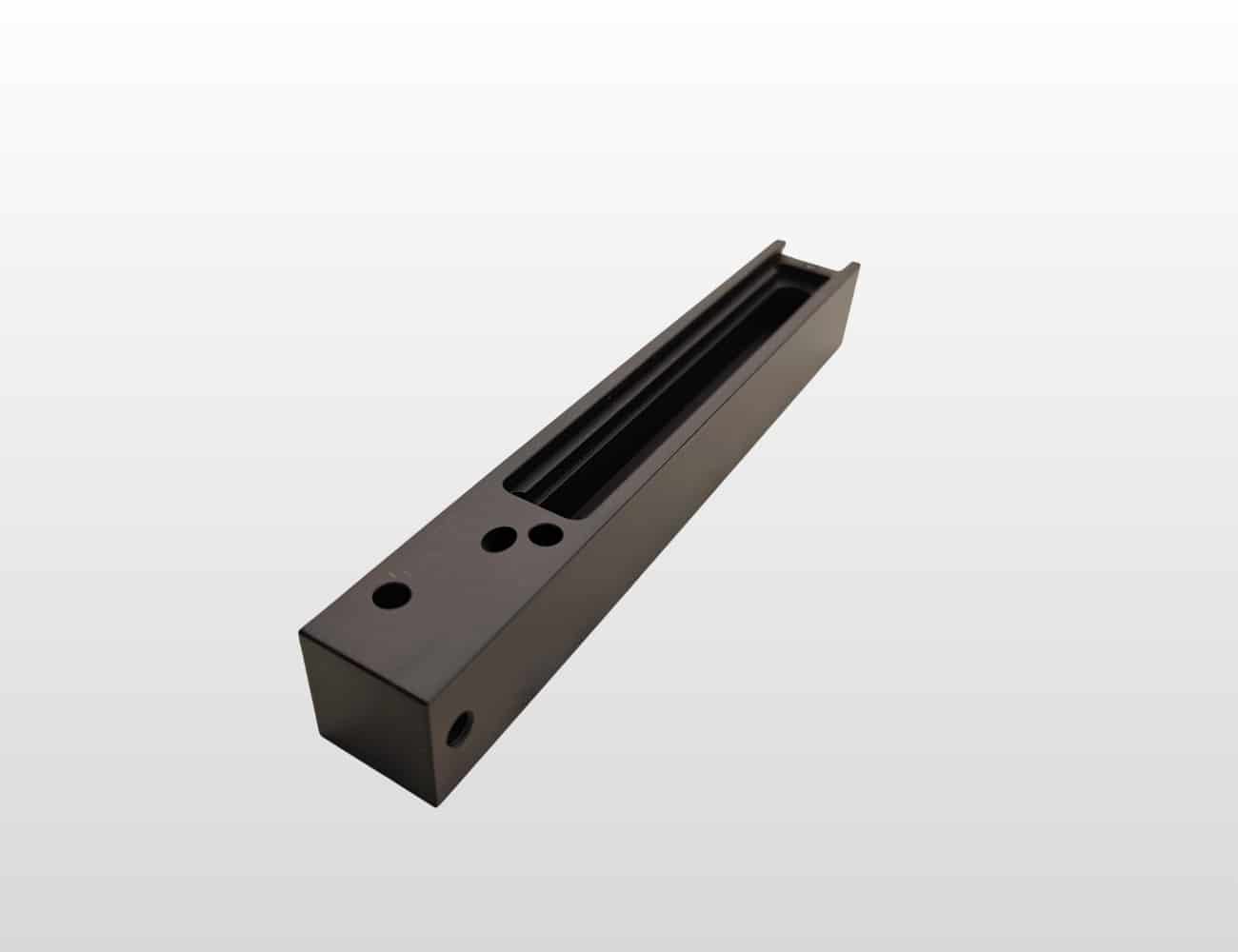

What are Sensor Mounts?

Sensor mounts are precision-machined positioning brackets and fixtures that securely hold sensors, cameras, encoders, and measurement devices at specific locations and orientations in automation systems. These components include camera mounting brackets, proximity sensor housings, encoder adapters, laser sensor mounts, vision system fixtures, and adjustable positioning brackets used throughout machine vision inspection, robotic guidance systems, automated quality control, and industrial measurement equipment. Each mount must provide rigid positioning, maintain accurate alignment, resist environmental vibration, and sometimes allow controlled adjustment for sensor calibration. The quality of precision sensor mounts directly impacts measurement accuracy, system reliability, and inspection consistency across all automation sensing applications.

