Absolutely. We offer comprehensive reverse engineering services using 3D scanning and CAD modeling to recreate transmission housings for classic restorations, obsolete models, and custom conversion projects with improved design features.

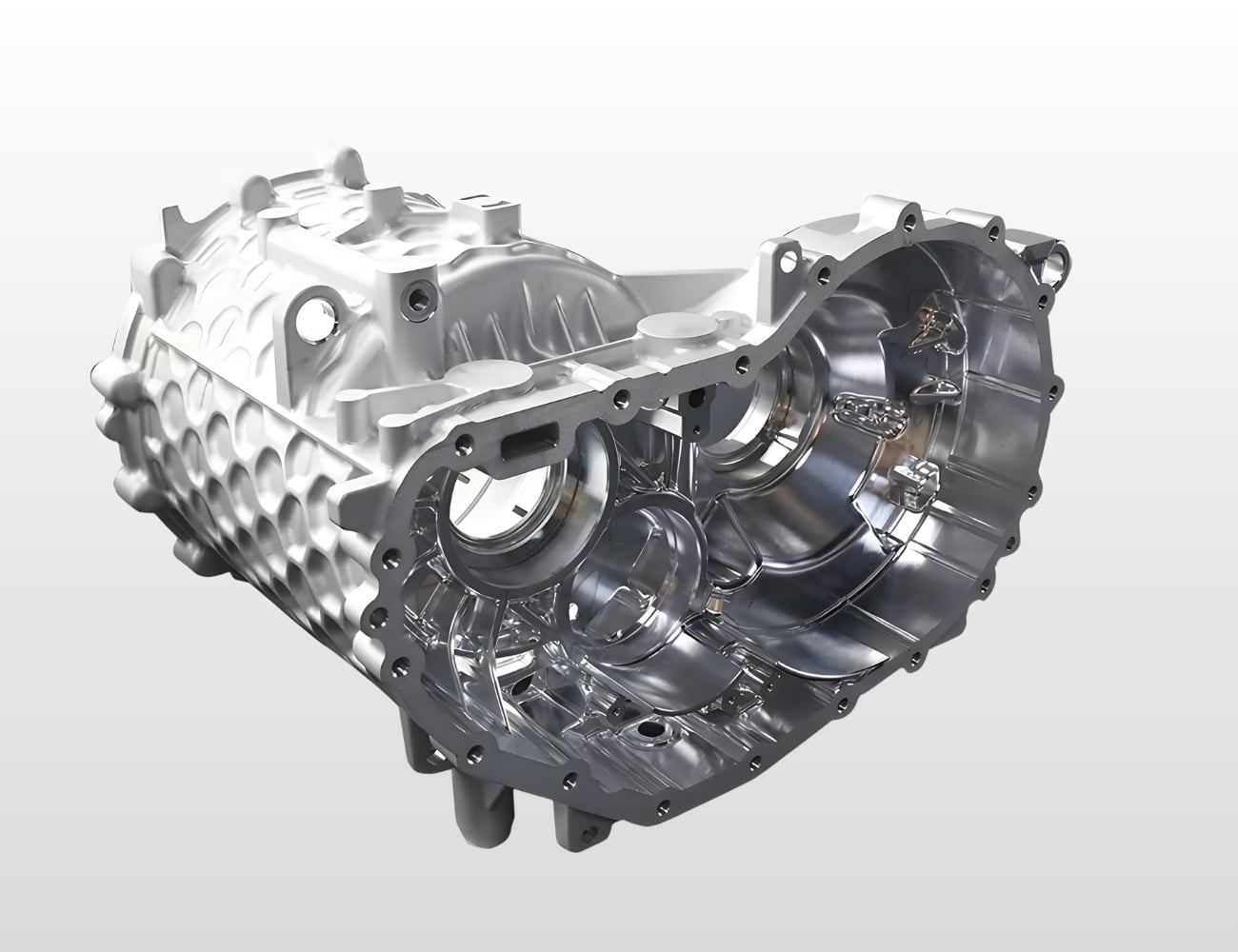

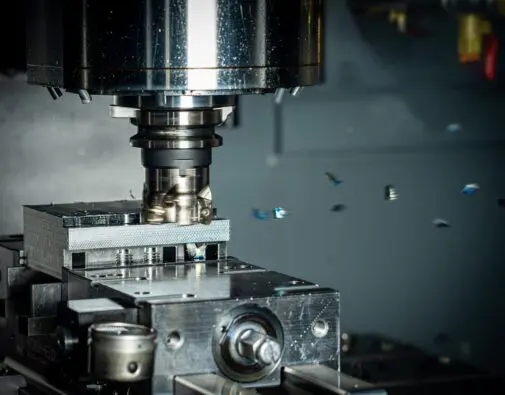

Precision-manufactured transmission housings engineered with advanced CNC technology for superior durability and exact fitment. Our automotive-grade machining ensures tight tolerances, complex geometries, and optimal bearing alignment for reliable power transmission. Get your custom transmission housings CNC machining quote today.

Os serviços de maquinação fornecem peças de alta precisão e prontas a produzir para a indústria automóvel, apoiando tudo, desde a criação de protótipos até ao fabrico em grande escala. Maquinamos componentes complexos com tolerâncias apertadas, optimizados para desempenho, durabilidade e repetibilidade ideais para motores, transmissões, chassis e montagens personalizadas. Quer esteja a construir veículos de alto desempenho ou sistemas eléctricos, as nossas capacidades CNC avançadas garantem que cada peça cumpre rigorosos padrões de qualidade e engenharia. Entre em contacto hoje para discutir as suas necessidades de maquinação automóvel e solicitar um orçamento gratuito.

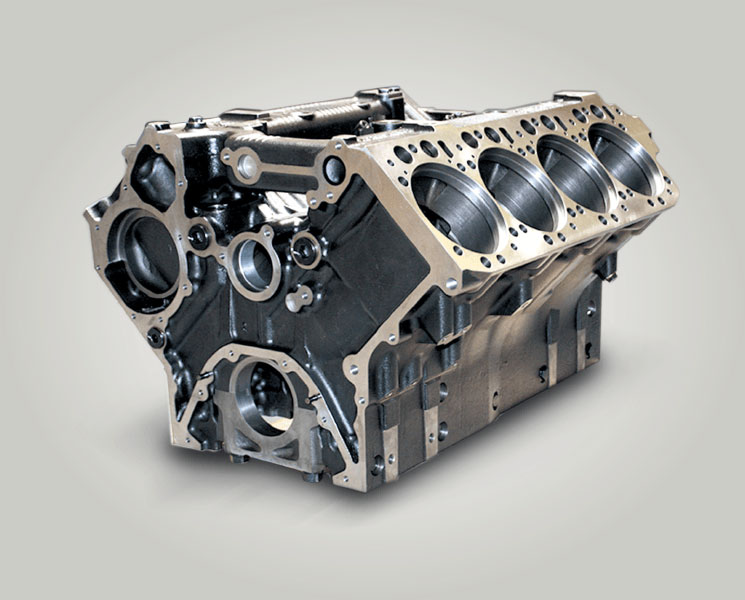

Transmission housings are essential structural components that protect internal gears, shafts, and synchronizers while maintaining precise bearing alignment and gear mesh patterns. These critical assemblies must provide rigid support, fluid containment, and accurate mounting interfaces for optimal drivetrain performance. Precision transmission housings CNC machining ensures proper gear alignment, minimal noise and vibration, and long-term reliability across manual, automatic, and dual-clutch transmission systems.

Yicen Precision delivers superior transmission housings CNC machining through advanced 5-axis milling centers and multi-axis lathes equipped with heavy-duty tooling systems. We machine transmission housings from aluminum alloys, magnesium, and cast iron with exceptional dimensional accuracy and complex internal features. Our ISO-compliant processes and stringent quality controls ensure every transmission housing meets exact specifications for bearing bore concentricity, mounting face flatness, and fluid sealing surfaces.

Desde protótipos de alto desempenho a peças prontas para produção, maquinamos componentes de precisão que cumprem os exigentes padrões do sector automóvel.

Fabrico CNC de alta precisão com tecnologia avançada e eficiência inigualável.

Produção CNC optimizada utilizando máquinas de última geração para uma qualidade consistente.

