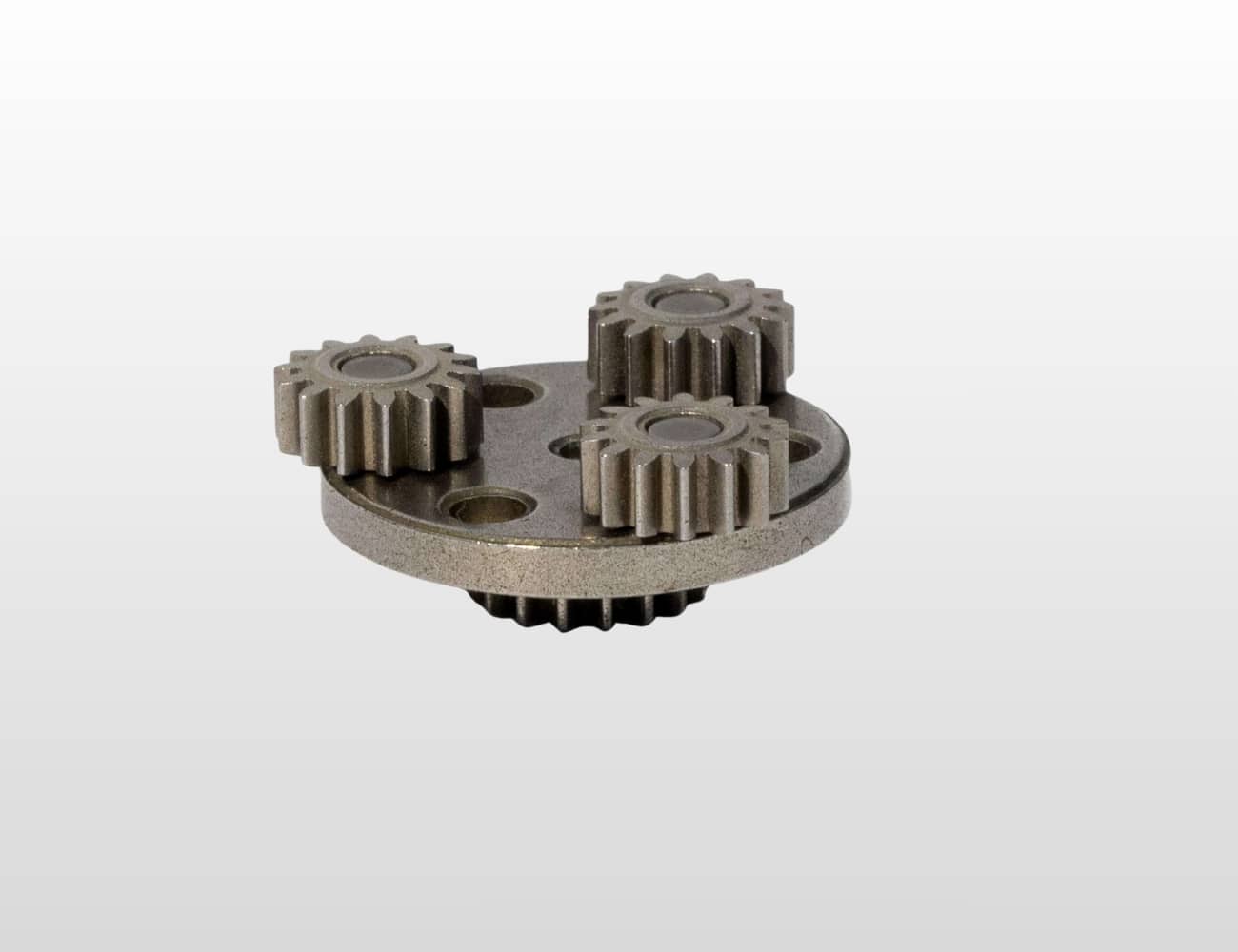

O que são engrenagens de precisão?

