A. O que é a prototipagem na eletrónica de consumo?

A prototipagem em eletrónica de consumo é o processo de criação de representações físicas e funcionais de concepções de produtos para validação, teste e aperfeiçoamento antes da produção em massa. Estes protótipos tangíveis incluem modelos de aparência que mostram o design industrial e a estética, protótipos funcionais que demonstram o funcionamento mecânico e a montagem, protótipos de engenharia para testes de durabilidade e desempenho, protótipos de pré-produção que validam os processos de fabrico e protótipos de apresentação para reuniões de investidores e feiras comerciais. A prototipagem é essencial em todas as categorias de produtos electrónicos de consumo, incluindo smartphones, tablets, wearables, equipamento áudio, dispositivos domésticos inteligentes, periféricos de jogos e produtos IoT.

As principais finalidades da prototipagem incluem a validação da intenção do design industrial e da ergonomia através da interação física, o teste da funcionalidade mecânica, incluindo a sensação dos botões, o funcionamento das dobradiças e as sequências de montagem, a verificação do encaixe dos componentes electrónicos e do desempenho da gestão térmica, a realização de estudos sobre a experiência do utilizador e avaliações de grupos de discussão, a identificação de desafios de fabrico e a conceção de melhorias no fabrico, a demonstração de conceitos de produtos às partes interessadas e a potenciais clientes e a aceleração dos ciclos de desenvolvimento através de uma iteração rápida baseada em feedback do mundo real. A prototipagem eficaz reduz os custos de desenvolvimento ao detetar atempadamente os problemas de conceção, minimiza o risco de produção ao validar as abordagens de fabrico e reduz o tempo de colocação no mercado, permitindo lançamentos de produtos mais rápidos.

B. Principais requisitos técnicos

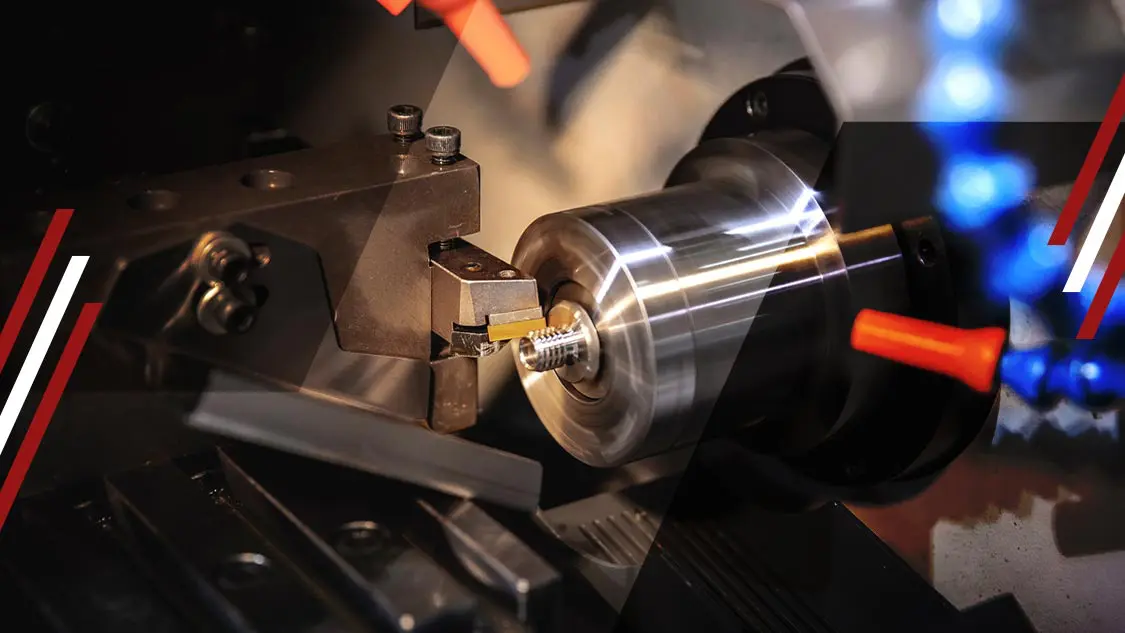

A maquinagem CNC de protótipos para eletrónica de consumo exige um equilíbrio entre velocidade, precisão e qualidade. As tolerâncias dimensionais variam tipicamente entre ±0,005″ e ±0,010″ para a maioria das caraterísticas, com tolerâncias mais apertadas de ±0,002″ a ±0,003″ alcançáveis para superfícies funcionais críticas, quando especificadas. Enquanto as peças de produção podem exigir uma precisão ao nível do mícron em todas as caraterísticas, os protótipos centram-se na precisão das dimensões funcionalmente críticas, permitindo uma rotação mais rápida.

