What are Avionic Housings / Enclosures?

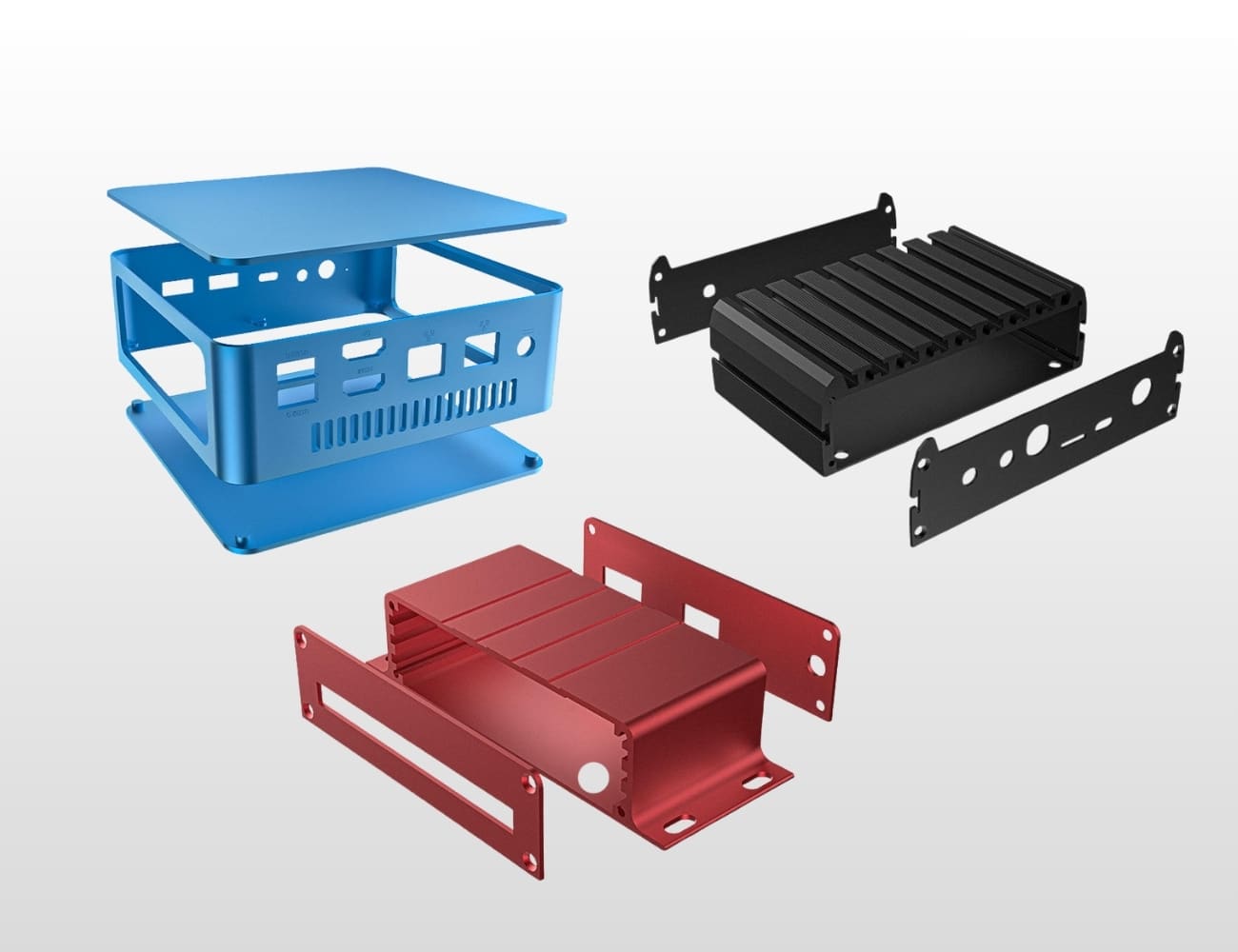

Avionic housings and enclosures are precision-machined protective casings that house critical electronic systems including flight control computers, navigation units, radar systems, communication transceivers, and data acquisition equipment. These specialized enclosures are used throughout commercial aircraft cockpits, military avionics bays, helicopter instrument panels, unmanned aerial vehicle (UAV) control systems, and spacecraft electronics modules. Each avionic enclosure must provide electromagnetic compatibility (EMC), protect sensitive electronics from vibration and shock loads, dissipate heat from high-power components, maintain environmental sealing against moisture and contaminants, and facilitate connector mounting while meeting stringent weight targets. The reliability of aerospace avionic housings directly impacts mission success, flight safety, and system performance across all aircraft platforms.

