Fornecemos prototipagem rápida e pequenas séries de CNC, permitindo que os inovadores no sector da energia testem novos designs e passem rapidamente do conceito à implementação.

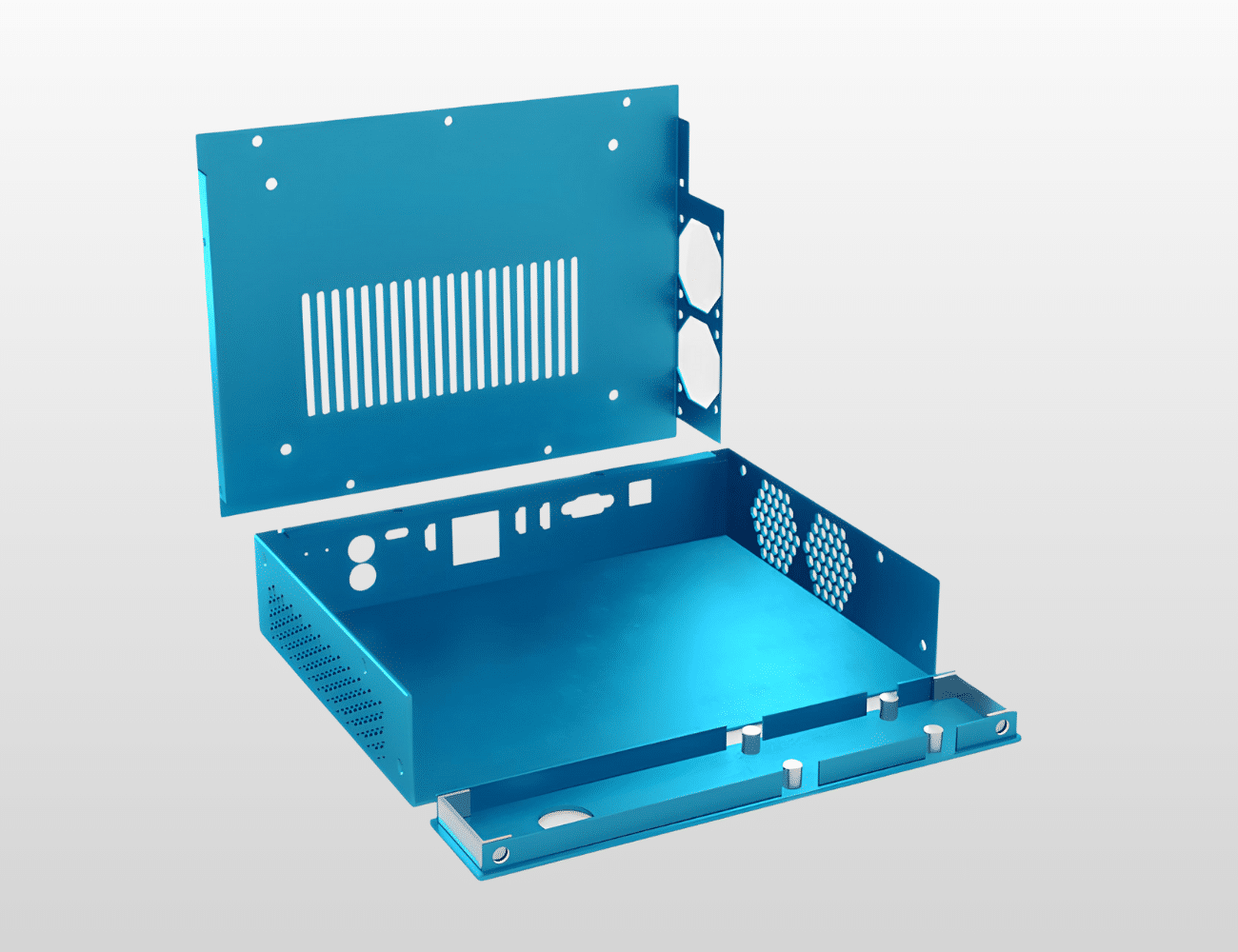

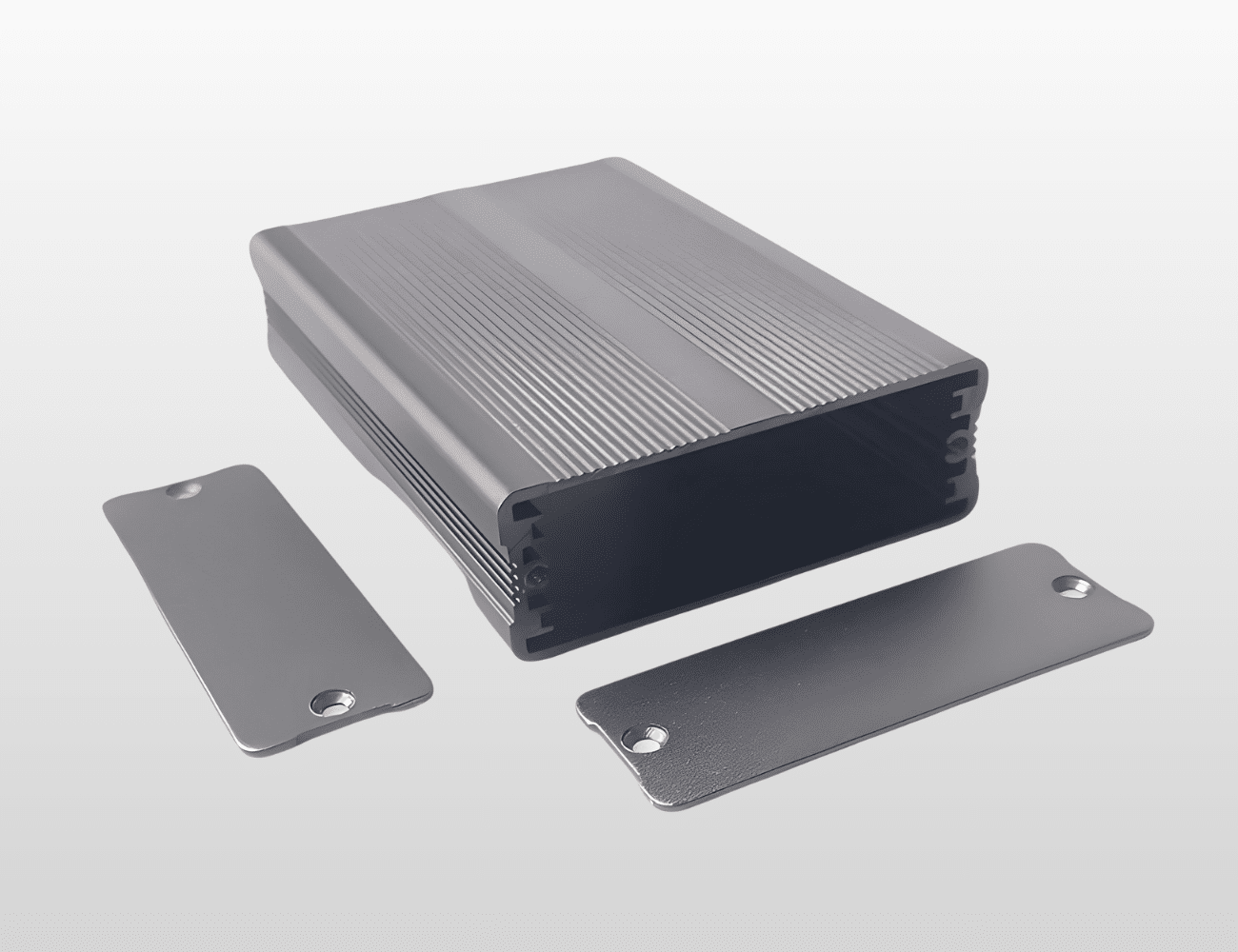

Precision-engineered power inverter housings designed for optimal electromagnetic shielding, heat dissipation, and environmental protection in renewable energy applications. Our advanced CNC machining delivers robust enclosures with integrated cooling features and precision component mounting that ensure reliable power conversion and extended operational life. Request your custom inverter housing solution today.

A transição para a energia limpa e renovável requer componentes que possam suportar condições extremas e oferecer um desempenho consistente. Precisão Yicen desempenha um papel crucial nesta missão, fornecendo peças maquinadas em CNC concebidas para sistemas eólicos, solares e de armazenamento de energia. Desde cubos de turbinas a invólucros de baterias, a nossa experiência em maquinagem garante resistência, durabilidade e uma integração perfeita, ajudando os inovadores do sector da energia a avançar com confiança.