As especificações dos materiais correspondem aos materiais de produção pretendidos, permitindo uma representação exacta do peso, das propriedades térmicas, do desempenho estrutural e do aspeto estético. Os requisitos de acabamento da superfície dependem do objetivo do protótipo - os modelos de aparência podem exigir valores de Ra inferiores a 32 micropolegadas com acabamentos de qualidade superior, como anodização ou polimento, enquanto os protótipos de engenharia podem especificar superfícies maquinadas com cerca de Ra 63-125 micropolegadas, centradas na funcionalidade e não na estética.

Os requisitos de montagem incluem o encaixe adequado entre os componentes correspondentes com folgas apropriadas, o encaixe funcional da rosca para os fixadores e elementos ajustáveis e superfícies de interface representativas para a integração eletrónica. Os protótipos devem demonstrar as sequências de montagem pretendidas, identificar potenciais problemas de interferência e validar os pressupostos ergonómicos através da interação física.

A flexibilidade é fundamental na criação de protótipos - os projectos evoluem frequentemente durante o desenvolvimento, exigindo várias iterações com aperfeiçoamentos progressivos. Os processos de prototipagem eficientes acomodam rapidamente as alterações de design, fornecem feedback sobre a capacidade de fabrico e suportam ciclos de iteração rápidos, medidos em dias e não em semanas. Os requisitos de documentação incluem relatórios de inspeção dimensional, certificações de materiais e documentação fotográfica de apoio às revisões de design e apresentações às partes interessadas.

C. Desafios e soluções para o fabrico

A prototipagem apresenta desafios únicos distintos do fabrico de produção, incluindo alterações frequentes de design que requerem processos flexíveis e um investimento mínimo em configuração, pequenas quantidades (frequentemente 1-10 peças) que tornam as ferramentas dedicadas pouco económicas, prazos apertados que requerem uma resposta rápida, muitas vezes no prazo de 3-7 dias, variedade de materiais que requerem mudanças rápidas entre alumínio, aço, plásticos e ligas especiais, e equilíbrio entre velocidade e qualidade para fornecer uma validação significativa sem custos ao nível da produção.

A Yicen Precision supera os desafios de prototipagem através de abordagens estratégicas optimizadas para flexibilidade e capacidade de resposta. Os nossos centros de maquinação CNC de 5 eixos permitem a produção eficiente de geometrias complexas em configurações únicas, minimizando o tempo de programação e configuração, mantendo a precisão. Os sistemas modulares de fixação acomodam diversas geometrias de peças sem a necessidade de fabrico de fixações personalizadas, reduzindo o tempo de configuração de dias para horas. As extensas bibliotecas de modelos CAM para caraterísticas comuns da eletrónica de consumo, como molduras de smartphones, botões e caixas, aceleram a programação de novos designs.

Células de produção de protótipos dedicadas separam os projectos de rápida execução da produção de grande volume, evitando conflitos de calendário e permitindo uma atenção concentrada nos requisitos específicos do protótipo. Maquinistas com formação cruzada e experiência em aplicações de eletrónica de consumo fornecem um valioso feedback DFM durante a revisão inicial, identificando potenciais problemas antes do início da maquinação e sugerindo melhorias que aumentam a capacidade de fabrico.

O inventário de materiais armazenados especificamente para prototipagem inclui ligas, espessuras e formas habitualmente solicitadas, permitindo o início imediato do projeto sem atrasos na aquisição. As relações estabelecidas com fornecedores de acabamento especializados em anodização, revestimento em pó e galvanização de pequenos lotes garantem protótipos completos com acabamentos representativos da produção, entregues em prazos apertados.