Principais requisitos técnicos

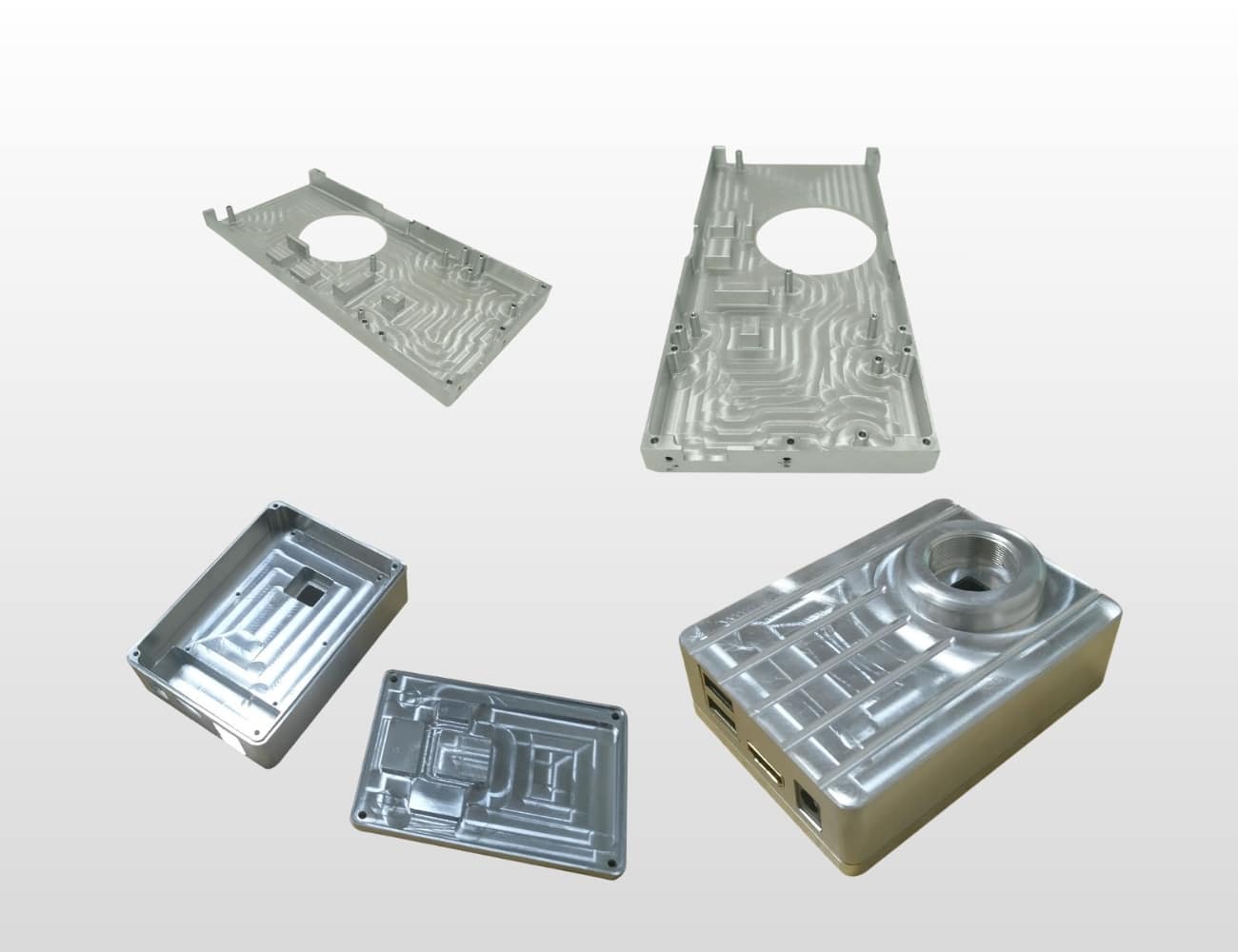

Manufacturing avionic housings and enclosures demands precision engineering and multifunctional design integration. Typical tolerances range from ±0.005″ for general enclosure features to ±0.002″ for mounting boss locations, connector cutouts, and mating surfaces that ensure proper sealing. Material specifications require aerospace-grade aluminum alloys including 6061-T6 (excellent machinability, 45 ksi tensile strength), 7075-T6 (high strength-to-weight ratio), and magnesium alloys (AZ31B, ZE41) for ultra-lightweight applications with complete material certifications.

Surface finish requirements are critical for both functionality and aesthetics. Internal surfaces typically require Ra 125 micropolegadas, while sealing surfaces and gasket interfaces demand Ra 63 microinches or smoother to prevent electromagnetic leakage. Precision avionic enclosures must provide EMI shielding effectiveness of 60-100 dB across frequency ranges from 10 kHz to 18 GHz, achieved through tight-fitting covers, conductive gaskets, and proper grounding. Thermal management is essential—enclosures must dissipate 10-100 watts through convection cooling fins, heat sink integration, or conductive mounting interfaces. Components must withstand vibration testing per MIL-STD-810 (5-2000 Hz), temperature cycling from -55°C to +85°C, and altitude conditions up to 70,000 feet while maintaining structural integrity and sealing performance.

