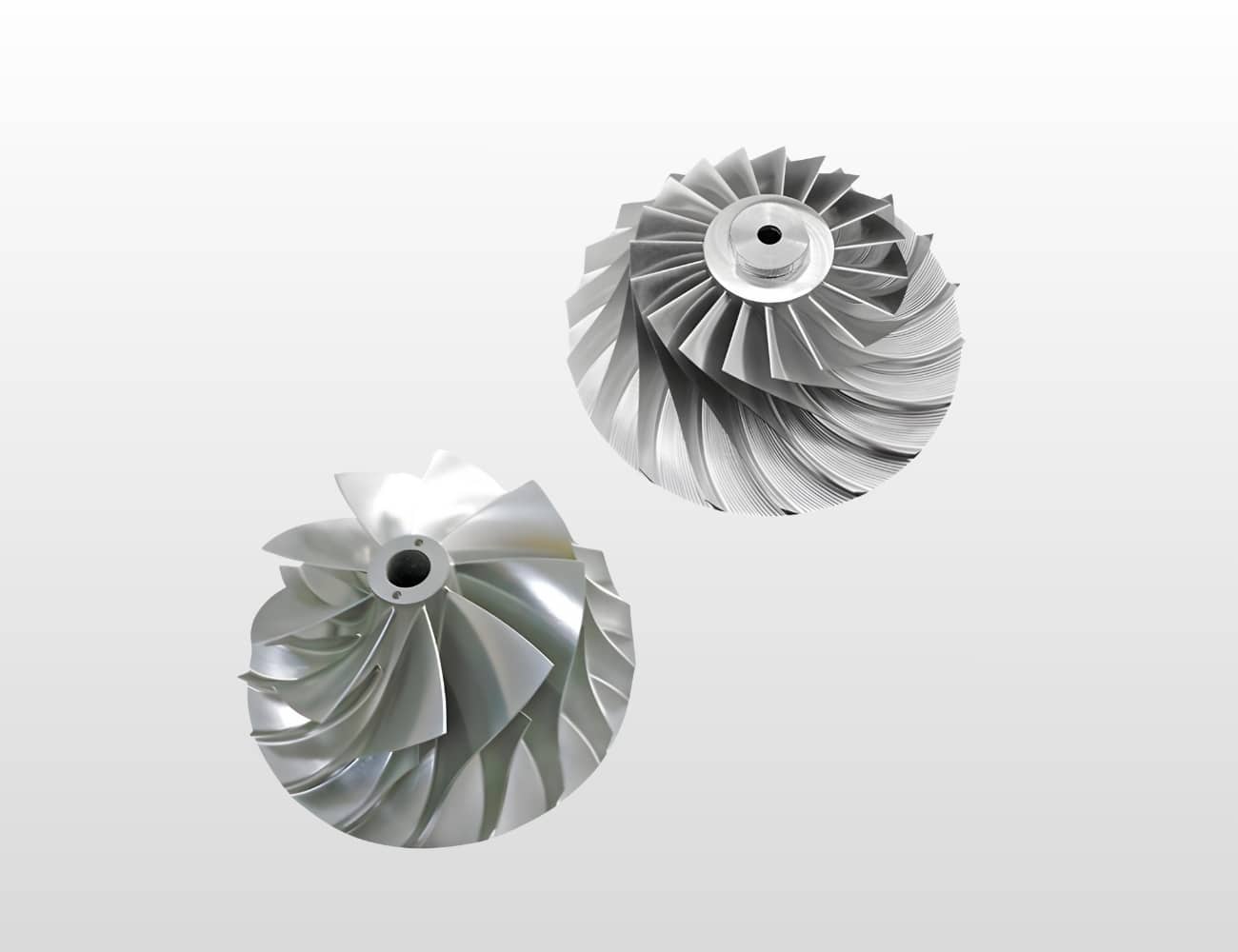

O que são lâminas e discos de turbina?

