What are Suspension Components?

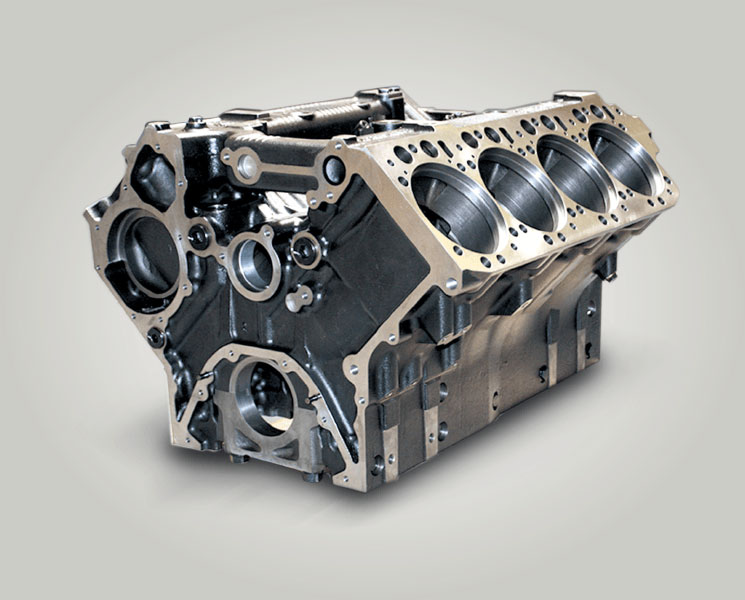

Suspension components are the mechanical linkages and mounting assemblies that connect vehicle wheels to the chassis while controlling motion and absorbing impacts. These parts include control arms, steering knuckles, suspension links, trailing arms, strut mounts, and camber plates that work together to maintain wheel alignment and vehicle stability. Suspension components are used in passenger cars, SUVs, commercial trucks, racing vehicles, off-road equipment, and heavy-duty transport applications. Their critical function involves maintaining proper wheel alignment geometry, transferring loads between wheels and chassis, absorbing road shocks and vibrations, enabling controlled suspension articulation, and ensuring predictable handling characteristics under acceleration, braking, and cornering forces.

Principais requisitos técnicos

Suspension components CNC machining demands exceptional precision for bushing bore alignment, ball joint taper angles, and mounting hole positioning. Typical tolerances range from ±0.002″ to ±0.005″ for critical features like pivot points, mounting surfaces, and alignment geometry. Material specifications include aluminum alloys (6061-T6, 7075) for lightweight performance, forged steel for heavy-duty applications, and chromoly steel for racing components. Surface finish requirements vary: bushing bores need 16-32 Ra for proper press-fit and bearing function, while mounting surfaces require 63-125 Ra for adequate bolt clamping. Ball joint taper angles must maintain ±0.25 degrees for proper retention. Suspension components must withstand dynamic loads exceeding 3,000 lbs, impact forces from road irregularities, operating temperatures from -40°F to 250°F, and resist fatigue, corrosion, and stress cracking throughout their service life.