Desafios e soluções para o fabrico

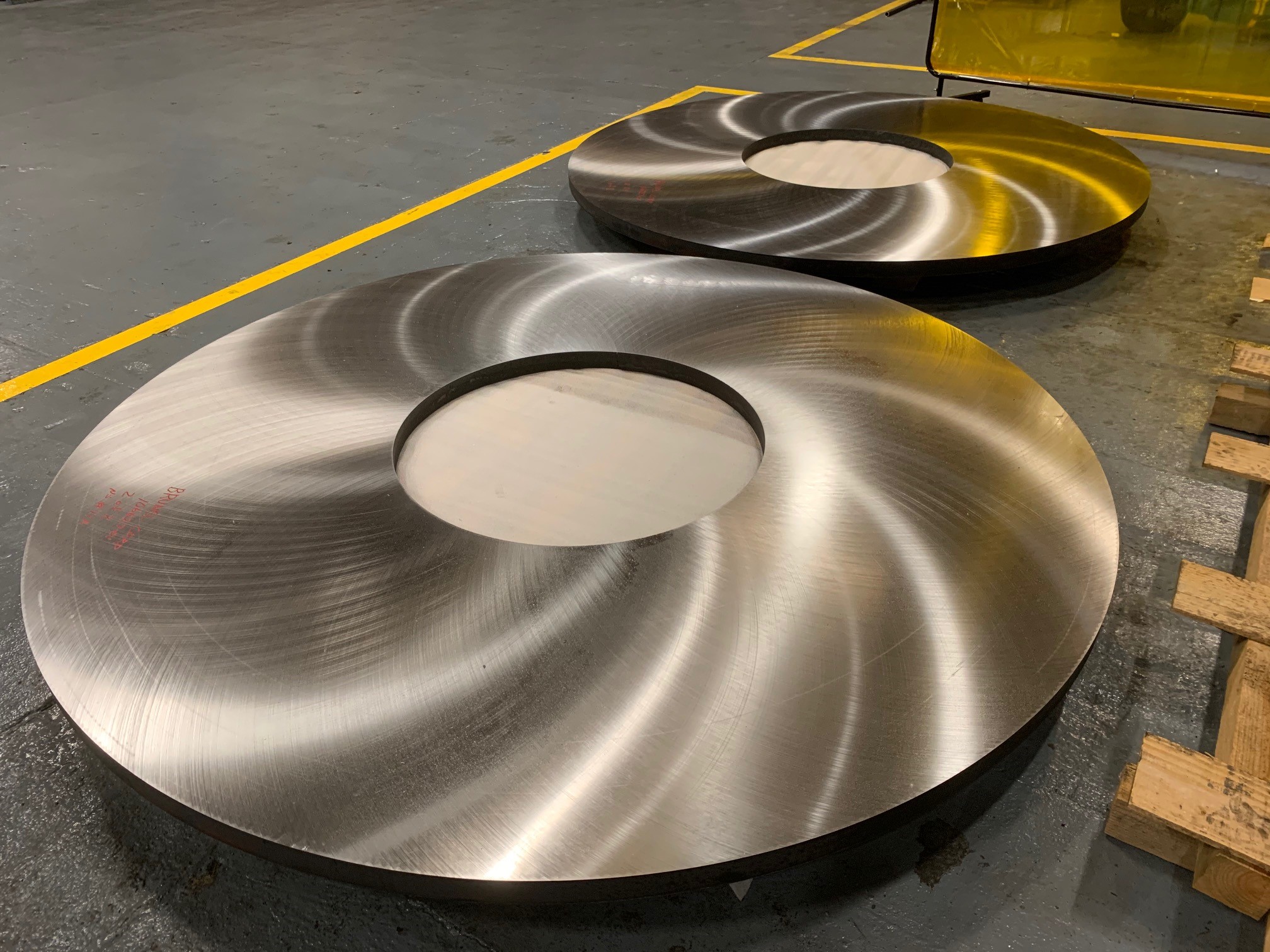

Machining avionic housings and enclosures presents unique technical challenges requiring specialized manufacturing expertise. Complex geometries including internal cavities, cooling fins, lightening pockets, and multiple connector cutouts demand efficient material removal strategies. Thin-wall sections (typically 0.060″-0.100″ thick) are prone to deflection and chatter during machining operations. Large enclosure footprints combined with strict flatness requirements (often ±0.005″ across mounting surfaces) require thermal stability and rigid fixturing.

