O que são componentes hidráulicos?

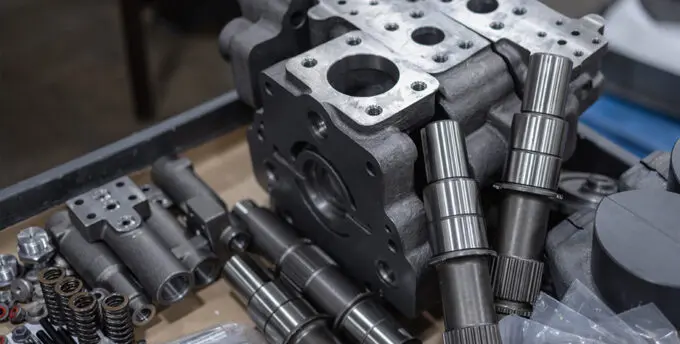

Os componentes hidráulicos são peças maquinadas com precisão que controlam, dirigem e contêm fluido hidráulico pressurizado em sistemas industriais de transmissão de energia. Estas peças críticas incluem corpos de válvulas, blocos de colectores, cilindros, hastes de pistão, adaptadores, acessórios hidráulicos e alojamentos de bombas utilizados em prensas industriais, máquinas de moldagem por injeção, sistemas de fixação automatizados, equipamento de manuseamento de materiais e actuadores robóticos. Cada componente tem de proporcionar uma vedação sem fugas, suportar as pressões do sistema, manter passagens internas precisas para o fluxo de fluido e resistir ao desgaste provocado pelo funcionamento contínuo. A qualidade dos componentes hidráulicos de precisão tem um impacto direto na eficiência do sistema, no tempo de resposta e na fiabilidade operacional em todas as aplicações hidráulicas de automação.

Principais requisitos técnicos

O fabrico de componentes hidráulicos exige uma precisão e uma qualidade de superfície excepcionais. As tolerâncias típicas variam entre ±0,005″ para caraterísticas externas a ±0,0005″ para diâmetros do furo do cilindro, diâmetros da haste do pistão e dimensões da ranhura de vedação que asseguram uma vedação adequada e um funcionamento suave. As especificações do material incluem classes de aço (4140, 4340) para componentes de alta pressão, aço inoxidável (304, 316, 17-4PH) para ambientes corrosivos, ligas de alumínio (6061-T6, 7075-T6) para colectores leves, e ligas de latão (C360, C464) para acessórios e componentes de baixa pressão.

Os requisitos de acabamento da superfície são críticos para o desempenho hidráulico. Os furos dos cilindros precisam de Ra 8-16 micropolegadas conseguido através do afiamento para um funcionamento correto do vedante e um mínimo de fugas. As superfícies da haste do pistão requerem Ra 4-8 micropolegadas com revestimento de crómio duro para resistência ao desgaste. Os componentes hidráulicos devem resistir a pressões de sistema de 1.000 a 5.000 PSI com algumas aplicações que atingem 10.000 PSI, carga de pressão cíclica através de milhões de operações, dimensionamento adequado de portas e especificações de roscas de acordo com as normas SAE ou ISO, e gamas de temperatura de -20°F a 200°F dependendo do tipo de fluido. Os componentes requerem retidão nas hastes do pistão dentro de 0,001″ por pé, concentricidade do furo dentro de 0,001″ TIRA sua estrutura é composta por uma estrutura de rosca, um encaixe de rosca adequado para ligações sem fugas e tratamentos de superfície para proteção contra a corrosão e resistência ao desgaste.

Desafios e soluções para o fabrico

A maquinagem de componentes hidráulicos apresenta desafios técnicos especializados. A obtenção de acabamentos ultra-suaves nos furos dos cilindros requer equipamento de afiação e conhecimentos que vão para além da maquinação normal. Portas internas profundas e perfurações cruzadas para passagens de fluidos exigem ferramentas e técnicas especializadas. As hastes de pistão longas e finas são propensas a deflexão durante o torneamento. A manutenção de tolerâncias de furo apertadas após o tratamento térmico requer controlo do processo e operações de acabamento.

