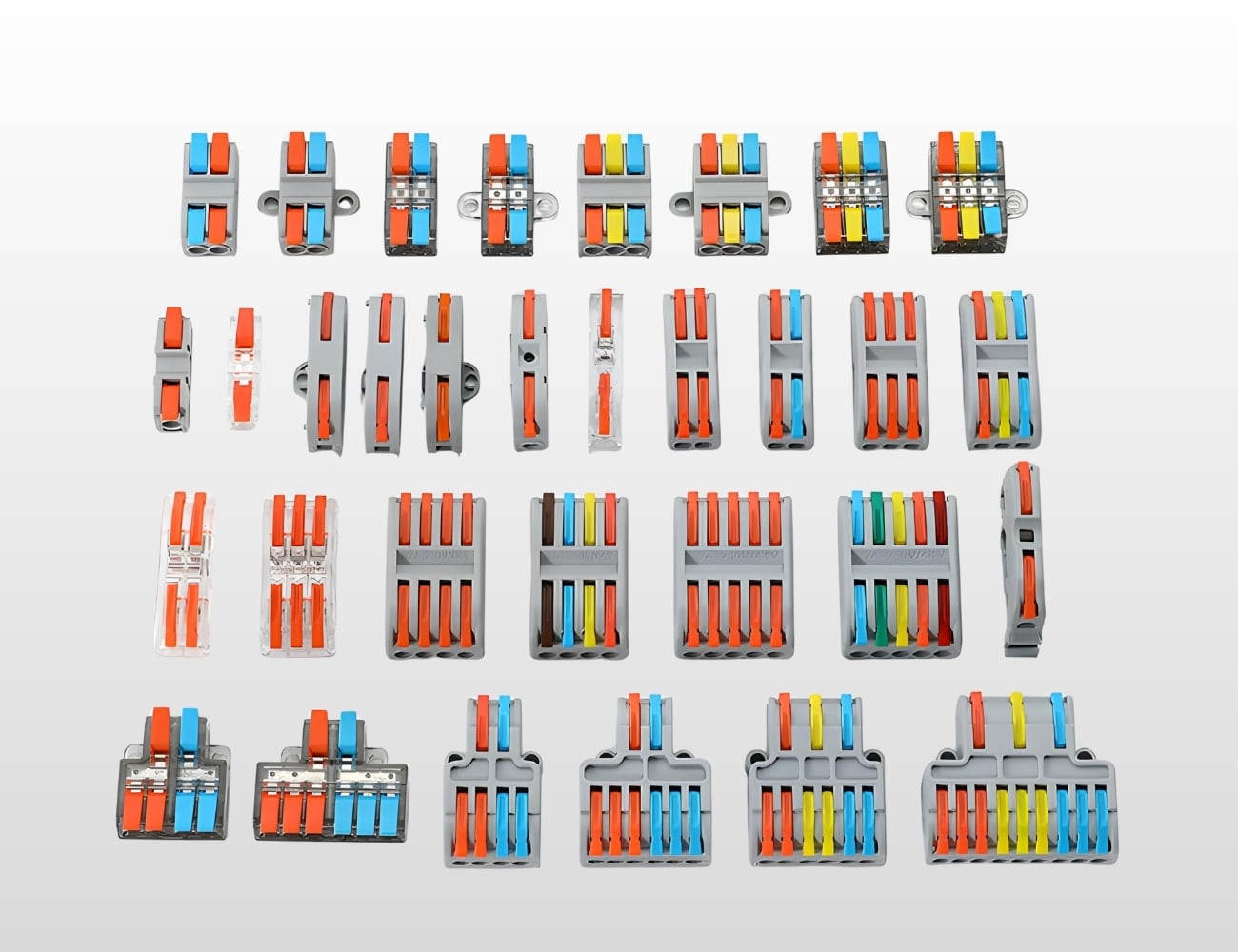

What are Connectors and Ports?

Connectors and ports are precision-engineered interface components that enable electrical, data, and power connections between electronic devices and peripherals. In consumer electronics, these components serve as gateways for charging, data transfer, audio/video output, and peripheral connectivity. They are used extensively across smartphones, tablets, laptops, gaming consoles, audio equipment, and smart home devices. Critical to device functionality, connectors and ports must withstand thousands of insertion cycles while maintaining electrical integrity, signal quality, and physical durability. Their design directly impacts user experience, device reliability, and overall product longevity in competitive consumer markets.

