A. What are Audio Equipment Parts?

Audio equipment parts are precision-machined components that form the structural, acoustic, and functional elements of sound reproduction and recording devices. These components include headphone ear cup housings, speaker driver frames and baskets, amplifier chassis and heat sink enclosures, microphone bodies and grilles, mixing console faceplates, connector housings for audio interfaces, volume knobs and control dials, mounting brackets for studio monitors, and acoustic waveguides for sound shaping. They are essential in consumer headphones, professional studio monitors, home theater speakers, portable Bluetooth speakers, guitar amplifiers, DJ equipment, podcasting microphones, and high-fidelity audio systems.

The critical functions of audio equipment parts include providing rigid mounting for transducers to prevent unwanted vibrations, shaping acoustic properties through carefully designed chambers and ports, shielding sensitive electronics from electromagnetic and radio frequency interference, dissipating heat from power amplification circuits, and delivering premium aesthetics that reflect audio quality. Their precision directly impacts frequency response accuracy, harmonic distortion levels, signal integrity, and overall listening experience.

B. Principais requisitos técnicos

Manufacturing audio equipment parts requires meticulous attention to acoustic, mechanical, and aesthetic specifications. Dimensional tolerances for driver mounting surfaces typically range from ±0.005″ to ±0.010″ to ensure proper alignment and airtight sealing that prevents acoustic leakage affecting bass response. Concentricity tolerances for cylindrical components often require 0.003″ TIR or better to maintain acoustic symmetry and balanced sound reproduction.

Material specifications must consider acoustic properties including resonant frequencies, damping characteristics, and vibration transmission. Aluminum alloys provide excellent stiffness-to-weight ratios with natural damping properties ideal for speaker enclosures and headphone housings. Brass offers superior density and acoustic mass for microphone bodies and high-end component housings. Engineering plastics like ABS and polycarbonate provide design flexibility with good acoustic isolation properties.

Surface finish requirements vary by application, with speaker grilles requiring smooth surfaces with Ra values below 63 microinches for aesthetic appeal, while internal acoustic chambers may specify textured surfaces to reduce standing waves. Threaded features for driver mounting and assembly require precise pitch control within ±0.002″ and smooth operation to prevent damage during assembly. Wall thickness specifications must balance acoustic rigidity with weight optimization, typically ranging from 0.080″ to 0.250″ depending on material and size.

Acoustic port and vent geometries demand precise dimensional control to achieve target tuning frequencies, with diameter tolerances within ±0.010″ and length accuracy within ±0.020″. EMI shielding features require conductive surface treatments and precision-ground mating surfaces for effective electromagnetic isolation. Aesthetic requirements include flawless surface finishes free from visible tool marks, scratches, or blemishes that would detract from premium product appearance.