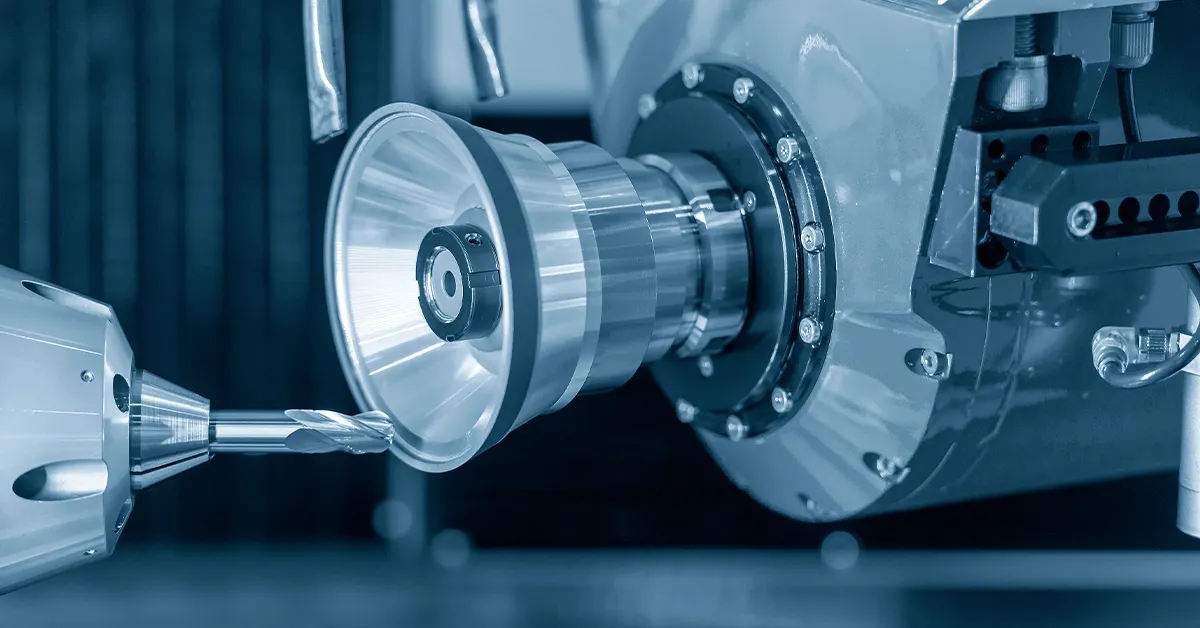

Yicen Precision overcomes these challenges through advanced process engineering and equipment capabilities. Our Centros de maquinagem CNC de 5 eixos enable complete enclosure processing including internal features, external mounting bosses, and angled connector openings in single setups, maintaining geometric accuracy. Adaptive CAM programming optimizes roughing and finishing strategies that balance cycle time with surface quality, particularly critical for EMI shielding effectiveness. High-efficiency milling techniques and climb milling strategies minimize cutting forces on thin-wall sections.

Quality control protocols ensure avionic enclosures meet all functional requirements. First-article CMM inspection verifies all critical dimensions including connector locations, mounting hole patterns, and cover interface flatness. Perfilometria de superfície confirms sealing surface finishes meet gasket compression requirements. We perform dimensional verification of internal cavities ensuring proper PCB clearances and component fit. Every custom avionic housing receives comprehensive dimensional reports, material certifications, and first-article inspection documentation ensuring complete compliance with engineering specifications and aerospace quality standards for electronic packaging applications.

Aplicações e casos de utilização

Precision-machined avionic housings and enclosures protect critical electronics across diverse aerospace platforms:

- Commercial Aircraft Avionics: Flight management system (FMS) housings, autopilot controller enclosures, and communication radio chassis for Boeing and Airbus aircraft

- Military Fighter Avionics: Radar processor housings, mission computer enclosures, and weapons control unit chassis for F-16, F-18, and F-35 tactical aircraft

- Helicopter Avionics Systems: Navigation system enclosures, flight control computer housings, and transponder chassis for military and commercial rotorcraft

- Unmanned Aerial Systems (UAS): Compact avionic enclosures for autopilot systems, payload controllers, and communication modules in tactical and surveillance drones