Power inverter housings provide the critical protective enclosure for power electronics that convert DC energy from solar panels, wind turbines, and battery systems into grid-compatible AC power, delivering electromagnetic interference (EMI) shielding, thermal management, environmental sealing, and structural support for high-value semiconductor components. These housings must balance effective heat dissipation with electromagnetic containment while maintaining IP-rated environmental protection across wide temperature ranges and demanding installation environments.

Yicen Precision specializes in power inverter housings CNC machining utilizing our advanced 3-axis, 4-axis, and 5-axis milling centers capable of producing complex enclosure geometries with integrated heat sink features, precision mounting bosses, and EMI gasket grooves. We machine inverter housings from aluminum alloys 6061-T6 and 6063-T5 for thermal performance, stainless steel 304 and 316 for corrosion resistance, and specialized alloys for EMI shielding requirements, maintaining tolerances within ±0.005″ on critical mounting surfaces and ±0.003″ on gasket seating areas. Our ISO 9001 and AS9100-compliant manufacturing processes incorporate EMI shielding effectiveness testing, thermal interface verification, and environmental sealing validation to ensure every inverter housing meets stringent standards including UL 1741, IEEE 1547, and IEC 62109 for reliable protection of power conversion equipment in solar photovoltaic systems, wind energy installations, and battery energy storage applications.