Principais requisitos técnicos

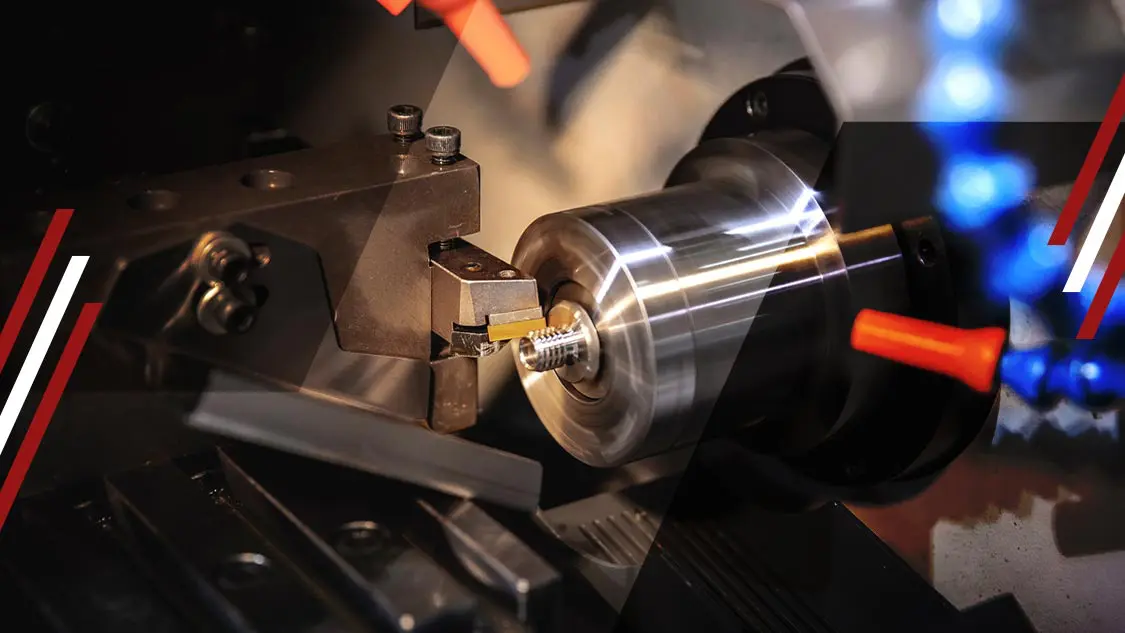

Manufacturing connectors and ports for consumer electronics demands exceptional precision and consistency. Typical tolerances range from ±0.001″ to ±0.0005″ for critical mating surfaces, contact points, and alignment features to ensure proper connectivity and prevent signal degradation. Material specifications must balance electrical conductivity, mechanical strength, and corrosion resistance—copper alloys for contact pins, stainless steel for housings, and specialized plastics for insulation components. Surface finish requirements are stringent, with Ra values often below 32 microinches to facilitate smooth insertion, reduce friction, and enhance aesthetic appeal. Components must withstand mechanical stress from repeated mating cycles, typically rated for 5,000 to 10,000 insertions depending on application. Environmental resistance is critical, requiring protection against moisture, dust, temperature fluctuations, and electromagnetic interference to maintain signal integrity and prevent premature failure in diverse operating conditions.

Desafios e soluções para o fabrico

Machining connectors and ports presents unique challenges including intricate geometries with multiple small features, thin walls susceptible to distortion, and precise alignment requirements across multiple components. The combination of different materials in assemblies—conductive metals for contacts and insulating plastics for housings—requires specialized tooling strategies. Maintaining dimensional consistency across high-volume production runs while achieving microscopic tolerances demands advanced process control.

Yicen Precision overcomes these challenges through strategic deployment of 5-axis CNC machining centers that access complex geometries in single setups, minimizing repositioning errors and improving accuracy. Our advanced CAM software optimizes tool paths for delicate features, while precision micro-tooling enables machining of fine details without compromising structural integrity. We employ specialized workholding fixtures designed for thin-walled components to prevent distortion during machining operations.

Our quality control measures include comprehensive CMM inspection of critical dimensions, automated optical inspection for surface defects, and electrical continuity testing for conductive components. Dimensional verification occurs at multiple production stages, with statistical process control ensuring consistency across batches. This integrated approach delivers connectors and ports that meet the exacting standards of leading consumer electronics manufacturers.

Aplicações e casos de utilização

Precision-machined connectors and ports serve critical roles across diverse consumer electronics applications:

- Smartphone and Tablet Charging Ports: USB-C, Lightning, and proprietary charging interfaces requiring durability and precision

- Laptop and Desktop Computer Connections: HDMI, DisplayPort, USB, Thunderbolt, and Ethernet ports for data and display connectivity

- Audio Equipment Interfaces: 3.5mm jacks, XLR connectors, and digital audio ports for headphones, speakers, and professional audio gear

- Wearable Device Charging Connectors: Magnetic and pogo pin charging interfaces for smartwatches and fitness trackers

- Gaming Console Ports: Controller connections, HDMI outputs, and proprietary gaming peripheral interfaces

- Smart Home Device Connectors: Power and data ports for IoT devices, security cameras, and home automation hubs

- Camera and Drone Interfaces: Memory card slots, USB connections, and charging ports for professional and consumer imaging devices

Why Choose Yicen Precision for Connectors and Ports?

Yicen Precision delivers unmatched advantages for connectors and ports CNC machining through our specialized capabilities and customer-focused approach. Our rapid turnaround times accelerate your product development cycle, with prototype parts delivered within days and production runs scaled efficiently to meet market demands. We offer seamless scalability from initial prototypes through high-volume production, maintaining consistent quality regardless of order size.

Our engineering team provides comprehensive DFM consultation, optimizing your designs for manufacturability while preserving functionality and aesthetics. We ensure complete material traceability with certified documentation for every component, meeting industry compliance requirements and facilitating quality audits. Our cost-effective solutions leverage efficient machining strategies and material optimization without compromising the precision or durability your connectors and ports demand.

With dedicated project management, real-time communication, and flexible production scheduling, we become an extension of your engineering team, committed to delivering connectors and ports that enhance your products’ performance and reliability.