O que são caixas de velocidades?

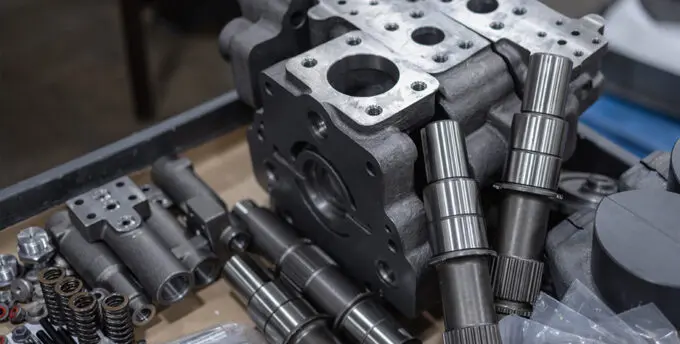

As caixas de velocidades são caixas maquinadas com precisão que alojam engrenagens, rolamentos, veios e sistemas de lubrificação para transmissão de energia em equipamento automatizado. Estes componentes incluem conjuntos de caixas de engrenagens, tampas de rolamentos, placas de extremidade, flanges de montagem e estruturas de suporte de eixos utilizadas em robots industriais, sistemas de transporte, maquinaria automatizada, equipamento CNC e sistemas de manuseamento de materiais. Cada caixa de velocidades tem de proporcionar um alinhamento exato dos rolamentos, manter um espaçamento adequado entre as engrenagens, evitar fugas de lubrificante e suportar as cargas do veio, protegendo simultaneamente os componentes internos da contaminação. A qualidade das caixas de engrenagens de precisão tem um impacto direto na eficiência do equipamento, nos níveis de ruído operacional e nos intervalos de manutenção em todas as aplicações de automação.

Principais requisitos técnicos

O fabrico de caixas de velocidades exige uma maquinação precisa para garantir uma transmissão de potência óptima. As tolerâncias típicas variam entre ±0,010″ para caraterísticas externas da caixa até ±0,0005″ para diâmetros de furo de rolamento e faces de assento de rolamento que asseguram o alinhamento correto do eixo e a engrenagem da engrenagem. As especificações do material incluem ligas de alumínio (356-T6, A380) para aplicações ligeiras, ferro fundido cinzento (classe 30, 40) para caixas tradicionais, ferro fundido dúctil (65-45-12) para necessidades de alta resistência, e fabrico de aço para desenhos personalizados.

Os requisitos de acabamento da superfície são fundamentais para a vedação e o desempenho da chumaceira. Os furos dos rolamentos precisam de Ra 32 micropolegadas ou mais suave para um ajuste correto e longevidade dos rolamentos. As superfícies das juntas requerem Ra 63 micropolegadas com planicidade controlada para uma vedação sem fugas. Os componentes da caixa de velocidades devem suportar cargas de binário de 10 a 10.000+ lb-pé dependendo da aplicação, dos ciclos de funcionamento contínuo, da vibração provocada pelo engrenamento das engrenagens e das gamas de temperatura de -20°F a 200°F em ambientes industriais. Os componentes requerem uma concentricidade do furo do rolamento dentro de 0,001″ TIRO alinhamento paralelo entre os centros dos rolamentos, as folgas adequadas para a expansão térmica e a planura da superfície de montagem dentro de 0.005″ em toda a habitação.

Desafios e soluções para o fabrico

A maquinagem de caixas de velocidades apresenta vários desafios técnicos. Geometrias internas complexas, incluindo bolsas de rolamentos, cavidades de engrenagens, passagens de lubrificação e orifícios de inspeção requerem acesso a vários eixos e seleção estratégica de ferramentas. As peças fundidas de grandes dimensões podem ter uma dureza de material inconsistente e vazios internos. Conseguir um alinhamento preciso do furo do rolamento em longas distâncias entre centros exige configurações rígidas. Manter uma planicidade apertada nas superfícies de vedação enquanto se maquinam bolsas profundas requer uma programação cuidadosa.

