What is Automotive Prototyping?

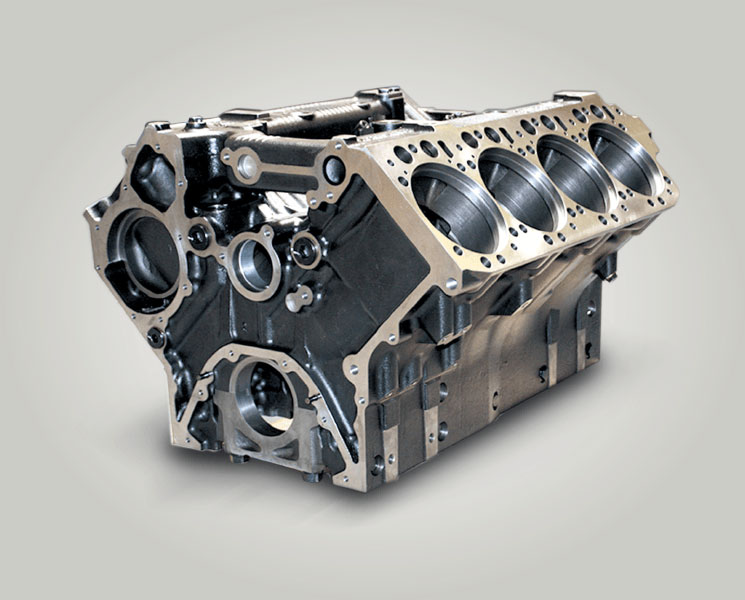

Automotive prototyping is the process of creating functional, testable components and assemblies from CAD designs to validate engineering concepts before mass production. Prototypes include everything from engine components and suspension parts to interior trim and electronic housings that replicate production geometry and material properties. Prototyping is used in R&D departments, design studios, racing teams, aftermarket companies, and OEM development centers. The critical function involves verifying dimensional accuracy, testing mechanical properties and durability, validating assembly processes and fitment, identifying design improvements and cost reductions, accelerating time-to-market through rapid iteration, and providing physical samples for presentations, investor meetings, and trade shows before committing to expensive production tooling and high-volume manufacturing.

