What is a Turbocharger Housing?

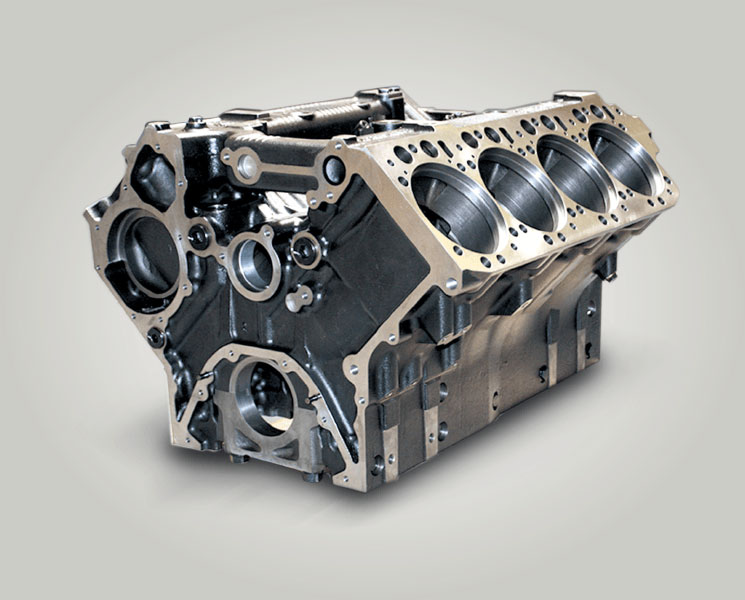

A turbocharger housing consists of two main components: the turbine housing that channels hot exhaust gases to spin the turbine wheel, and the compressor housing that directs compressed intake air to the engine. These housings include bearing housings, mounting flanges, wastegate ports, and oil/coolant passages. Turbocharger housings are used in passenger cars, diesel trucks, performance vehicles, marine engines, and industrial equipment. Their critical function involves optimizing exhaust gas flow to the turbine, managing compressed air delivery to the intake manifold, supporting bearing systems for the rotating assembly, withstanding exhaust temperatures exceeding 1,800°F, containing boost pressures up to 50 psi, and maintaining structural integrity through constant thermal cycling and vibration throughout demanding forced induction operation.

Principais requisitos técnicos

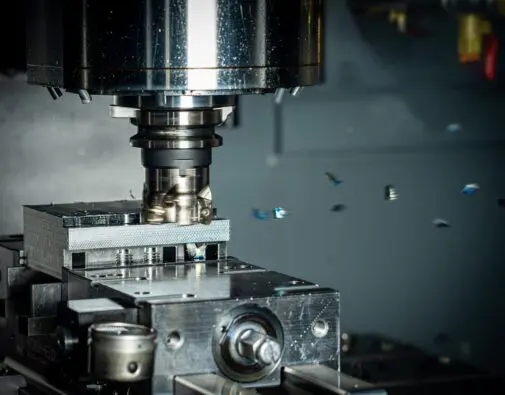

Turbocharger housings CNC machining requires extreme precision for bearing bore alignment, flange flatness, and internal flow path geometry. Typical tolerances range from ±0.001″ to ±0.003″ for critical features like bearing bores, mounting flanges, and mating surfaces. Material specifications include aluminum alloys (A356, 6061) for compressor housings, cast iron and ductile iron for turbine housings, stainless steel (304, 316) for high-temperature applications, and Inconel for extreme performance turbos. Surface finish requirements are critical: bearing bores need 16-32 Ra for proper bearing retention and oil sealing, while internal flow passages require 32-63 Ra for optimal aerodynamic efficiency and minimal turbulence. Flange surfaces must maintain flatness within 0.002″ across the surface for proper gasket sealing. Turbocharger housings must withstand exhaust temperatures exceeding 1,800°F, boost pressures up to 50 psi, thermal shock from rapid temperature changes, vibration from shaft rotation at 200,000+ RPM, and resist oxidation, thermal fatigue, and corrosion throughout their service life.

