O que são braços e articulações robóticos?

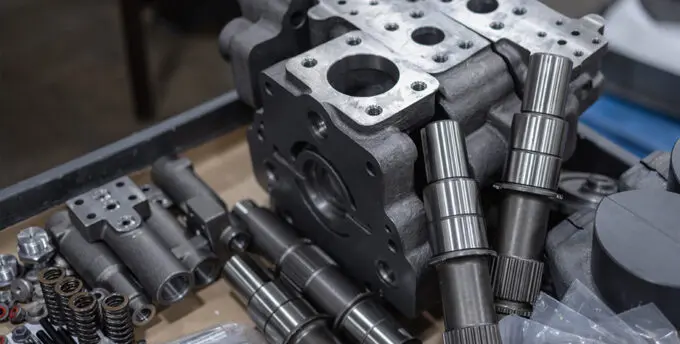

Os braços e articulações robóticos são componentes mecânicos de engenharia de precisão que permitem o movimento controlado em sistemas automatizados. Estas peças incluem segmentos de braços articulados, caixas de juntas rotativas, rolamentos pivotantes, suportes de actuadores, adaptadores de extremidades e caixas de engrenagens utilizadas em robôs industriais, robôs colaborativos (cobots), sistemas pick-and-place, robôs de soldadura e automação de montagem. Cada componente deve proporcionar um movimento suave, manter a exatidão posicional, suportar ciclos de carga repetidos e integrar-se perfeitamente com motores e sensores. A qualidade dos braços e articulações robóticos de precisão tem um impacto direto no desempenho do robô, na eficiência da produção e nos requisitos de manutenção em todas as operações de fabrico automatizadas.

Principais requisitos técnicos

O fabrico de braços e articulações robóticos exige uma engenharia de precisão para garantir um desempenho ótimo. As tolerâncias típicas variam entre ±0,005″ para componentes estruturais a ±0,001″ para superfícies de rolamento, pontos de articulação e interfaces de montagem de engrenagens que asseguram um movimento suave e uma folga mínima. As especificações do material incluem ligas de alumínio (6061-T6, 7075-T6) para braços ligeiros, classes de aço (4140, 4340) para aplicações de carga elevada, aço inoxidável (304, 316) para ambientes de sala limpa, e plásticos de engenharia para aplicações específicas.

Os requisitos de acabamento da superfície são críticos para as peças móveis. As superfícies dos rolamentos precisam de Ra 32 micropolegadas ou mais suave para redução do atrito e resistência ao desgaste. As superfícies de montagem requerem Ra 63 micropolegadas para uma montagem e distribuição de carga corretas. Os componentes robóticos devem resistir a capacidades de carga útil de 5 a mais de 500 libras dependendo do tamanho do robô, ciclos de movimentos repetitivos que excedem milhões de operações, vibração de movimentos a alta velocidade e gamas de temperatura de 32°F a 150°F em ambientes industriais típicos. Os componentes requerem uma concentricidade de furo precisa dentro de 0,002″ TIRA resistência à corrosão é a chave para a longevidade do produto, as tolerâncias de planicidade para as superfícies de montagem, as folgas adequadas para a passagem dos cabos e a resistência à corrosão para a longevidade.

Desafios e soluções para o fabrico

A maquinagem de braços e articulações robóticos apresenta vários desafios técnicos. Geometrias complexas, incluindo secções de braço ocas, passagens de cabos internas, superfícies de montagem múltiplas em vários ângulosAs secções de parede fina em designs leves são propensas a deformações durante o corte. As secções de parede fina em designs leves são propensas a deflexão durante o corte. Grandes segmentos de braço combinados com tolerâncias apertadas exigem estabilidade térmica. A obtenção de superfícies de rolamento lisas, mantendo um controlo dimensional rigoroso, requer um planeamento cuidadoso do processo.

A Yicen Precision supera estes desafios com estratégias de fabrico avançadas. Os nossos Centros de maquinagem CNC de 5 eixos permitem o processamento completo de peças, incluindo furos angulares, superfícies de montagem e caraterísticas internas em configurações únicas, mantendo a precisão e reduzindo o tempo de configuração. Programação CAM avançada optimiza os percursos das ferramentas para uma remoção eficiente do material, evitando a deflexão em secções de paredes finas. Utilizamos fixações especializadas e suportes de trabalho a vácuo para um posicionamento seguro das peças durante a maquinação em várias faces.

O controlo de qualidade garante que os componentes robóticos cumprem todos os requisitos funcionais. Inspeção CMM verifica as dimensões críticas, incluindo os diâmetros dos furos, os padrões dos furos de montagem e a planicidade da superfície. Medição do acabamento da superfície confirma que as áreas de apoio cumprem os requisitos de suavidade. Efectuamos testes de adaptação com os componentes de acoplamento, quando especificado, para garantir uma montagem correta. Cada braço robótico e componente de articulação recebe relatórios dimensionais, certificações de materiais e documentação de inspeção garantir a total conformidade com os requisitos do sistema de automatização e com as normas de qualidade ISO.

Aplicações e casos de utilização

Os braços e articulações robóticos maquinados com precisão desempenham funções essenciais em diversas aplicações de automação:

- Fabrico industrial: Robôs de linha de montagem, sistemas de manuseamento de materiais e equipamento de soldadura automatizado para a produção automóvel e eletrónica

- Automatização de armazéns: Robôs de seleção, sistemas de triagem e sistemas de recuperação de armazenamento automático para centros de logística e distribuição

- Processamento de alimentos: Componentes robóticos higiénicos em aço inoxidável para automação do manuseamento, embalagem e processamento de alimentos

- Fabrico de dispositivos médicos: Robôs de precisão para montagem, teste e embalagem de dispositivos médicos em ambientes de sala limpa

- Robótica colaborativa (Cobots): Componentes e articulações de braços leves para robôs colaborativos seguros para o ser humano no fabrico flexível

- Montagem de eletrónica: Componentes robóticos de alta precisão para manuseamento de PCB, colocação de componentes e automatização de testes

- Embalagem e paletização: Braços e articulações robóticos para trabalhos pesados para linhas de embalagem de alta velocidade e sistemas de paletização de armazéns

Porquê escolher a Yicen Precision para braços e articulações robóticos?

A Yicen Precision é especializada na maquinagem CNC de juntas de braços robóticos de precisão com prazos de entrega tão curtos como 5-7 dias para componentes padrão e 2-3 semanas para projectos personalizados complexos. O nosso fabrico flexível suporta o desenvolvimento de protótipos para novos designs de robôs e quantidades de produção de 10 a mais de 1.000 unidades para integradores de sistemas e OEMs.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM para otimizar os designs para a capacidade de fabrico, recomendações de redução de peso para melhorar a velocidade do robô e orientação de seleção de materiais para ambientes específicos. A nossa documentação de qualidade inclui relatórios de inspeção, certificações de materiais e registos de rastreabilidade que suportam a conformidade com a norma ISO 9001 e os requisitos de qualidade do cliente.

A nossa abordagem económica aproveita a programação eficiente, o fornecimento estratégico de materiais e as estratégias de maquinação optimizadas para oferecer preços competitivos. Compreendemos que os componentes robóticos requerem uma precisão que tem um impacto direto no desempenho e fiabilidade do sistema. Quer esteja a construir robôs colaborativos, manipuladores industriais ou