O que é a prototipagem de automação?

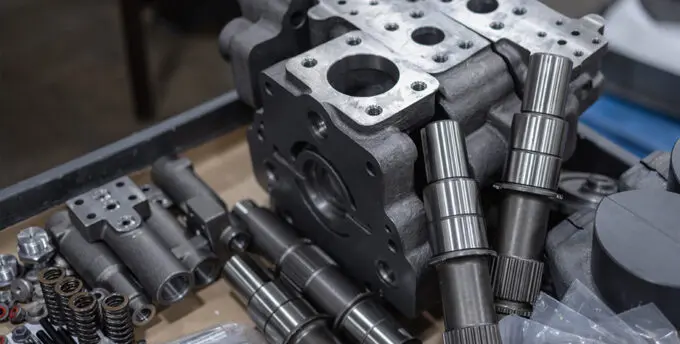

A prototipagem de automação é o processo de criação de componentes e conjuntos funcionais e testáveis a partir de projectos CAD para validar conceitos de engenharia antes da produção em massa. Os protótipos incluem tudo, desde componentes robóticos e suportes de sensores a caixas de engrenagens e actuadores personalizados que replicam a geometria da produção e as propriedades dos materiais. A prototipagem é utilizada em departamentos de I&D, equipas de desenvolvimento de robótica, grupos de engenharia de construtores de máquinas, centros de design de integradores de sistemas e empresas em fase de arranque que desenvolvem novos produtos de automação. A função crítica envolve a verificação da exatidão dimensional, o teste das propriedades mecânicas e da durabilidade, a validação dos processos de montagem e da adaptação, a identificação de melhorias na conceção e reduções de custos, a aceleração do tempo de colocação no mercado através da iteração rápida e o fornecimento de amostras físicas para demonstrações, feiras comerciais e apresentações a clientes antes de se comprometerem com ferramentas de produção dispendiosas e com o fabrico de grandes volumes.

Principais requisitos técnicos

A maquinagem CNC de protótipos exige flexibilidade para acomodar alterações frequentes no design, mantendo a precisão ao nível da produção. As tolerâncias típicas variam entre ±0,005″ a ±0,010″ para protótipos funcionais, com tolerâncias mais apertadas de ±0,001″ a ±0,002″ disponíveis para caraterísticas críticas que exijam precisão na produção final. As especificações dos materiais devem corresponder aos materiais de produção pretendidos, incluindo ligas de alumínio (6061, 7075), tipos de aço (1018, 4140, 4340), aço inoxidável (303, 304, 316, 17-4PH), plásticos de engenharia (Delrin, PEEK, Ultem) e materiais especiais como bronze ou aço para ferramentas.

Os requisitos de acabamento da superfície variam consoante a aplicação. As superfícies funcionais necessitam de Ra 63-125 micropolegadas para uma montagem e deslocação corretas, enquanto as superfícies cosméticas podem exigir Ra 32-63 micropolegadas para validação do aspeto. Os requisitos de documentação incluem relatórios dimensionais, certificações de materiais e desenhos "as-built" quando são efectuadas alterações. Os protótipos devem representar com exatidão o desempenho da peça de produção para testes em condições reais de funcionamento, incluindo testes de carga, validação do ciclo de movimento, verificação do desempenho térmico e testes de integração para garantir a prontidão do projeto antes do compromisso de produção.

Desafios e soluções para o fabrico

A criação de protótipos apresenta desafios únicos, incluindo prazos apertados com um tempo de execução mínimo, revisões frequentes do projeto que exigem abordagens de programação flexíveis, trabalho a partir de modelos CAD preliminares que podem não ter detalhes completos de fabrico, equilíbrio entre velocidade e precisão para resultados de testes significativos e gestão de custos ao mesmo tempo que se utilizam materiais com intenção de produção. A produção de peças únicas ou de baixa quantidade carece de economia de escala, tornando as estratégias de maquinação eficientes essenciais para o controlo de custos.