Desafios e soluções para o fabrico

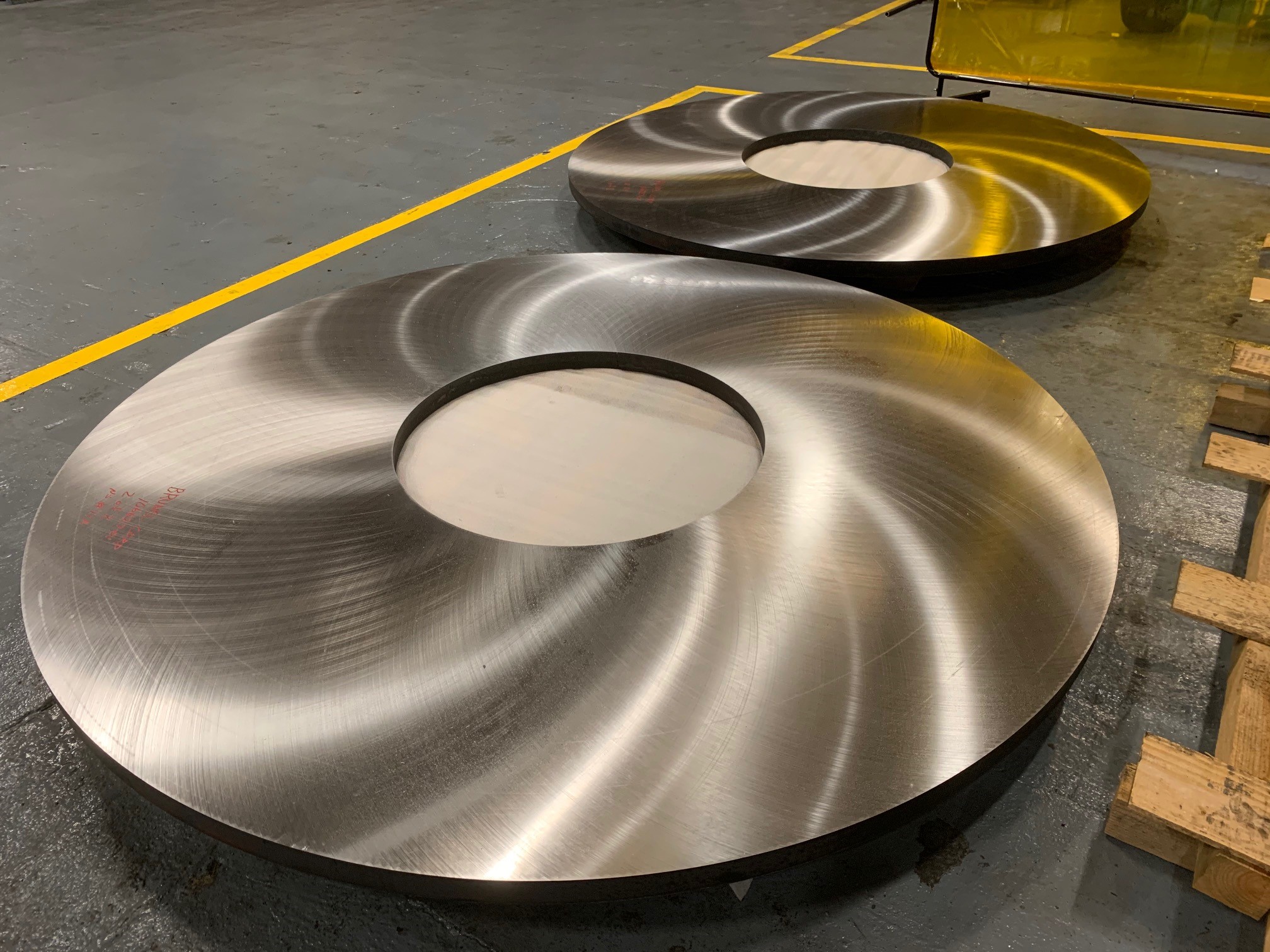

Machining turbocharger housings presents significant challenges due to complex spiral geometries in turbine and compressor volutes, thin-walled sections prone to distortion, the need for smooth internal surfaces for optimal flow, and maintaining tight tolerances on bearing bores while working with heat-resistant materials. High-temperature alloys like Inconel cause extreme tool wear. Achieving proper scroll geometry and surface finish while preventing distortion from clamping forces requires specialized approaches.