As engrenagens de precisão são componentes mecânicos fabricados com precisão, com dentes formados com exatidão, que se engrenam para transmitir movimento rotativo e binário entre veios. Estas peças essenciais incluem engrenagens de dentes retos, engrenagens helicoidais, engrenagens cónicas, engrenagens sem-fim, conjuntos de cremalheira e pinhão e componentes de engrenagens planetárias utilizados em robôs industriais, sistemas servo, máquinas CNC, equipamento de montagem automatizado e sistemas de manuseamento de materiais. Cada engrenagem tem de manter um perfil preciso dos dentes, um diâmetro de passo adequado, um espaçamento correto e um acabamento superficial suave para garantir uma transmissão de energia eficiente, um ruído mínimo e uma longa vida útil. A qualidade das engrenagens de precisão personalizadas tem um impacto direto na eficiência do sistema, na precisão do posicionamento e na fiabilidade mecânica em todas as aplicações de automação.

Principais requisitos técnicos

O fabrico de engrenagens de precisão exige um controlo dimensional exato e um processo especializado. As tolerâncias típicas variam entre ±0,005″ para dimensões do bloco da engrenagem até ±0,0005″ para espaçamento entre dentes, precisão de perfil e variações de chumbo que asseguram uma malha suave e uma distribuição de carga adequada. As especificações do material incluem tipos de aço (4140, 4340, 8620) para engrenagens de alta resistência que requerem tratamento térmico, aço inoxidável (303, 304, 17-4PH) para ambientes corrosivos, ligas de bronze (C932, C954) para aplicações de parafusos sem-fim, e ligas de alumínio (7075-T6) para engrenagens leves de alta velocidade.

Os requisitos de acabamento da superfície são críticos para o desempenho da engrenagem. Os flancos dos dentes precisam de Ra 32 micropolegadas ou mais suave para um funcionamento silencioso e um desgaste mínimo. As engrenagens retificadas podem exigir Ra 16 micropolegadas para aplicações de precisão. As engrenagens de precisão devem cumprir Classes de qualidade AGMA 7-10 dependendo da aplicação, sendo a classe 8-9 comum para sistemas de automação. Os componentes devem suportar cargas de binário de 1 a 1.000+ lb-péO sistema de controlo de qualidade é um sistema de controlo de qualidade que permite a utilização de um sistema de controlo de qualidade com velocidades de funcionamento de 100 a 10.000 RPM, padrões de contacto de dentes adequados em toda a largura da face e estabilidade de temperatura durante o funcionamento. Os requisitos incluem um diâmetro de passo exato dentro de 0.001″O perfil adequado do dente de acordo com os padrões involutivos, folga controlada (normalmente 0.002 ″ a 0.008 ″) e tratamento térmico adequado para a dureza da superfície (normalmente 58-62 HRC para engrenagens endurecidas por caixa).

Desafios e soluções para o fabrico

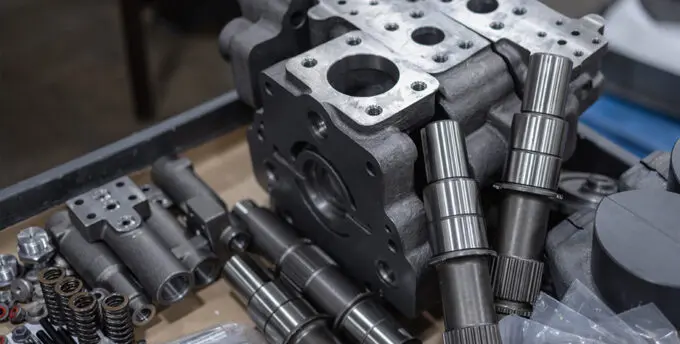

A maquinação de engrenagens de precisão apresenta desafios técnicos especializados. A obtenção de perfis de dentes involutos precisos requer equipamento e ferramentas especializados. A manutenção de um espaçamento consistente dos dentes em toda a circunferência exige uma indexação precisa. Materiais duros e peças em bruto tratadas termicamente criam desgaste da ferramenta e alterações dimensionais. Minimizar a distorção durante o tratamento térmico e manter tolerâncias apertadas requer um controlo cuidadoso do processo.