A Yicen Precision supera estes desafios com estratégias de fabrico comprovadas. Os nossos Centros de maquinagem CNC de 5 eixos permitem o processamento completo da caixa de velocidades, incluindo caraterísticas internas, furos de rolamentos e superfícies de montagem em configurações coordenadas, mantendo os alinhamentos críticos. Operações avançadas de perfuração e alargamento produzem furos para rolamentos com tolerâncias apertadas e excelente acabamento superficial. Utilizamos técnicas de perfuração coordenadas para garantir que os centros dos rolamentos se alinham dentro das especificações, independentemente do comprimento da caixa.

O controlo de qualidade garante que as caixas de velocidades cumprem todos os requisitos funcionais. Inspeção CMM verifica as dimensões críticas, incluindo os diâmetros dos furos dos rolamentos, as distâncias centro a centro e a perpendicularidade das superfícies de montagem. Medição do calibre do furo confirma as tolerâncias de ajuste dos rolamentos. Efectuamos medição da planeza nas superfícies de vedação, utilizando réguas e indicadores de precisão. Cada caixa de velocidades recebe relatórios dimensionais, certificações de materiais e documentação de inspeção garantir a total conformidade com os requisitos do sistema de acionamento e com as normas de qualidade ISO.

Aplicações e casos de utilização

As caixas de velocidades maquinadas com precisão desempenham funções essenciais em diversas aplicações de automação:

- Robótica industrial: Caixas de engrenagens de precisão para juntas de robôs, actuadores e sistemas de acionamento na automatização do fabrico

- Sistemas de transporte: Carcaças de redutores de velocidade e caixas de transmissão para manuseamento de materiais, linhas de embalagem e sistemas de distribuição

- Máquinas-ferramentas CNC: Caixas de engrenagens de fuso, caixas de acionamento do avanço e caixas de transmissão para centros de maquinagem e tornos

- Veículos guiados automaticamente (AGVs): Caixas de velocidades compactas para sistemas de acionamento de robôs móveis na automatização de armazéns

- Máquinas de embalagem: Componentes de caixas de velocidades de alta velocidade para equipamentos de enchimento, máquinas de etiquetagem e embaladoras de caixas

- Automação de montagem: Caixas de servo-redutores e redutores de precisão para estações de montagem automatizadas e equipamentos de teste

- Processamento de materiais: Caixas de engrenagens resistentes para misturadores, extrusoras e equipamento de processamento industrial

Porquê escolher a Yicen Precision para caixas de velocidades?

A Yicen Precision é especializada na maquinação CNC de caixas de velocidades de precisão com prazos de entrega tão curtos como 1-2 semanas para caixas standard e 3-4 semanas para projectos personalizados complexos. O nosso fabrico flexível suporta tanto o desenvolvimento de protótipos para novos sistemas de acionamento como quantidades de produção de 25 a mais de 500 unidades para fabricantes de equipamento e integradores de sistemas.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os projectos de caixas para fabrico, recomendações de seleção de rolamentos para condições de carga específicas e orientação da superfície de vedação para prevenção de fugas. A nossa documentação de qualidade inclui relatórios de inspeção com medições de furos de rolamentos, certificações de materiais e registos de rastreabilidade que suportam a conformidade com a norma ISO 9001.

A nossa abordagem económica aproveita estratégias de maquinação eficientes, relações estratégicas com fornecedores de fundição e ferramentas optimizadas para oferecer preços competitivos. Compreendemos que as caixas de engrenagens requerem uma precisão que afecta diretamente o desempenho e a fiabilidade do sistema de acionamento. Quer esteja a construir robôs servo-acionados, transportadores pesados ou máquinas-ferramentas de precisão, a nossa experiência garante que as suas caixas de velocidades proporcionam a precisão e a durabilidade que as suas aplicações exigem. Contacte-nos hoje para obter aconselhamento técnico e orçamentos rápidos para as suas necessidades de fabrico de caixas de velocidades.