C. Desafios e soluções para o fabrico

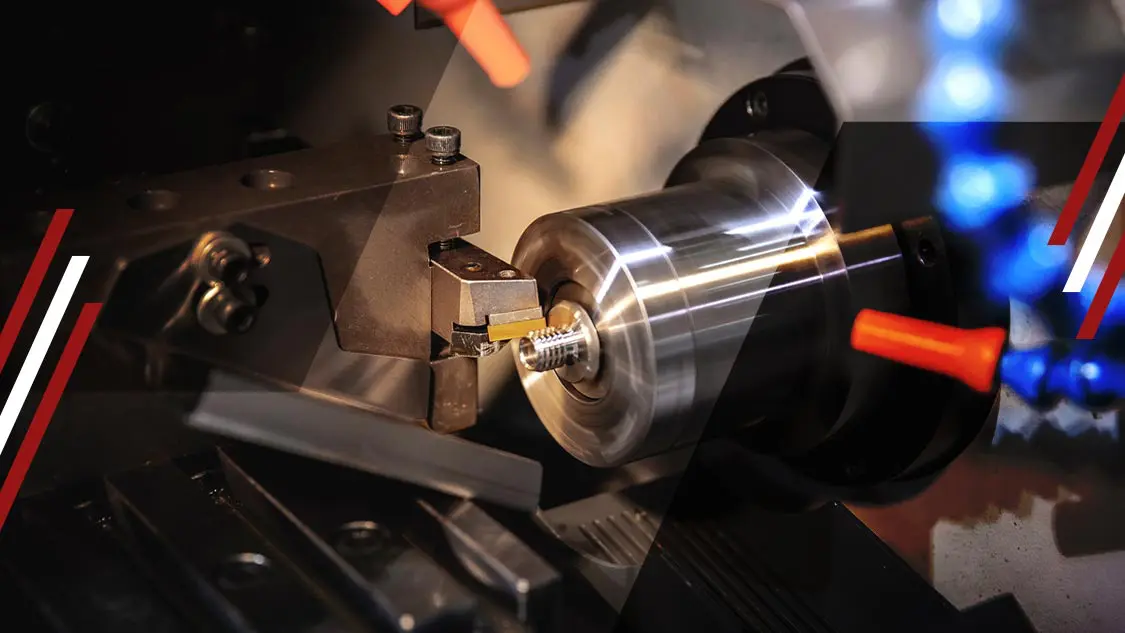

Machining audio equipment parts presents unique challenges including maintaining dimensional accuracy on thin-walled acoustic chambers susceptible to vibration and distortion, producing complex internal geometries for acoustic tuning without compromising structural integrity, and achieving premium surface finishes on visible components. Material variations like aluminum’s tendency toward surface imperfections or plastic’s susceptibility to melting require specialized approaches. Acoustic port machining demands precise diameter control and smooth internal surfaces to prevent turbulence that could introduce noise.

Yicen Precision overcomes these challenges through strategic manufacturing methodologies tailored to audio component requirements. Our 5-axis CNC machining centers enable complete machining of complex audio equipment parts in single setups, maintaining geometric relationships critical for acoustic performance while minimizing handling-induced errors. Advanced workholding fixtures specifically designed for thin-walled audio components distribute clamping forces evenly, preventing distortion during machining operations.

For premium surface finishes on visible components, we employ high-speed machining with optimized cutting parameters, sharp tooling, and flood coolant systems that produce mirror-like surfaces directly from machining operations. Secondary finishing operations including bead blasting, anodizing preparation, and polishing protocols ensure consistent aesthetic quality. Internal acoustic chambers are machined using specialized long-reach tooling with vibration-dampening characteristics that maintain dimensional accuracy.

Acoustic port machining utilizes precision boring operations with carbide tooling that produces smooth internal surfaces and precise diameter control. Our CAM programming incorporates helical interpolation strategies for circular features, minimizing tool pressure and improving dimensional consistency. Climate-controlled manufacturing environments prevent thermal expansion that could affect acoustic tuning dimensions.

Quality control includes comprehensive CMM inspection of critical mounting surfaces and acoustic dimensions, optical profilometry for surface finish verification, and acoustic measurement validation for tuned port components. Concentricity verification ensures symmetric sound radiation patterns. Assembly validation confirms proper fit of mating components and fastener engagement without acoustic leakage.

D. Aplicações e casos de utilização

Precision-machined audio equipment parts enable superior sound quality across diverse consumer electronics and professional audio applications:

- Premium Headphones and Earphones: Aluminum ear cup housings, driver mounting rings, adjustment mechanisms, and protective grilles for over-ear and in-ear audio devices

- Hi-Fi Speakers and Studio Monitors: Driver baskets, waveguides, phase plugs, binding post terminals, and acoustic port tubes for accurate sound reproduction

- Portable Bluetooth Speakers: Compact enclosures with integrated passive radiators, protective grilles, and mounting brackets for outdoor and travel audio

- Guitar and Bass Amplifiers: Chassis enclosures, heat sink assemblies, control panel faceplates, and corner protectors for stage and studio amplification

- Mixing Consoles and Audio Interfaces: Precision faceplates, rack mount brackets, knob assemblies, and connector housings for recording equipment

- Microphones and Recording Equipment: Microphone bodies, shock mount components, windscreen frames, and XLR connector housings for vocal and instrument capture

- Home Theater Systems: Subwoofer enclosures, satellite speaker housings, center channel brackets, and acoustic tuning components for immersive audio experiences

E. Why Choose Yicen Precision for Audio Equipment Parts?

Yicen Precision stands as your premier manufacturing partner for audio equipment parts CNC machining through our deep understanding of acoustic requirements and precision manufacturing expertise. Our rapid prototyping services deliver functional audio component prototypes within days, enabling acoustic testing, fit validation, and iterative design refinement before committing to production tooling and finishes.

We offer flexible scalability from boutique audio products requiring limited production runs through mass-market consumer electronics demanding high-volume manufacturing, maintaining acoustic precision and aesthetic quality regardless of order quantity. Our engineering team provides expert DFM consultation specifically focused on audio applications, optimizing designs for acoustic performance, manufacturing efficiency, and cost-effectiveness while preserving sound quality objectives.

Complete material traceability with certified documentation supports quality audits and compliance requirements for professional audio equipment. Our cost-effective solutions leverage efficient machining strategies, optimized material utilization, and process refinement that deliver superior audio equipment parts at competitive pricing without compromising the precision, acoustic properties, or premium aesthetics your products demand.

With dedicated project management, transparent communication throughout development and production phases, and commitment to on-time delivery, we become your trusted manufacturing partner for bringing exceptional audio products to market that delight listeners and exceed performance expectations.