Fabrico e montagem especializados de componentes CNC complexos sob o mesmo teto.

Operações CNC totalmente automatizadas que permitem uma maquinação rápida, precisa e fiável.

Optimizado para fornecer peças CNC de qualidade superior com velocidade e precisão.

Fabrico CNC de ponta a ponta com fluxos de trabalho contínuos e resultados superiores.

Em Serviços de máquinas CNCA nossa empresa oferece materiais para automóveis de elevado desempenho, tais como ligas de alumínio, aços inoxidáveis, titânioe ligas de níquel. Estes materiais são concebidos para uma força superior, resistência ao calor e durabilidade, garantindo um desempenho ótimo para componentes automóveis críticos. Quer se trate de peças de motor, chassis ou sistemas de escape, a nossa maquinação de precisão garante a mais elevada qualidade para cada aplicação.

Em Serviços de máquinas CNC, oferecemos prémios acabamentos de superfície para automóveis como anodização, niquelageme revestimento em pó para melhorar a força, a resistência à corrosão e o aspeto. Os nossos acabamentos garantem que as suas peças automóveis são duradouras, fiáveis e estão prontas para aplicações exigentes.

A Yicen Precision serve um vasto espetro de indústrias, abrangendo a indústria aeroespacial, automóvel, eletrónica, médica e muito mais. Somos especializados no fornecimento de peças fiáveis e de alta qualidade, concebidas para responder aos desafios de engenharia únicos de cada indústria.

Veja porque é que os clientes confiam na Yicen Precision para a maquinagem CNC. Os nossos testemunhos destacam a satisfação com a precisão, a qualidade, a entrega atempada e o apoio dedicado, fomentando parcerias duradouras em todos os sectores a nível mundial.

A Yicen Precision forneceu-nos serviços de maquinagem CNC de primeira linha. A sua atenção ao pormenor e eficiência são inigualáveis.

Tempos de execução rápidos e maquinação precisa. A Yicen Precision fornece sempre trabalho de qualidade, a tempo e horas.

Serviço excecional e maquinação fiável. A Yicen Precision é o nosso fornecedor de referência para todos os projectos relacionados com CNC.

Óptima comunicação e excelente trabalho artesanal. A Yicen Precision cumpre sistematicamente as nossas exigentes especificações.

Somos especialistas em converter as suas ideias em componentes funcionais de alta qualidade, com uma velocidade e precisão sem paralelo. Com tecnologia avançada e perícia artesanal, criamos peças que cumprem as especificações mais complexas.

Transmission housings are essential structural components that protect internal gears, shafts, and synchronizers while maintaining precise bearing alignment and gear mesh patterns. These critical assemblies must provide rigid support, fluid containment, and accurate mounting interfaces for optimal drivetrain performance. Precision transmission housings CNC machining ensures proper gear alignment, minimal noise and vibration, and long-term reliability across manual, automatic, and dual-clutch transmission systems.