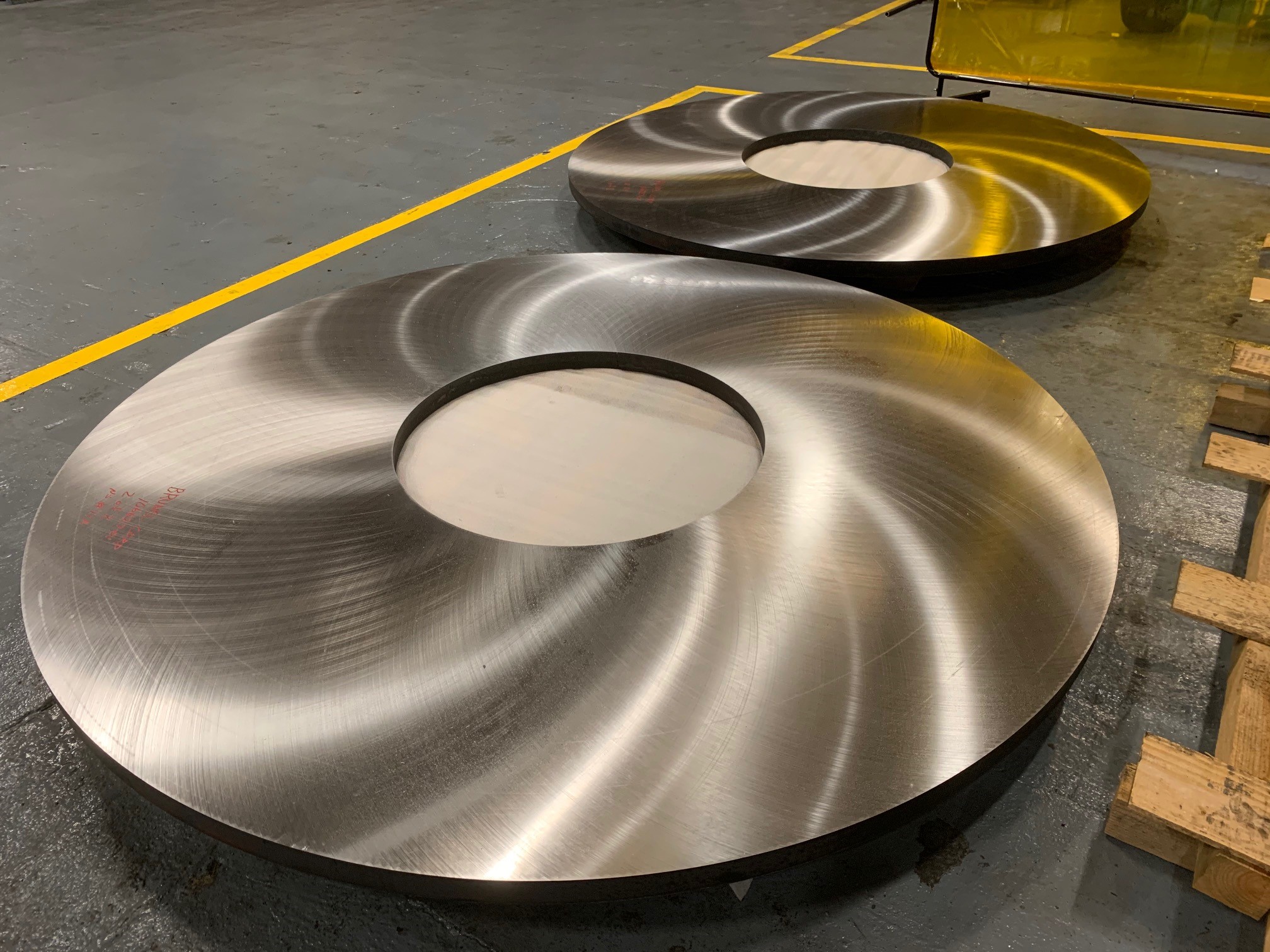

As lâminas e os discos das turbinas são os componentes rotativos das secções quentes dos motores a jato que extraem energia dos gases de combustão a alta temperatura para acionar os compressores e gerar impulso. Os discos de turbina (também chamados rotores ou rodas de turbina) servem de plataformas de montagem, enquanto as pás de turbina se estendem radialmente para captar a energia do fluxo de gás através de perfis de aerofólio com contornos precisos. Estes componentes críticos são utilizados em motores de aviões comerciais, centrais eléctricas de jactos militares, unidades auxiliares de potência (APU), turbinas de gás industriais e motores de turbos-eixo de helicópteros. Cada componente de turbina aeroespacial tem de suportar velocidades de rotação superiores a 10.000 RPM, cargas centrífugas que atingem 40.000 vezes a gravidade e temperaturas do percurso do gás que se aproximam dos pontos de fusão do material, mantendo a estabilidade dimensional ao longo de milhares de ciclos de funcionamento.

