo, da carga de impacto da transferência de material e das gamas de temperatura de -20°F a 200°F em ambientes industriais típicos. Os componentes requerem uma retidão adequada do veio dentro de 0,005″ por péA concentricidade do furo para instalação do rolamento, a resistência à corrosão para longevidade e os tratamentos de superfície adequados para resistência ao desgaste em aplicações de ciclo elevado.

Desafios e soluções para o fabrico

A maquinação de transportadores e actuadores apresenta desafios práticos de fabrico. Componentes de grandes dimensões e materiais pesados requerem uma capacidade substancial da máquina e configurações rígidas. Os elevados volumes de produção exigem processos eficientes e mudanças rápidas. A manutenção de uma qualidade consistente em todos os lotes, ao mesmo tempo que se cumprem os objectivos de custo, exige a otimização do processo. Vários comprimentos e diâmetros de eixo necessitam de soluções de fixação flexíveis.

A Yicen Precision supera estes desafios com estratégias de produção comprovadas. Os nossos Centros de torneamento CNC com alimentadores de barras produzem eficazmente veios de transporte, rolos e barras de acionamento em volume com qualidade consistente. Centros de maquinagem de 5 eixos lidam com suportes de montagem complexos, placas de transferência e caixas de actuadores com múltiplas caraterísticas em configurações únicas. Utilizamos sistemas de ferramentas de troca rápida e de trabalho normalizado para tempos de preparação rápidos e tempos de ciclo reduzidos.

O controlo de qualidade garante que os componentes do transportador e do atuador cumprem todos os requisitos operacionais. Inspeção durante o processo monitoriza as dimensões críticas durante os ciclos de produção para detetar precocemente as variações. Verificação da CMM confirma os ajustes dos rolamentos, os padrões dos furos de montagem e as relações geométricas. Efectuamos medição da retidão em veios e hastes, utilizando blocos em V e indicadores de precisão. Cada componente recebe verificação dimensional, certificações de materiais e documentação de qualidade garantir a total conformidade com os requisitos do sistema de manuseamento de materiais e com as normas de qualidade ISO.

Aplicações e casos de utilização

Os transportadores e actuadores fabricados com precisão desempenham funções essenciais em diversas aplicações de automação:

- Centros de distribuição: Rolos de transporte, eixos de transmissão, mecanismos de transferência e actuadores de triagem para automatização de armazéns e manuseamento de embalagens

- Linhas de montagem de fabrico: Transportadores de transferência de produtos, componentes de actuadores pneumáticos e sistemas de posicionamento para a produção automóvel e eletrónica

- Processamento de alimentos e bebidas: Componentes de transportadores em aço inoxidável, caixas de actuadores sanitários e peças de manuseamento de materiais para conformidade com a segurança alimentar

- Sistemas de embalagem: Rolos transportadores de alta velocidade, desviadores de produtos, accionadores de empurradores e componentes de manuseamento de caixas para automatização de embalagens

- Manuseamento de bagagens em aeroportos: Componentes de transportadores pesados, mecanismos de triagem e actuadores de transferência para sistemas de bagagem

- Fabrico de produtos farmacêuticos: Peças de transporte e actuadores de precisão compatíveis com a limpeza para a produção e embalagem de produtos farmacêuticos

- Cumprimento do comércio eletrónico: Componentes de sistemas de triagem, peças de redes de transportadores e actuadores de armazenamento automatizado para centros de distribuição de encomendas

Por que escolher a Yicen Precision para transportadores e atuadores?

A Yicen Precision é especializada na maquinagem CNC de transportadores e actuadores com prazos de entrega tão curtos como 1-2 semanas para componentes padrão e 2-3 semanas para projectos personalizados. O nosso fabrico escalável suporta tanto pequenas encomendas para manutenção e peças de substituição (10-25 unidades) como quantidades de produção de 100 a 1.000+ unidades para construtores e integradores de sistemas.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os projectos com vista à eficiência da produção, orientação na seleção de materiais para ambientes específicos e recomendações de redução de custos através de modificações no projeto. A nossa documentação de qualidade inclui relatórios de inspeção, certificações de materiais e registos de rastreabilidade que suportam a conformidade com a norma ISO 9001 e os requisitos do cliente.

A nossa abordagem económica aproveita a maquinação eficiente da produção, o preço por volume dos materiais e os processos optimizados para oferecer preços competitivos sem sacrificar a qualidade. Compreendemos que os componentes de transportadores e actuadores necessitam de fiabilidade para manter as linhas de produção em funcionamento. Quer esteja a construir novos sistemas de automação, a atualizar transportadores existentes ou a necessitar de componentes de substituição para manutenção, a nossa experiência assegura que as suas peças oferecem a durabilidade e o desempenho que as suas operações exigem. Contacte-nos hoje mesmo para obter consulta técnica e cotações de volume para os seus requisitos de fabrico de transportadores e actuadores.