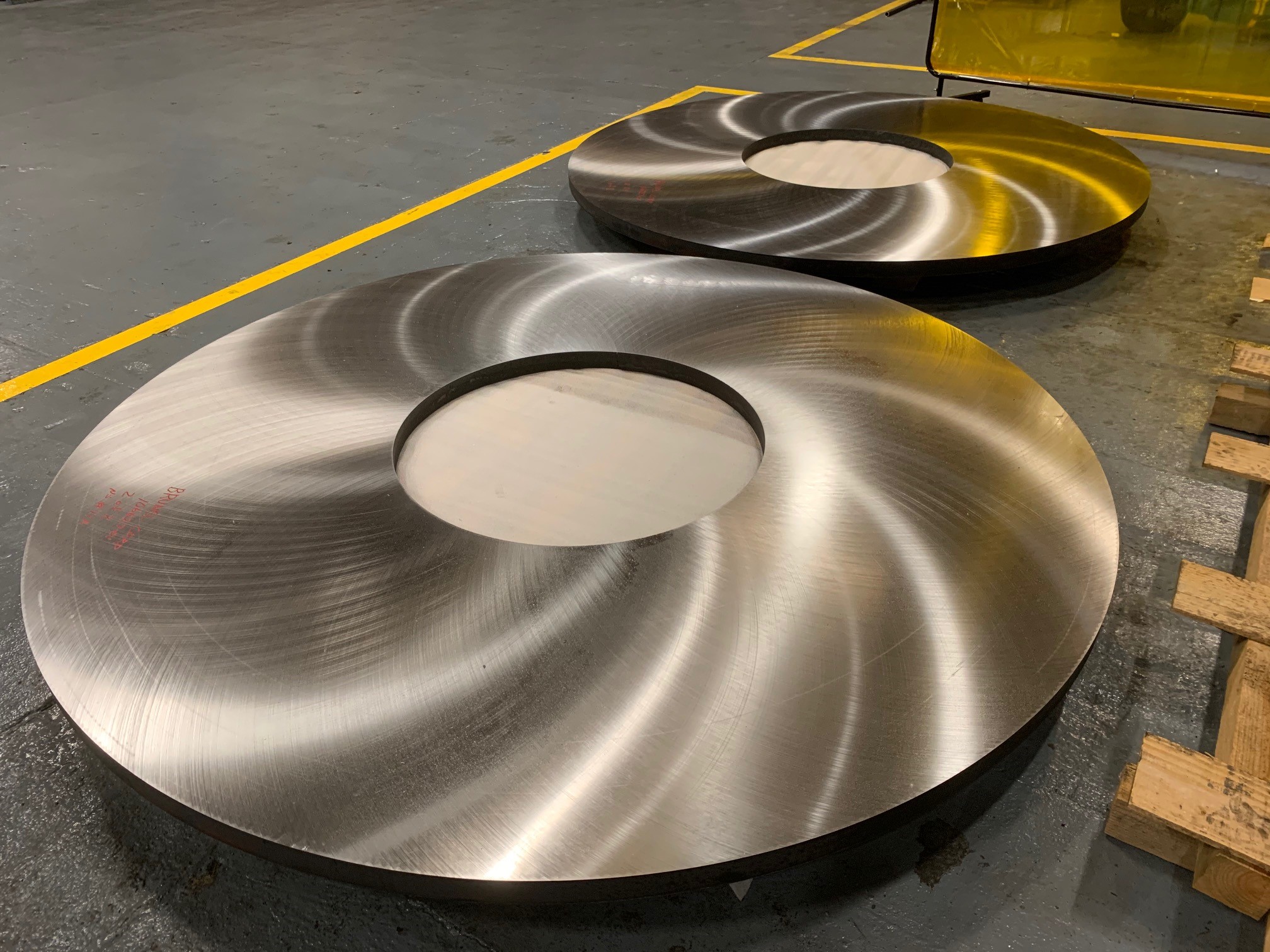

Yicen Precision delivers superior transmission housings CNC machining through advanced 5-axis milling centers and multi-axis lathes equipped with heavy-duty tooling systems. We machine transmission housings from aluminum alloys, magnesium, and cast iron with exceptional dimensional accuracy and complex internal features. Our ISO-compliant processes and stringent quality controls ensure every transmission housing meets exact specifications for bearing bore concentricity, mounting face flatness, and fluid sealing surfaces.

A transmission housing, also called a transmission case or gearbox housing, is the main structural enclosure that contains and supports all transmission components including gears, shafts, bearings, synchronizers, and hydraulic systems. It provides mounting surfaces for the engine, drivetrain, and vehicle chassis while maintaining proper alignment of rotating assemblies. Transmission housings are used in passenger vehicles, commercial trucks, heavy equipment, racing applications, and marine propulsion systems. Their critical function involves supporting bearing loads, containing transmission fluid, maintaining gear alignment, dissipating heat, and providing structural rigidity to ensure smooth power transfer from engine to wheels.

Transmission housings CNC machining demands exceptional precision for bearing bore alignment, mounting face flatness, and bolt hole positioning. Typical tolerances range from ±0,001″ a ±0,005″ for critical features like bearing bores, shaft centerlines, and mating surfaces. Material specifications include aluminum alloys (A380, 356) for lightweight passenger vehicles, magnesium alloys for performance applications, and cast iron or steel for heavy-duty commercial transmissions. Surface finish requirements vary: bearing bores need 16-32 Ra for proper bearing fit, while sealing surfaces require 32-63 Ra for gasket or seal compatibility. Mounting faces must maintain flatness within 0.002″ across the surface. Transmission housings must withstand torque loads exceeding 500 lb-ft, operating temperatures from -40°F to 300°F, vibration, fluid pressure, and resist corrosion from transmission fluid throughout their service life.