A Yicen Precision supera estes desafios com fluxos de trabalho de prototipagem dedicados, optimizados para uma rápida execução sem sacrificar a qualidade. O nosso software CAM avançado permite uma programação rápida a partir de vários formatos CAD (STEP, IGES, SolidWorks, Parasolid) com reconhecimento automático de caraterísticas. Mantemos um extenso inventário de ferramentas, eliminando atrasos nas encomendas de ferramentas especiais. Os maquinistas experientes podem trabalhar a partir de modelos incompletos, fornecendo feedback DFM aos projectistas durante a fase de prototipagem.

A programação prioritária assegura que os projectos de protótipos recebem atenção imediata com tempo de máquina dedicado. As soluções de fixação personalizadas adaptam-se rapidamente a novas geometrias utilizando sistemas modulares e mordentes macios. O nosso controlo de qualidade inclui inspeção CMM de dimensões críticas, recomendações de testes funcionais com base nos requisitos da aplicação e pacotes de documentação detalhada para apoiar a validação do projeto e decisões de iteração para melhoria contínua.

Aplicações e casos de utilização

A maquinação CNC de protótipos serve diversas aplicações de desenvolvimento de automação:

- Desenvolvimento de robótica: Protótipos de braços de robôs, caixas de juntas, componentes de pinças e suportes de actuadores para novos designs de robôs e testes de prova de conceito

- Equipamento de automação industrial: Componentes de máquinas personalizados, protótipos de fixação e ferramentas de montagem para o desenvolvimento de novos equipamentos de fabrico

- Sistemas de controlo de movimento: Protótipos de caixas de engrenagens, componentes de corrediças lineares e suportes de servomotores para validação e teste de sistemas de movimento

- Projectos de integração de sensores: Caixas de sensores personalizadas, suportes de montagem e adaptadores de interface para visão mecânica e desenvolvimento de sistemas de medição

- Inovação no manuseamento de materiais: Protótipos de componentes de transportadores, peças de mecanismos de transferência e elementos de sistemas de triagem para novos conceitos de manuseamento de materiais

- Desenvolvimento de produtos para empresas em fase de arranque: Peças de protótipos iniciais para novos produtos de automatização, demonstrações para investidores e campanhas de financiamento coletivo

- Investigação e desenvolvimento: Projectos de investigação universitária, programas de inovação financiados pelo governo e iniciativas empresariais de I&D que requerem protótipos funcionais

Porquê escolher a Yicen Precision para a criação de protótipos?

A Yicen Precision é especializada na maquinagem CNC de prototipagem rápida com prazos de entrega tão curtos como 2-5 dias para peças simples e 1-2 semanas para montagens complexas. Oferecemos um serviço rápido para projectos urgentes, quando necessário. A nossa abordagem escalável suporta peças de protótipo único para validação inicial do conceito através de séries de pré-produção de baixo volume de 25-100 unidades para testes alargados e programas piloto.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os desenhos para prototipagem e produção futura, recomendações de redução de custos que identificam caraterísticas dispendiosas ou tolerâncias que podem ser reduzidas, e sugestões de materiais alternativos quando os materiais de produção não são ideais para a prototipagem. A documentação completa com relatórios de inspeção, certificações de materiais e registos digitais assegura a rastreabilidade ao longo dos ciclos de desenvolvimento.

As nossas soluções de prototipagem com uma boa relação custo-eficácia tiram partido de estratégias de programação eficientes, fornecimento estratégico de materiais com disponibilidade rápida e fluxos de trabalho simplificados que fornecem peças com qualidade de produção a velocidades de protótipo sem comprometer a precisão e a funcionalidade exigidas pelos seus projectos de desenvolvimento de automação. Compreendemos a importância da velocidade nos ciclos de desenvolvimento de produtos. Contacte-nos hoje com os seus ficheiros CAD para consulta técnica e orçamentos de maquinagem CNC de prototipagem rápida.