O que são caixas personalizadas?

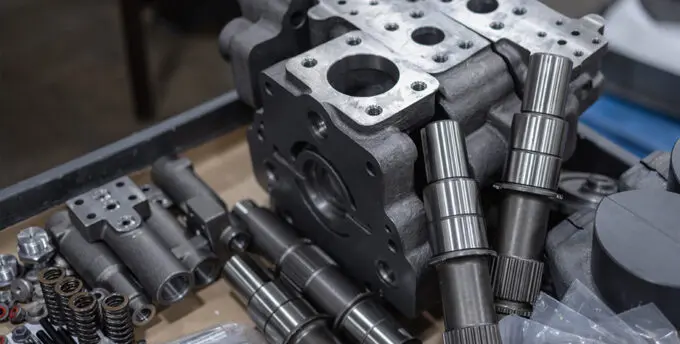

As caixas personalizadas são caixas de proteção fabricadas com precisão, concebidas para proteger equipamentos, componentes electrónicos, motores, sensores e conjuntos mecânicos em sistemas de automação. Estes componentes incluem caixas de motores, caixas de sensores, caixas de painéis de controlo, caixas de junção, caixas de câmaras, coberturas de codificadores e revestimentos de proteção utilizados em robôs industriais, sistemas de visão artificial, equipamento de teste automático e maquinaria de fabrico. Cada caixa tem de fornecer proteção ambiental, suportar a montagem de equipamento, facilitar o encaminhamento de cabos e, por vezes, dissipar o calor, mantendo a acessibilidade para instalação e manutenção. A qualidade das caixas de precisão personalizadas tem um impacto direto na fiabilidade do equipamento, no tempo de funcionamento do sistema e na proteção contra a contaminação em todas as aplicações de automação.

Principais requisitos técnicos

O fabrico de caixas personalizadas exige uma engenharia de precisão versátil. As tolerâncias típicas variam de ±0,010″ para dimensões gerais da caixa a ±0,003″ para superfícies de montagem, ranhuras de vedação e interfaces críticas que garantem um ajuste adequado e proteção ambiental. As especificações do material incluem ligas de alumínio (6061-T6, 7075-T6) para leveza e condutividade térmica, aço inoxidável (304, 316) para ambientes corrosivos, aço macio (1018) com revestimento para uma proteção eficaz em termos de custos, e plásticos de engenharia (PEEK, Ultem) para isolamento elétrico e redução de peso.

Os requisitos de acabamento da superfície equilibram a funcionalidade com o custo. As superfícies de vedação precisam de Ra 63 micropolegadas para uma correta compressão da junta e prevenção de fugas. As superfícies de montagem requerem Ra 125 micropolegadas para uma fixação segura. As caixas personalizadas devem fornecer Graus de proteção IP54 a IP67 contra a entrada de poeira e água, dependendo da aplicação, dissipação térmica para a geração interna de calor, resistência à vibração que cumpre as normas industriais e estabilidade de temperatura de -40°F a 200°F em vários ambientes. Os componentes requerem uma espessura de parede adequada para a rigidez (normalmente 0,125″ a 0,250″), planicidade nas superfícies de vedação dentro de 0.005″, padrões precisos de furos para montagem e conectores, e tratamentos de superfície adequados para proteção contra a corrosão.

Desafios e soluções para o fabrico

A maquinagem de caixas personalizadas apresenta diversos desafios técnicos. Caraterísticas internas complexas, incluindo saliências de montagem, canais de encaminhamento de cabos, aletas do dissipador de calor e folgas dos componentes requerem acesso multi-eixo. As secções de paredes finas necessitam de uma seleção cuidadosa da ferramenta para evitar deflexões e vibrações. Os armários de grandes dimensões com múltiplas caraterísticas exigem uma programação eficiente. Manter a planicidade das superfícies de vedação enquanto se maquinam bolsas internas requer abordagens estratégicas.

A Yicen Precision supera estes desafios com capacidades de fabrico flexíveis. Os nossos Centros de maquinagem CNC de 5 eixos permitem o processamento completo da caixa, incluindo caraterísticas internas, orifícios de montagem e recortes de conectores em configurações mínimas, mantendo a precisão geométrica. Programação CAM avançada optimiza as estratégias de desbaste e acabamento para uma remoção eficiente de material de espaços fechados. Utilizamos técnicas de fresagem adaptativas que ajustam as taxas de avanço com base no engate, evitando a quebra da ferramenta em cantos apertados.

O controlo de qualidade garante que as caixas personalizadas cumprem todos os requisitos funcionais. Inspeção CMM verifica os padrões dos orifícios de montagem, as localizações dos conectores e as relações geométricas. Medição da planeza confirmamos que as superfícies de vedação cumprem as especificações utilizando indicadores de precisão e placas de superfície. Efectuamos testes de adaptação com componentes de acoplamento quando especificados para garantir uma montagem correta. Cada caixa personalizada recebe relatórios dimensionais, certificações de materiais e documentação de inspeção garantir a total conformidade com os requisitos de proteção do equipamento e com as normas de qualidade ISO.

Aplicações e casos de utilização

Os invólucros personalizados maquinados com precisão servem funções de proteção essenciais em diversas aplicações de automação:

- Sistemas de motores industriais: Caixas de motor, coberturas de codificadores e conjuntos de travões para servomotores, motores de passo e variadores de velocidade

- Sistemas de sensores e visão: Caixas de câmaras, caixas de sensores laser e suportes de sensores de proximidade para equipamento de visão artificial e inspeção

- Eletrónica de controlo: Caixas de junção, caixas de controladores e caixas de alimentação para PLCs, accionamentos e controlos de automação

- Efectores finais robóticos: Alojamentos de pinças, corpos de trocadores de ferramentas e coberturas de proteção para ferramentas e acessórios robóticos

- Equipamento para salas limpas: Caixas estanques e caixas de aço inoxidável para o fabrico de semicondutores e automação farmacêutica

- Aplicações em ambientes agressivos: Caixas com classificação IP67 para processamento de alimentos, fábricas de produtos químicos e instalações de automação no exterior

- Máquinas de automação personalizadas: Caixas especiais para equipamento próprio, sistemas de investigação e soluções de automatização únicas

Por que escolher a Yicen Precision para caixas personalizadas?

A Yicen Precision é especializada na maquinagem CNC de caixas personalizadas com prazos de entrega tão curtos como 5-7 dias para caixas simples e 2-3 semanas para projectos complexos com múltiplas caraterísticas. O nosso fabrico flexível suporta tanto o desenvolvimento de protótipos para novas concepções de equipamento (1-5 unidades) como quantidades de produção de 25 a mais de 500 unidades para construtores de equipamento e integradores de sistemas.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os desenhos das caixas em termos de fabrico e custo, recomendações de espessura de parede para rigidez e equilíbrio de peso e orientações de gestão térmica para dissipação de calor. A nossa documentação de qualidade inclui relatórios de inspeção com medições de planicidade, certificações de materiais e registos de rastreabilidade que suportam a conformidade com a norma ISO 9001.

A nossa abordagem económica aproveita estratégias de maquinação eficientes, utilização optimizada de materiais e preços por volume para oferecer preços competitivos. Compreendemos que os invólucros personalizados protegem equipamentos e componentes electrónicos dispendiosos contra danos. Quer esteja a construir robôs industriais, sistemas de visão artificial ou equipamento de automação especializado, a nossa experiência garante que os seus invólucros oferecem a proteção e fiabilidade que as suas aplicações exigem. Contacte-nos hoje mesmo para obter uma consulta técnica e orçamentos rápidos sobre os seus requisitos de fabrico de caixas personalizadas.