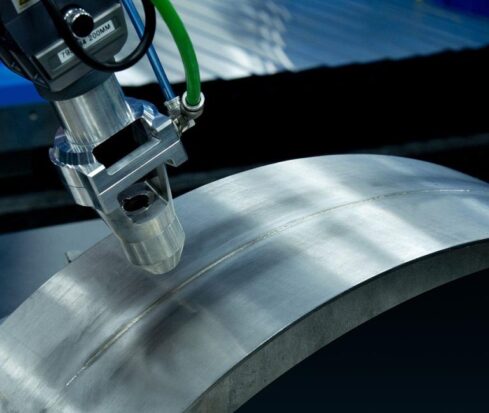

Yicen Precision addresses these challenges using state-of-the-art 5-axis CNC machining centers that enable complete access to complex spiral geometries and internal features without multiple setups. Our advanced CAM software creates optimized tool paths for smooth surface transitions in scroll areas while controlling cutting forces. We utilize specialized high-temperature tooling and ceramic inserts for machining Inconel and stainless steel components. Ball nose and tapered endmills achieve smooth internal contours with minimal step-over marks. Temperature-controlled machining environments and strategic cooling prevent thermal distortion. Custom soft-jaw fixtures provide secure clamping without deforming thin-walled sections. Our quality control measures include comprehensive Inspeção CMM of all critical dimensions, bearing bore concentricity verification, flange flatness measurement with precision surface plates, and internal surface finish validation using profilometers.

Aplicações e casos de utilização

Turbocharger housings CNC machining serves diverse automotive and industrial applications:

- Passenger Vehicle Production – OEM turbocharger housings for turbocharged sedans, hatchbacks, and compact cars (Ford EcoBoost, VW TSI, BMW assemblies)

- Diesel Truck Applications – Heavy-duty turbocharger housings for commercial trucks, agricultural equipment, and construction machinery with large displacement engines

- High-Performance and Racing – Custom turbocharger housings for drag racing, road racing, time attack, and street performance builds with optimized A/R ratios

- Marine Propulsion Systems – Corrosion-resistant turbocharger housings for diesel marine engines in commercial fishing, tugboats, and high-performance boats

- Industrial Power Generation – Turbocharger housings for stationary diesel generators, pump systems, and industrial compression equipment

- Aftermarket Performance Upgrades – Custom compressor and turbine housings for turbo upgrades, hybrid turbo conversions, and boost optimization projects

- Electric Vehicle Range Extenders – Small turbocharger housings for compact range-extender engines in plug-in hybrid and series hybrid platforms

Why Choose Yicen Precision for Turbocharger Housings?

Yicen Precision specializes in complex turbocharger housings CNC machining with industry-leading turnaround times for both prototype development and production volumes. Our scalable manufacturing capabilities support custom one-off racing turbo housings and high-volume OEM production with consistent dimensional accuracy and flow optimization. We provide comprehensive engineering support including Consulta DFM to optimize scroll geometry, A/R ratios, wall thickness, and thermal expansion considerations for maximum boost efficiency. Complete material traceability with certified mill test reports and heat treatment documentation ensures compliance with automotive and marine industry standards. Our cost-effective solutions leverage 5-axis machining efficiency, specialized tooling for difficult materials, and automated inspection processes without compromising the precision and thermal reliability your turbocharger housing applications demand. Contact us today for technical consultation and custom turbocharger housings machining quotes.