Os processos de qualidade equilibram o rigor com a rapidez - as dimensões críticas são submetidas a verificação por CMM, enquanto as caraterísticas não críticas são objeto de medição por coordenadas ou de inspeção manual. A validação da montagem funcional assegura que as peças se encaixam e funcionam como pretendido. A documentação fotográfica capta a condição de "as-built", apoiando as revisões de projeto. Os relatórios de inspeção identificam quaisquer desvios das especificações com recomendações para o aperfeiçoamento do design.

D. Aplicações e casos de utilização

Prototipagem A maquinagem CNC permite um desenvolvimento rápido em diversas aplicações de eletrónica de consumo:

- Desenvolvimento de smartphones e tablets: Protótipos de estrutura que validam o design industrial, o encaixe do módulo da câmara, o feedback tátil dos botões e as sequências de montagem para a inovação de dispositivos móveis

- Prototipagem de dispositivos vestíveis: Estojos de smartwatches, caixas de rastreadores de fitness e armações de óculos inteligentes que permitem testes ergonómicos, validação do conforto e estudos da experiência do utilizador

- Desenvolvimento de equipamento áudio: Caixas de auscultadores, caixas de altifalantes, chassis de amplificadores e protótipos de botões de controlo para testes acústicos e aperfeiçoamento estético

- Protótipos de produtos para casas inteligentes: Caixas de dispositivos IoT, coberturas de termóstatos, caixas de câmaras de segurança e chassis de hubs para validação funcional e demonstrações para investidores

- Desenvolvimento de periféricos para jogos: Caixas de controladores, estruturas de teclados, protótipos de ratos e conjuntos de joysticks que permitem avaliações ergonómicas e ensaios mecânicos

- Prototipagem em computador portátil e de secretária: Chassis de computadores, plataformas de teclado, molduras de ecrãs e caixas de acessórios para validação térmica e verificação da montagem

- Exploração da nova categoria de produtos: Conceitos inovadores de dispositivos, novos factores de forma e protótipos de tecnologias emergentes que permitem estudos de mercado e demonstrações de prova de conceito

E. Porquê escolher a Yicen Precision para a criação de protótipos?

A Yicen Precision é o parceiro ideal para a criação de protótipos, graças à nossa especialização na entrega rápida de protótipos de alta qualidade para produtos electrónicos de consumo. Os nossos tempos de resposta rápidos entregam a maioria dos protótipos no prazo de 5 a 7 dias úteis a partir da aprovação do projeto, com serviços expeditos de 2 a 3 dias disponíveis para prazos urgentes de apoio a marcos críticos e reuniões com investidores. Compreendemos a pressão dos calendários de desenvolvimento de produtos e damos prioridade à capacidade de resposta.

O nosso apoio de engenharia vai para além da simples maquinação de peças - fornecemos consultoria DFM abrangente, identificando potenciais desafios de fabrico, recomendando melhorias no design, sugerindo abordagens alternativas que reduzem os custos e validando as sequências de montagem. Esta abordagem colaborativa detecta os problemas numa fase inicial, acelera os ciclos de iteração e melhora a capacidade de fabrico do produto final. A nossa equipa tem uma vasta experiência em requisitos de eletrónica de consumo, incluindo tolerâncias apertadas, geometrias complexas e acabamentos de alta qualidade.

As quantidades flexíveis de encomendas acomodam tudo, desde modelos únicos de prova de conceito até séries de produção em ponte de mais de 100 unidades, apoiando o fabrico piloto e os testes de mercado. Não há quantidades mínimas de encomenda que restrinjam a inovação na fase inicial. A experiência em materiais abrange toda a gama de materiais de produção, garantindo que os protótipos representam com exatidão as caraterísticas do produto final, incluindo o peso, o comportamento térmico e o desempenho estrutural.

Capacidades completas de acabamento, incluindo anodização, revestimento em pó, galvanoplastia, polimento e texturas personalizadas, fornecem protótipos com aspeto representativo da produção, permitindo uma avaliação estética significativa e apresentações aos clientes. A documentação de qualidade fornece relatórios de inspeção dimensional, certificações de materiais e fotografias detalhadas que suportam revisões de design e submissões regulamentares.

Com preços transparentes cotados em 24 horas, uma gestão de projectos dedicada que fornece actualizações regulares e um compromisso com o seu sucesso durante todo o desenvolvimento, tornamo-nos o seu parceiro de confiança, acelerando a inovação desde o conceito até aos produtos prontos para o mercado que têm sucesso comercial.