A Yicen Precision supera estes desafios com capacidades especializadas de fabrico de engrenagens. Os nossos Máquinas de fresagem de engrenagens CNC produzem perfis de dentes involutos precisos com espaçamento consistente e ângulos de avanço adequados para engrenagens de dentes retos e helicoidais. Fresagem CNC de 5 eixos com software de corte de engrenagens permite a produção de engrenagens cónicas e perfis de dentes personalizados. Utilizamos retificação de precisão para o acabamento de engrenagens endurecidas de acordo com as tolerâncias finais e os requisitos de acabamento superficial.

O controlo de qualidade garante que as engrenagens de precisão cumprem todos os requisitos funcionais. Equipamento de inspeção de engrenagens mede o perfil do dente, o avanço, o passo e a excentricidade utilizando analisadores de engrenagens especializados ou CMM com software de engrenagens. Testadores de engrenagens de rolamento verificar se a malha é suave e se os padrões de contacto dos dentes são adequados. Efectuamos medição da folga utilizando pinos e indicadores de precisão. Cada engrenagem de precisão recebe relatórios dimensionais, análises de qualidade de engrenagens, certificações de materiais e documentação de tratamento térmico garantindo a total conformidade com os requisitos de transmissão de energia e com as normas de qualidade ISO.

Aplicações e casos de utilização

As engrenagens maquinadas com precisão desempenham funções essenciais de transmissão de potência em diversas aplicações de automação:

- Robótica industrial: Engrenagens de alta precisão para actuadores de juntas de robôs, accionamentos harmónicos e caixas de engrenagens planetárias que requerem um posicionamento preciso

- Máquinas-ferramentas CNC: Engrenagens de acionamento do fuso, engrenagens do mecanismo de alimentação e componentes do trocador de ferramentas para centros de maquinagem e tornos

- Sistemas de servo-motores: Redutores de precisão, engrenagens de codificação e engrenagens de acoplamento para sistemas de posicionamento de alta precisão

- Equipamento de montagem automatizado: Engrenagens de temporização, componentes de acionamento do índice e engrenagens do mecanismo de transferência para operações sincronizadas

- Máquinas de embalagem: Engrenagens de alta velocidade para equipamentos de enchimento, máquinas de etiquetagem e sistemas de cartonagem que requerem um tempo preciso

- Sistemas de manuseamento de materiais: Engrenagens de acionamento de transportadores, mecanismos de elevadores e engrenagens de sistemas de triagem para automatização de armazéns

- Automação de dispositivos médicos: Engrenagens de precisão em miniatura para robôs cirúrgicos, equipamento de diagnóstico e sistemas de fabrico de produtos farmacêuticos

Por que escolher a Yicen Precision para engrenagens de precisão?

A Yicen Precision é especializada na maquinagem CNC de engrenagens de precisão com prazos de entrega tão curtos como 2-3 semanas para engrenagens padrão e 3-4 semanas para projectos complexos que exijam retificação ou tratamento térmico especial. O nosso fabrico flexível suporta o desenvolvimento de protótipos para novos sistemas de acionamento (5-10 unidades) e quantidades de produção de 50 a mais de 1.000 unidades para fabricantes de equipamento e construtores de sistemas.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os projectos de engrenagens em termos de capacidade de fabrico e desempenho, orientação de seleção de materiais para requisitos específicos de carga e velocidade, e recomendações de tratamento térmico para a dureza e resistência ao desgaste pretendidas. A nossa documentação de qualidade inclui relatórios detalhados de inspeção de engrenagens, análise do padrão de contacto dos dentes, certificações de materiais e registos de tratamento térmico que apoiam a conformidade com a norma ISO 9001.

A nossa abordagem económica aproveita processos eficientes de corte de engrenagens, coordenação interna de tratamento térmico e fornecimento estratégico de materiais para oferecer preços competitivos. Compreendemos que as engrenagens de precisão requerem uma exatidão que tem um impacto direto no desempenho e fiabilidade do sistema. Quer esteja a construir robôs servo-acionados, equipamento de embalagem de alta velocidade ou máquinas-ferramentas de precisão, a nossa experiência garante que as suas engrenagens proporcionam a suavidade e a durabilidade que as suas aplicações exigem. Contacte-nos hoje para obter uma consulta técnica e orçamentos rápidos para as suas necessidades de fabrico de engrenagens de precisão.