Machining transmission housings presents significant challenges due to large component size, complex internal cavities, multiple bearing bores requiring precise alignment, and thin-walled sections that can distort under cutting forces. Maintaining concentricity between input and output shaft bores while machining mounting surfaces and bolt patterns requires advanced fixturing and multi-axis capabilities. Cast material inconsistencies can cause dimensional variations and tool wear issues.

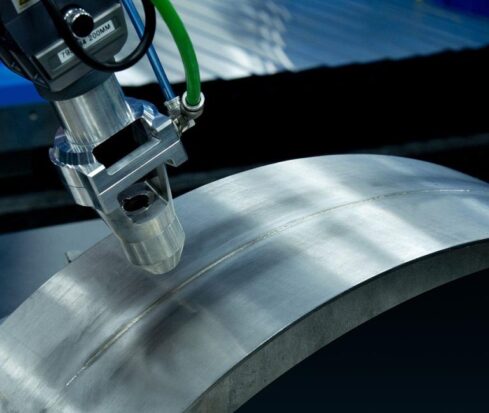

Yicen Precision overcomes these challenges with state-of-the-art 5-axis CNC machining centers featuring extended work envelopes and rigid construction for large housing components. Our advanced CAM software optimizes tool paths to minimize deflection in thin-walled areas while maintaining tight tolerances. We utilize precision line boring systems and custom tooling to achieve consistent bearing bore alignment and concentricity across multiple bores. Temperature-controlled facilities prevent thermal expansion during machining operations. Heavy-duty fixtures provide stable clamping without inducing stress or distortion. Our quality control includes comprehensive Inspeção CMM of all critical dimensions, bore alignment verification using laser measurement systems, and flatness checks on mounting surfaces.

Transmission housings CNC machining serves diverse automotive and industrial applications:

Yicen Precision specializes in complex transmission housings CNC machining with fast turnaround times from prototype development to full-scale production runs. Our scalable manufacturing capabilities support custom low-volume projects and high-volume OEM production with consistent dimensional accuracy and quality. We provide comprehensive engineering support including Consulta DFM to optimize rib structures, wall thickness, and mounting configurations for strength and manufacturability. Complete material traceability with certified mill test reports and documentation packages ensures compliance with automotive industry standards. Our cost-effective solutions leverage multi-axis machining efficiency, optimized material removal strategies, and automated inspection processes without compromising the precision and reliability your transmission housing applications require. Contact us today for technical consultation and custom transmission housings machining quotes.

Explorar Serviços de maquinagem para obter informações especializadas sobre maquinagem CNC, tendências da indústria, sugestões de fabrico e actualizações tecnológicas - concebidas para o manter informado, inspirado e na vanguarda da engenharia de precisão.

Do you provide reverse engineering for discontinued transmission housings?

Absolutely. We offer comprehensive reverse engineering services using 3D scanning and CAD modeling to recreate transmission housings for classic restorations, obsolete models, and custom conversion projects with improved design features.

Can you handle both prototype and production transmission housings?

Yes, we support complete development cycles from single prototype transmission housings for testing and validation to production runs of thousands of units. Our flexible machining systems scale efficiently while maintaining consistent quality across all volumes.

Which materials do you machine for transmission housings?

We machine aluminum alloys (A380, 356, 6061), magnesium alloys for lightweight applications, cast iron, and steel for heavy-duty transmissions. Material selection depends on torque capacity, weight requirements, thermal properties, and cost considerations.

What tolerances can you achieve for bearing bore alignment in transmission housings?

We routinely achieve bearing bore concentricity and alignment tolerances of ±0.001″ to ±0.002″ between input and output shafts. Our precision line boring and laser verification systems ensure accurate shaft centerline alignment critical for proper gear mesh and minimal vibration.