Principais requisitos técnicos

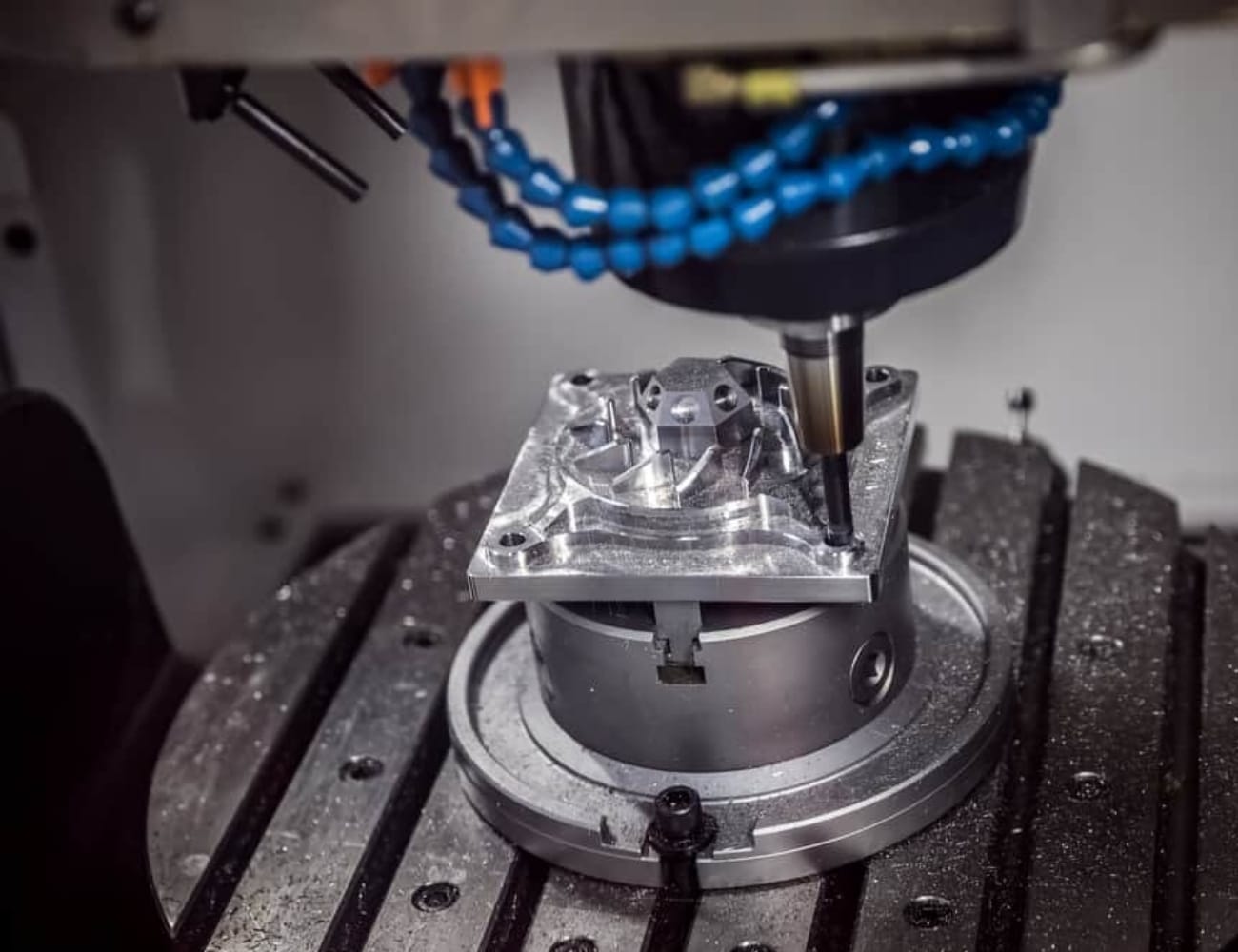

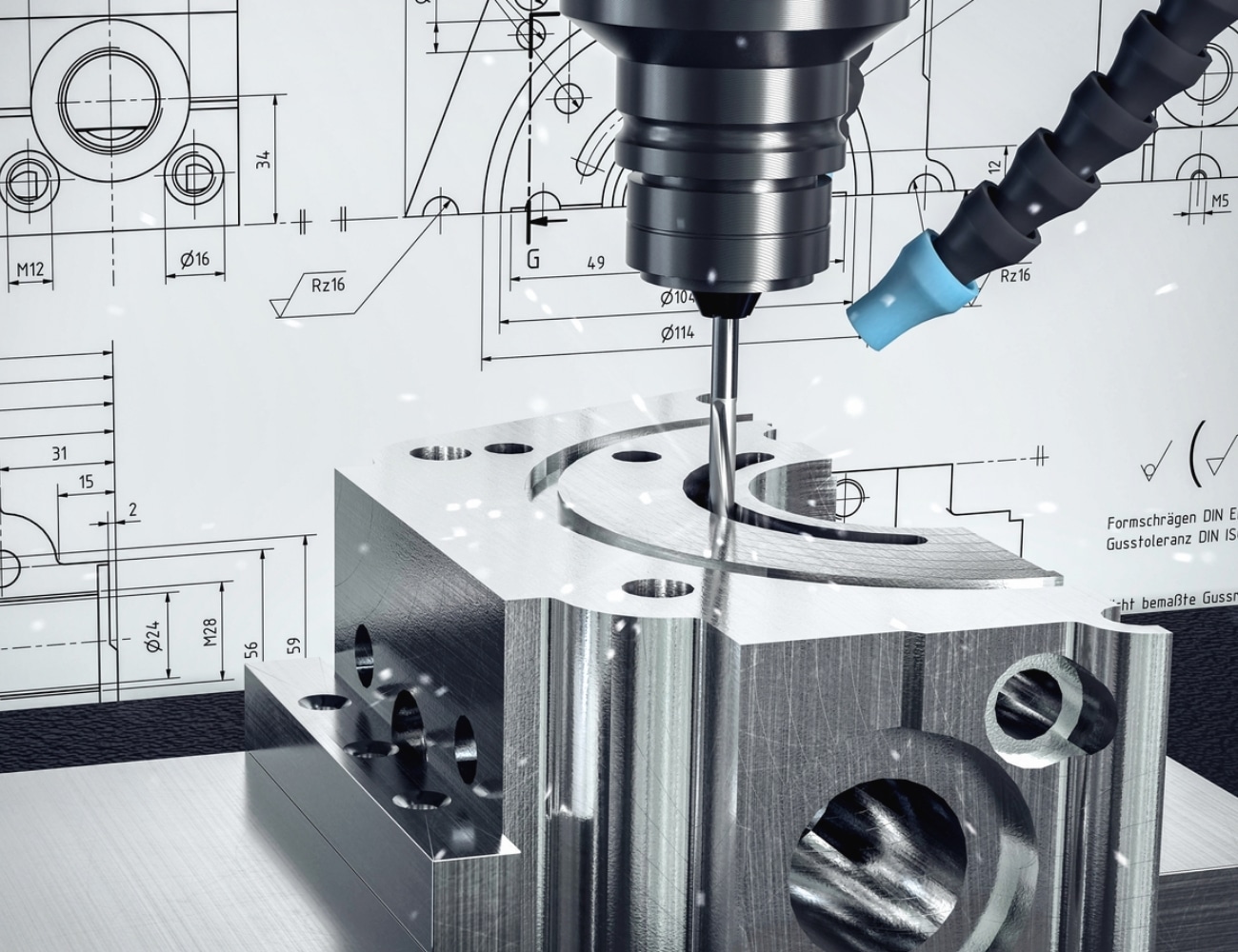

A maquinagem CNC de protótipos exige flexibilidade para acomodar alterações frequentes no design, mantendo a precisão ao nível da produção. As tolerâncias típicas variam entre ±0.002″ to ±0.005″ para protótipos funcionais, com tolerâncias mais apertadas de ±0.001″ available for critical features requiring final production accuracy. Material specifications must match intended production materials including aluminum alloys (6061, 7075), steel grades (4140, 4340), stainless steel (304, 316), engineering plastics (PEEK, Delrin), and specialty alloys. Surface finish requirements vary by application: functional surfaces need 32-63 Ra for proper assembly and movement, while cosmetic surfaces require 16-32 Ra for appearance validation. Documentation requirements include dimensional reports, material certifications, and as-built drawings. Prototypes must accurately represent production part performance for testing under real operating conditions including stress testing, thermal cycling, vibration analysis, and durability validation to ensure design readiness.

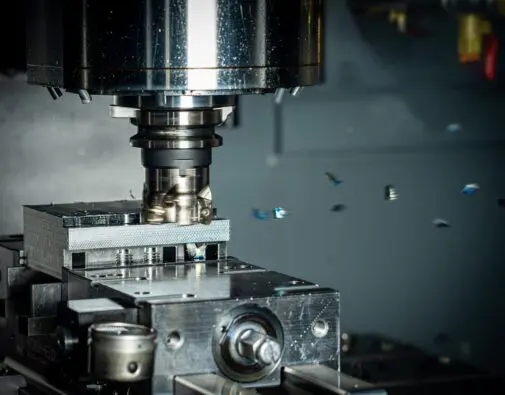

Desafios e soluções para o fabrico