- Business & Regional Aviation: Integrated avionics housings for glass cockpit displays, GPS navigation units, and weather radar processors

- Spacecraft Electronics: Radiation-hardened enclosures for satellite avionics, orbital maneuvering computers, and telemetry systems

- Ground Support Equipment: Test set enclosures, portable diagnostic equipment housings, and maintenance computer chassis for aircraft servicing operations

Why Choose Yicen Precision for Avionic Housings / Enclosures?

Selecting the right manufacturing partner for avionic housings enclosures CNC machining ensures electronics integration success and certification compliance. Yicen Precision brings specialized capabilities tailored to aerospace electronic packaging requirements. Our serviços de prototipagem rápida accelerate avionics development cycles, delivering first-article enclosures within 7-10 days for fit-check validation, thermal testing, and EMI verification.

Proporcionamos um serviço sem falhas escalabilidade do protótipo à produção, maintaining identical machining processes, surface treatments, and quality protocols that eliminate costly re-qualification and reduce integration risk. Our engineering team delivers proactive Consulta DFM, identifying thermal management opportunities, weight optimization strategies, connector placement optimization, and EMI shielding enhancements during the design phase. Every avionic housing includes rastreabilidade total do material with certified mill test reports, chemical composition verification, and dimensional inspection documentation satisfying AS9100D and avionics OEM requirements.

Our cost-effective approach leverages efficient nesting strategies, optimized toolpaths, and material yield maximization to deliver competitive pricing for both low-volume custom enclosures and production quantities. Yicen Precision understands that avionic housings are critical to mission success and electronic system reliability. Contact us today for engineering consultation and a detailed quote on your avionic housings and enclosures manufacturing requirements.