Principais requisitos técnicos

Manufacturing sensor mounts demands precision engineering for accurate positioning. Typical tolerances range from ±0.010″ for general bracket features to ±0.002″ for sensor interface surfaces, mounting hole locations, and alignment references that ensure accurate sensor positioning. Material specifications include ligas de alumínio (6061-T6, 7075-T6) for lightweight rigidity, aço inoxidável (304, 316) for corrosive or clean room environments, steel (1018, 4140) for heavy-duty applications, and engineering plastics for electrical isolation when required.

Surface finish requirements balance functionality with economics. Sensor interface surfaces need Ra 63 micropolegadas for proper seating and stability. Mounting surfaces require Ra 125 micropolegadas for secure attachment. Sensor mounts must provide positional accuracy within ±0.005″ for proper sensor alignment, maintain stability under vibration conditions from 10-2000 Hz, resist thermal expansion effects across temperature ranges from 40°F to 150°F, and support sensor weights from ounces to several pounds depending on equipment. Components require proper hole patterns for standard sensor mounting, flatness on reference surfaces within 0.003″, appropriate clearances for cable routing and connectors, and sometimes adjustment features like slots or eccentric holes for fine positioning.

Desafios e soluções para o fabrico

Machining sensor mounts presents diverse technical challenges. Complex geometries including angled mounting surfaces, multiple reference planes, adjustment slots, and integrated cable routing require multi-axis capabilities. Lightweight designs with thin sections need careful machining to prevent distortion. Achieving tight positional tolerances on hole patterns across different mounting planes demands precise setup and verification. Balancing rigidity requirements with weight constraints requires design optimization.

Yicen Precision overcomes these challenges with flexible manufacturing approaches. Our Centros de maquinagem CNC de 5 eixos enable complete sensor mount processing including angled surfaces, mounting holes at compound angles, and integrated features in coordinated setups, maintaining geometric relationships. Programação CAM avançada optimizes toolpaths for efficient machining while minimizing part deflection in lightweight brackets. We use fixação de precisão with multiple reference points to ensure accurate hole pattern locations.

Quality control ensures sensor mounts meet all positioning requirements. Inspeção CMM verifies mounting hole patterns, reference surface locations, and perpendicularity/parallelism of critical planes. Medição da planeza confirms sensor mounting surfaces meet specifications using precision indicators. We perform testes de adaptação with actual sensors when specified to verify proper seating and clearance. Every sensor mount receives dimensional reports, geometric tolerance verification, material certifications, and inspection documentation ensuring complete compliance with sensing system requirements and ISO quality standards.

Aplicações e casos de utilização

Precision-machined sensor mounts serve essential positioning functions across diverse automation applications:

- Machine Vision Systems: Camera mounting brackets, lighting fixtures, and lens housings for automated inspection, quality control, and robotic guidance

- Robótica industrial: Tool center point (TCP) sensor mounts, force sensor brackets, and vision sensor housings for robot end effectors

- Automated Inspection Equipment: Precision positioning mounts for laser scanners, measurement sensors, and coordinate measuring probes

- Máquinas de embalagem: Proximity sensor brackets, photoelectric sensor mounts, and vision system fixtures for product detection and verification

- Máquinas-ferramentas CNC: Tool breakage detection sensor mounts, probing system brackets, and measurement sensor fixtures

- Automatização de armazéns: Barcode scanner mounts, dimensioning system brackets, and laser sensor housings for sortation and identification

- Fabrico de semicondutores: Ultra-clean sensor mounts for wafer inspection, alignment sensors, and metrology equipment in clean room environments

Why Choose Yicen Precision for Sensor Mounts?

Yicen Precision specializes in sensor mounts CNC machining with lead times as short as 3-5 days for simple brackets and 1-2 weeks for complex adjustable mounting systems. Our flexible manufacturing supports both prototype development for new sensor integration (1-10 units) and production quantities from 25 to 500+ units for machine builders and system integrators.

Fornecemos apoio de engenharia abrangente, incluindo Consulta DFM to optimize mount designs for stability and manufacturability, material selection guidance for specific environments and weight requirements, and design recommendations for adjustment mechanisms when needed. Our quality documentation includes inspection reports with hole pattern verification, flatness measurements, material certifications, and traceability records supporting ISO 9001 compliance.

Our cost-effective approach leverages efficient machining strategies, optimized material utilization, and standardized processes to deliver competitive pricing. We understand sensor mounts directly impact measurement accuracy and system performance. Whether you’re building machine vision inspection systems, robotic workcells, or automated measurement equipment, our expertise ensures your sensor mounts deliver the stability and precision your applications demand. Contact us today for technical consultation and rapid quotes on your sensor mounts manufacturing requirements.