Principais requisitos técnicos

O fabrico de lâminas e discos de turbina exige os mais rigorosos padrões de precisão no sector aeroespacial. As tolerâncias típicas variam entre ±0,001″ para caraterísticas de montagem do disco a ±0,0003″ para perfis de aerofólios de pás e bordos de ataque e de fuga. As especificações do material requerem Superligas à base de níquel com certificação AMS incluindo Inconel 718 (tratável termicamente até 1.300°F de serviço), Waspaloy (capacidade de 1.400°F), ligas Rene 80/95 e materiais solidificados direcionalmente ou de cristal único com verificação química completa e documentação da estrutura do grão.

Os requisitos de acabamento da superfície são excecionalmente exigentes. Os aerofólios das pás das turbinas requerem Ra 16 micropolegadas ou mais suave para minimizar a turbulência da camada limite e a transferência de calor. O furo do disco e as ranhuras de fixação da lâmina exigem Ra 8-16 micropolegadas com requisitos específicos de direção de assentamento. Os componentes personalizados das turbinas têm de suportar condições de funcionamento extremas, incluindo gradientes térmicos superiores a 500°F, Os componentes devem ser submetidos a tensões de fadiga cíclicas resultantes de ciclos de arranque/paragem, deformação por fluência a temperaturas elevadas e ataque por oxidação/sulfidação de produtos de combustão. Os componentes requerem uma vida útil à fadiga de baixo ciclo (LCF) superior a 10.000 ciclos e uma resistência à fadiga de alto ciclo (HCF) a falhas induzidas por vibração ao longo dos seus intervalos de serviço.

Desafios e soluções para o fabrico

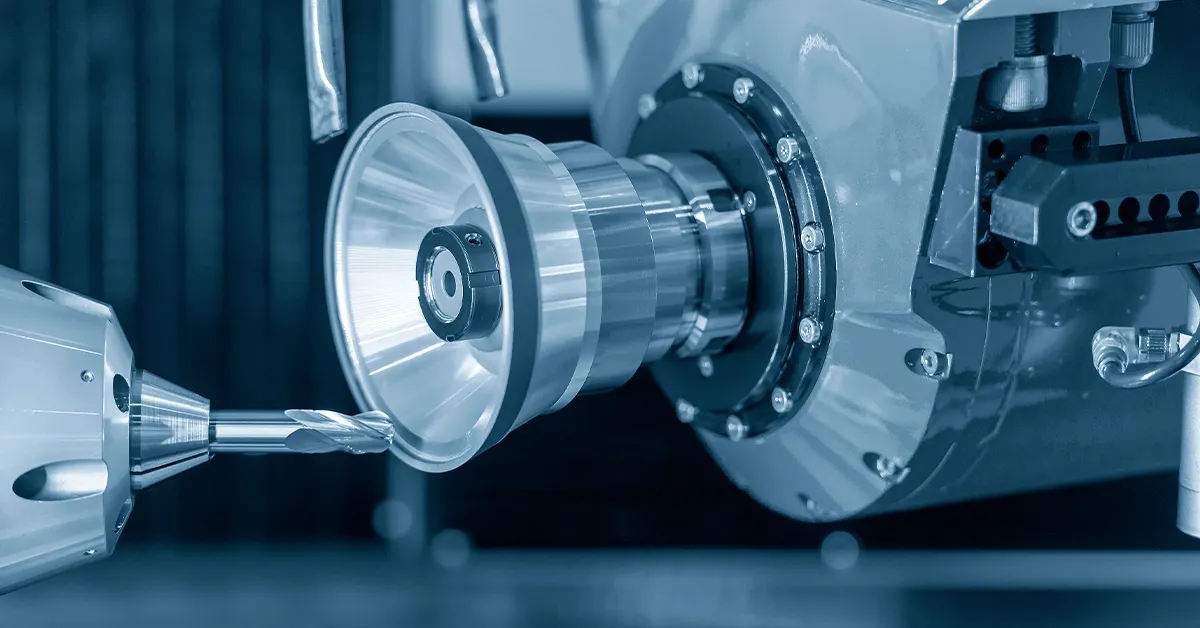

A maquinagem de lâminas e discos de turbinas apresenta os desafios de fabrico mais severos no sector aeroespacial. Geometrias complexas de aerofólios 3D com ângulos de torção, espessura variável (0,020″-0,200″) e curvas compostas exigem interpolação contínua de 5 eixos. As superligas à base de níquel apresentam um endurecimento por trabalho extremo, gerando temperaturas de corte superiores a 1.800°F e provocando um rápido desgaste da ferramenta. As secções finas das lâminas são altamente susceptíveis à vibração e à distorção térmica durante a maquinagem.