Prototyping presents unique challenges including tight deadlines with minimal lead time, frequent design revisions requiring flexible programming, working from preliminary CAD models that may lack complete manufacturing details, balancing speed with accuracy for meaningful test results, and managing costs while using production-intent materials. Single-part or low-quantity runs lack economy of scale, making efficient machining strategies essential.

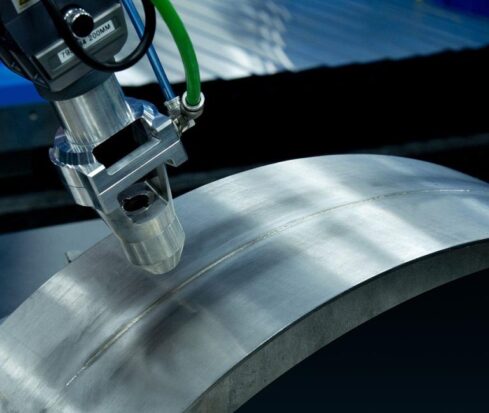

Yicen Precision overcomes these challenges with dedicated prototyping workflows optimized for quick turnarounds without sacrificing quality. Our advanced CAM software enables rapid programming from various CAD formats with automatic feature recognition. We maintain extensive tooling inventory eliminating delays from special tool orders. Experienced machinists can work from incomplete models, providing DFM feedback to designers. Priority scheduling ensures prototype projects receive immediate attention. Custom fixturing solutions adapt quickly to new geometries. Our quality control includes Inspeção CMM of critical dimensions, functional testing recommendations, and detailed documentation packages to support design validation and iteration decisions.

Aplicações e casos de utilização

Prototyping CNC machining serves diverse automotive development applications:

- New Vehicle Development – Prototype components for concept cars, new model development, and platform engineering across all vehicle systems

- Electric Vehicle Innovation – Battery enclosures, motor housings, thermal management components, and power electronics prototypes for EV development