Desafios e soluções para o fabrico

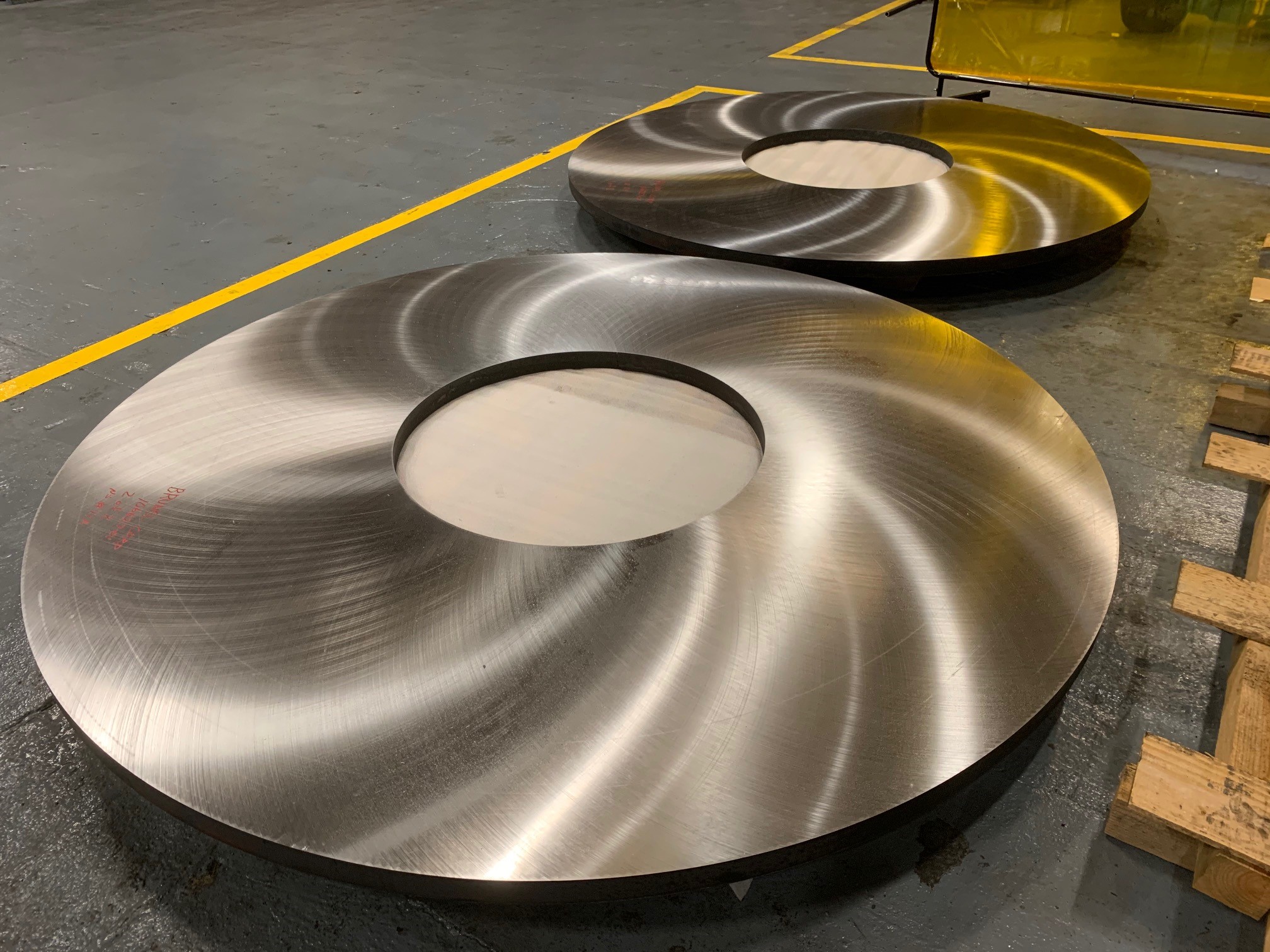

Machining suspension components presents significant challenges due to complex three-dimensional geometries, multiple angled features requiring precise orientation, thin-walled sections prone to deflection, and the need for exact bushing bore alignment across multiple pivot points. Material stress from forging processes can cause distortion during machining. Achieving proper ball joint taper angles while maintaining tight positional tolerances demands advanced fixturing and multi-axis capabilities.

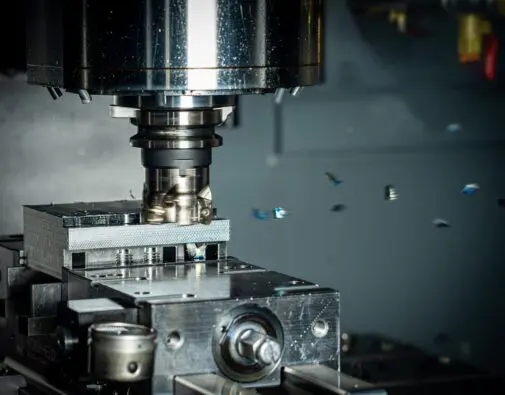

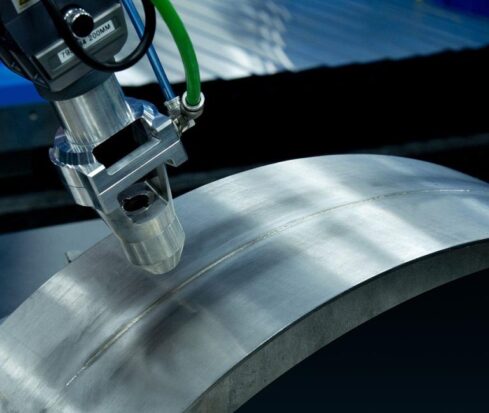

Yicen Precision overcomes these challenges with state-of-the-art 5-axis CNC machining centers that enable complete access to complex geometries and angled features in single setups. Our advanced CAM software optimizes tool paths to minimize deflection in thin-walled areas while maintaining dimensional accuracy. We utilize precision boring systems and angle heads for consistent bushing bore alignment and ball joint taper cutting. Stress-relieving procedures and controlled machining sequences prevent distortion in forged components. Custom fixtures provide rigid clamping at optimal locations without inducing stress. Our quality control includes comprehensive Inspeção CMM of all critical dimensions, taper angle verification using precision gauges, bore alignment measurement, and geometry validation against alignment specifications.

Aplicações e casos de utilização

Suspension components CNC machining serves diverse automotive and motorsport applications:

- Passenger Vehicle Production – Control arms, knuckles, and suspension links for sedans, SUVs, and crossovers in OEM manufacturing (Honda, Toyota, Mazda assemblies)

- High-Performance and Racing – Lightweight tubular control arms, adjustable suspension links, and custom knuckles for NASCAR, Formula racing, and track-day applications

- Commercial Truck and Heavy Equipment – Heavy-duty suspension components for Class 8 trucks, trailers, buses, and construction equipment with high load capacity

- Off-Road and 4×4 Vehicles – Reinforced suspension arms, lift kit components, and articulation links for Jeeps, trucks, and off-road racing vehicles

- Electric Vehicle Platforms – Optimized suspension geometry components for EV-specific chassis designs with battery packaging considerations

- Aftermarket Performance Upgrades – Adjustable control arms, camber kits, and upgraded suspension components for handling improvements and motorsport conversions

- Classic Vehicle Restoration – Reverse-engineered suspension components for vintage car rebuilds with modern geometry and improved durability

Why Choose Yicen Precision for Suspension Components?

Yicen Precision specializes in complex suspension components CNC machining with fast turnaround times from prototype development to full-scale production runs. Our scalable manufacturing capabilities support custom one-off racing components and high-volume OEM production with consistent dimensional accuracy and quality. We provide comprehensive engineering support including Consulta DFM to optimize geometry, reduce weight, and improve strength-to-weight ratios while maintaining proper suspension kinematics. Complete material traceability with certified mill test reports and documentation packages ensures compliance with automotive safety standards. Our cost-effective solutions leverage multi-axis machining efficiency, optimized material removal strategies, and automated inspection processes without compromising the precision and reliability your suspension component applications require. Contact us today for technical consultation and custom suspension components machining quotes.