A Yicen Precision enfrenta estes desafios através de estratégias especializadas de fabrico de turbinas. Nossos centros de maquinagem CNC de 5 eixos simultâneos com fusos de alta velocidade (20.000+ RPM) permitem uma maquinação eficiente de aerofólios utilizando fresas de ponta esférica e de barril. Software CAM avançado com módulos de turbomáquinas gera percursos de ferramenta optimizados que mantêm uma carga de aparas e uma velocidade de superfície constantes em perfis de lâminas complexos. Utilizamos ferramentas de corte em cerâmica e CBN especificamente concebido para superligas de níquel, combinado com fornecimento de líquido de refrigeração de alta pressão (1.000+ PSI) para gestão do calor.

Os protocolos de controlo de qualidade são exaustivos para os componentes da turbina. Inspeção do primeiro artigo inclui medições CMM completas das coordenadas do aerofólio da pá, comparadas com perfis teóricos dentro de ±0.0005″. Varrimento ótico e perfilometria verificar os raios dos bordos de ataque e de fuga e o acabamento da superfície. Cada pá de turbina é submetida a inspeção por penetração fluorescente (FPI) para detetar microfissuras. Os discos de turbina recebem inspeção por ultra-sons para defeitos internos e ensaios de correntes de Foucault de ranhuras para fixação de lâminas. A documentação completa inclui certificações de materiais, registos de tratamento térmico, relatórios dimensionais e certificados NDT garantindo a rastreabilidade total dos componentes rotativos críticos.

Aplicações e casos de utilização

As lâminas e os discos de turbina maquinados com precisão desempenham funções vitais em todas as plataformas de propulsão aeroespacial:

- Motores para a aviação comercial: Componentes de turbina de alta pressão (HPT) e de turbina de baixa pressão (LPT) para as famílias de motores CFM56, GE90, PW4000 e Rolls-Royce Trent

- Caças militares: Conjuntos de turbinas de pós-combustão e pás de turbina de cristal único para motores de F-22, F-35 e aviões tácticos avançados

- Motores de turbina para helicópteros: Rotores e pás de turbinas de potência livre para T700, T64 e centrais eléctricas de helicópteros comerciais

- Unidades de potência auxiliares (APUs): Conjuntos compactos de rodas e pás de turbina para produção eléctrica e pneumática a bordo de aeronaves

- Aviação de negócios: Componentes de turbinas para as séries de motores Honeywell TFE731, Pratt & Whitney Canada PT6 e Williams FJ44

- Sistemas de propulsão de UAV: Lâminas e discos de microturbinas para aeronaves não tripuladas de longa duração que necessitem de centrais eléctricas compactas e eficientes

- Revisão e reparação de motores: Lâminas de turbina de substituição e componentes de disco renovados para instalações MRO que servem frotas comerciais e militares

Por que escolher a Yicen Precision para lâminas e discos de turbina?

A seleção de um fabricante qualificado para a maquinagem CNC de discos de lâminas de turbina requer experiência comprovada nas aplicações aeroespaciais mais exigentes. A Yicen Precision oferece capacidades especializadas para componentes críticos de motores rotativos. A nossa serviços de prototipagem avançada apoiar novos programas de desenvolvimento de motores, fornecendo componentes de turbina de primeiro artigo no prazo de 14-21 dias para ensaios aerodinâmicos e validação estrutural.

Proporcionamos um serviço sem falhas transição do protótipo para a produção, A nossa equipa de engenharia metalúrgica, preservando parâmetros de processo validados, desenhos de fixação e protocolos de inspeção que aceleram os prazos de certificação e reduzem o risco do programa. A nossa equipa de engenharia metalúrgica e de fabrico oferece Consulta DFM, O projeto de uma turbina é um processo de desenvolvimento que inclui a análise das concentrações de tensão, a conceção da passagem de arrefecimento e a viabilidade de fabrico durante a fase de projeto. Cada pá e disco de turbina inclui rastreabilidade total do material com certificações de fusão, análise da estrutura do grão, dados de testes de propriedades mecânicas e documentação de tratamento térmico que satisfazem os requisitos da AS9100D e do OEM do motor.

Nosso compromisso com a excelência dos componentes de turbina utiliza estratégias de ferramentas especializadas, experiência em usinagem de superligas e sistemas de qualidade rigorosos para fornecer componentes que funcionam de forma confiável nos ambientes operacionais mais adversos. A Yicen Precision entende que as lâminas e os discos de turbina são o coração do desempenho e da segurança do motor. Contacte-nos hoje para obter uma consulta de engenharia e um orçamento detalhado sobre os seus requisitos de fabrico de lâminas e discos de turbina.