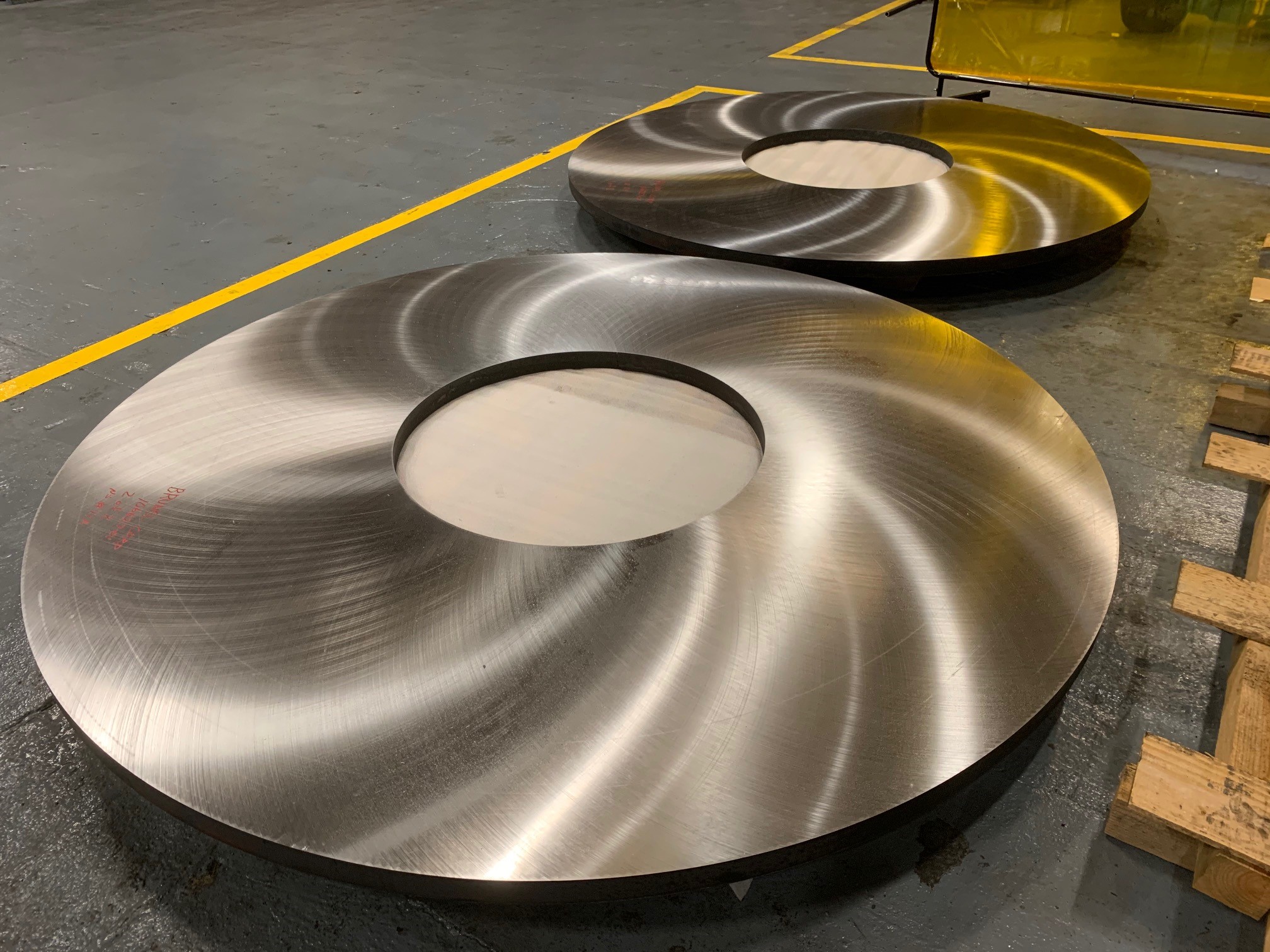

- Performance Engineering – Custom intake manifolds, turbo components, suspension upgrades, and drivetrain parts for performance testing and validation

- Autonomous Vehicle Systems – Sensor housings, mounting brackets, computing enclosures, and integration components for self-driving technology development

- Interior and Exterior Trim – Functional prototypes for dashboard components, door handles, trim pieces, and body panel fitment verification

- Aftermarket Product Development – Performance parts, accessory brackets, and custom components for market testing before production launch

- Racing and Motorsports – Quick-turn prototype parts for race teams needing immediate testing, validation, and competition-ready components

Porquê escolher a Yicen Precision para a criação de protótipos?

Yicen Precision specializes in fast-turnaround prototyping CNC machining with lead times as short as 2-5 days for simple parts and 1-2 weeks for complex assemblies. Our scalable approach supports single prototype parts for initial concept validation through low-volume pre-production runs of 25-100 units for extended testing. We provide comprehensive engineering support including Consulta DFM to optimize designs for both prototyping and future production, cost reduction recommendations, and alternative material suggestions. Complete documentation with inspection reports, material certifications, and digital records ensures traceability throughout development. Our cost-effective prototyping solutions leverage efficient programming, strategic material sourcing, and streamlined workflows that deliver production-quality parts at prototype speeds without compromising the accuracy and functionality your automotive development projects demand. Contact us today for technical consultation and rapid prototyping CNC machining quotes.