A Yicen Precision supera estes desafios com capacidades especializadas de fabrico hidráulico. Os nossos equipamento de afiação de precisão produz furos de cilindro com um acabamento de superfície excecional, controlo de diâmetro dentro de ±0.0002″e textura adequada da superfície para compatibilidade com a vedação. Capacidades de perfuração profunda permitem furos rectos precisos para passagens internas com rácios de profundidade/diâmetro até 20:1. Utilizamos apoios fixos e suporte do contra-ponto durante as operações de torneamento para manter a retidão e o controlo do diâmetro em hastes de pistão longas.

O controlo de qualidade garante que os componentes hidráulicos cumprem todos os requisitos funcionais. Medição do calibre do furo verifica os diâmetros dos cilindros em vários pontos ao longo do comprimento. Perfilometria de superfície confirma que os acabamentos do furo e da haste cumprem os requisitos de vedação hidráulica. Efectuamos ensaio de pressão em corpos de válvulas e colectores para verificar o desempenho sem fugas a pressões nominais. Cada componente hidráulico recebe relatórios dimensionais, certificados de ensaios de pressão, dados de acabamento de superfícies e certificações de materiais assegurando a total conformidade com os requisitos do sistema de propulsão por fluidos e com as normas de qualidade ISO.

Aplicações e casos de utilização

Os componentes hidráulicos maquinados com precisão servem funções essenciais de potência de fluidos em diversas aplicações de automação:

- Prensas industriais: Tubos de cilindros hidráulicos, colectores de válvulas e blocos de controlo para prensas de estampagem, equipamento de forja e moldagem por compressão

- Máquinas de moldagem por injeção: Cilindros de aperto, corpos de válvulas e colectores hidráulicos para equipamento de moldagem por injeção de plástico e fundição injetada

- Sistemas de manuseamento de materiais: Cilindros hidráulicos, componentes de mecanismos de elevação e válvulas de controlo para empilhadores, elevadores de tesoura e equipamento de elevação automatizado

- Sistemas Robóticos: Componentes compactos de actuadores hidráulicos, corpos de válvulas proporcionais e colectores de precisão para robôs industriais pesados

- Equipamento de montagem automatizado: Componentes de cilindros de aperto, peças de acionamento rápido e elementos de fixação hidráulica para células de fabrico automatizadas

- Equipamento de teste: Cilindros de carga hidráulica, colectores de controlo de pressão e componentes de dispositivos de teste para sistemas de teste e validação de produtos

- Equipamento móvel: Corpos de válvulas hidráulicas, componentes de cilindros e blocos de colectores para equipamento de construção e automatização de máquinas agrícolas

Por que escolher a Yicen Precision para componentes hidráulicos?

A Yicen Precision é especializada na maquinagem CNC de componentes hidráulicos com prazos de entrega tão curtos como 1-2 semanas para componentes padrão e 3-4 semanas para colectores complexos ou componentes que exijam um acabamento especializado. O nosso fabrico flexível suporta tanto o desenvolvimento de protótipos para novos sistemas hidráulicos (5-10 unidades) como quantidades de produção de 50 a mais de 1.000 unidades para fabricantes de equipamento e construtores de sistemas hidráulicos.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os projectos de componentes em termos de integridade de pressão e capacidade de fabrico, recomendações de dimensionamento de portas de acordo com os requisitos de fluxo hidráulico e orientação de seleção de materiais para condições específicas de pressão e ambiente. A nossa documentação de qualidade inclui relatórios de inspeção detalhados com medições de furos, certificados de testes de pressão, verificação do acabamento da superfície e certificações de materiais que suportam a conformidade com a norma ISO 9001.

A nossa abordagem económica tira partido de sequências de maquinagem eficientes, capacidades de afiação internas e fornecimento estratégico de materiais para oferecer preços competitivos. Compreendemos que os componentes hidráulicos requerem uma precisão que afecta diretamente o desempenho do sistema e o funcionamento sem fugas. Quer esteja a construir prensas industriais, máquinas de moldagem por injeção ou sistemas hidráulicos automatizados, a nossa experiência garante que os seus componentes proporcionam a fiabilidade e o desempenho que as suas aplicações exigem. Contacte-nos hoje para obter consulta técnica e orçamentos rápidos para os seus requisitos de fabrico de componentes hidráulicos.