Concebemos componentes CNC de elevado desempenho adaptados a sistemas de energia renovável, desde a energia eólica e solar a tecnologias avançadas de baterias, construídos para durabilidade e sustentabilidade.

Fabrico CNC de alta precisão com tecnologia avançada e eficiência inigualável.

Produção CNC optimizada utilizando máquinas de última geração para uma qualidade consistente.

Fabrico e montagem especializados de componentes CNC complexos sob o mesmo teto.

Operações CNC totalmente automatizadas que permitem uma maquinação rápida, precisa e fiável.

Optimizado para fornecer peças CNC de qualidade superior com velocidade e precisão.

Fabrico CNC de ponta a ponta com fluxos de trabalho contínuos e resultados superiores.

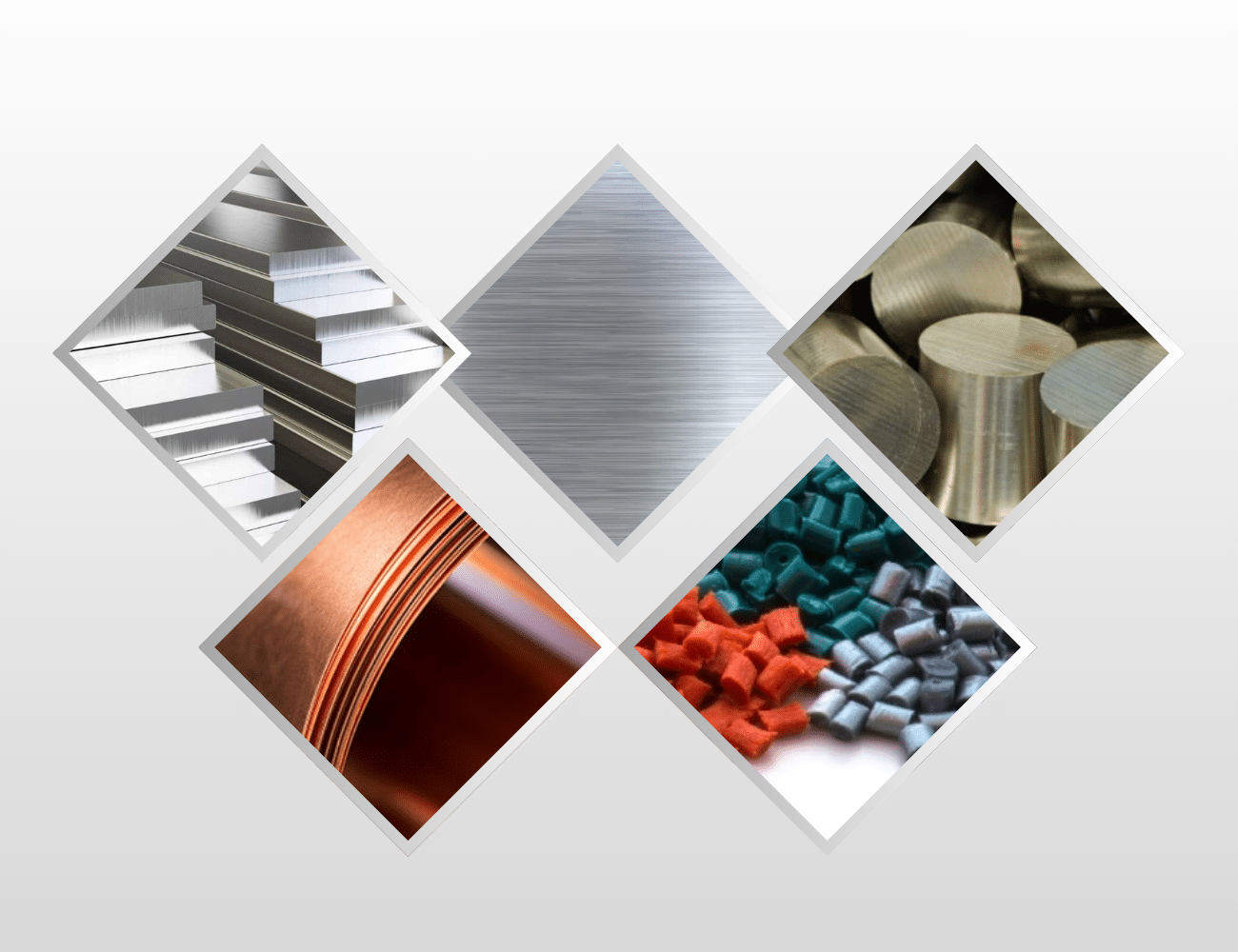

A Yicen Precision oferece uma vasta seleção de metais duráveis e compósitos avançados para satisfazer as exigências de resistência estrutural, térmica e química dos sistemas eólicos, solares e de armazenamento de energia.

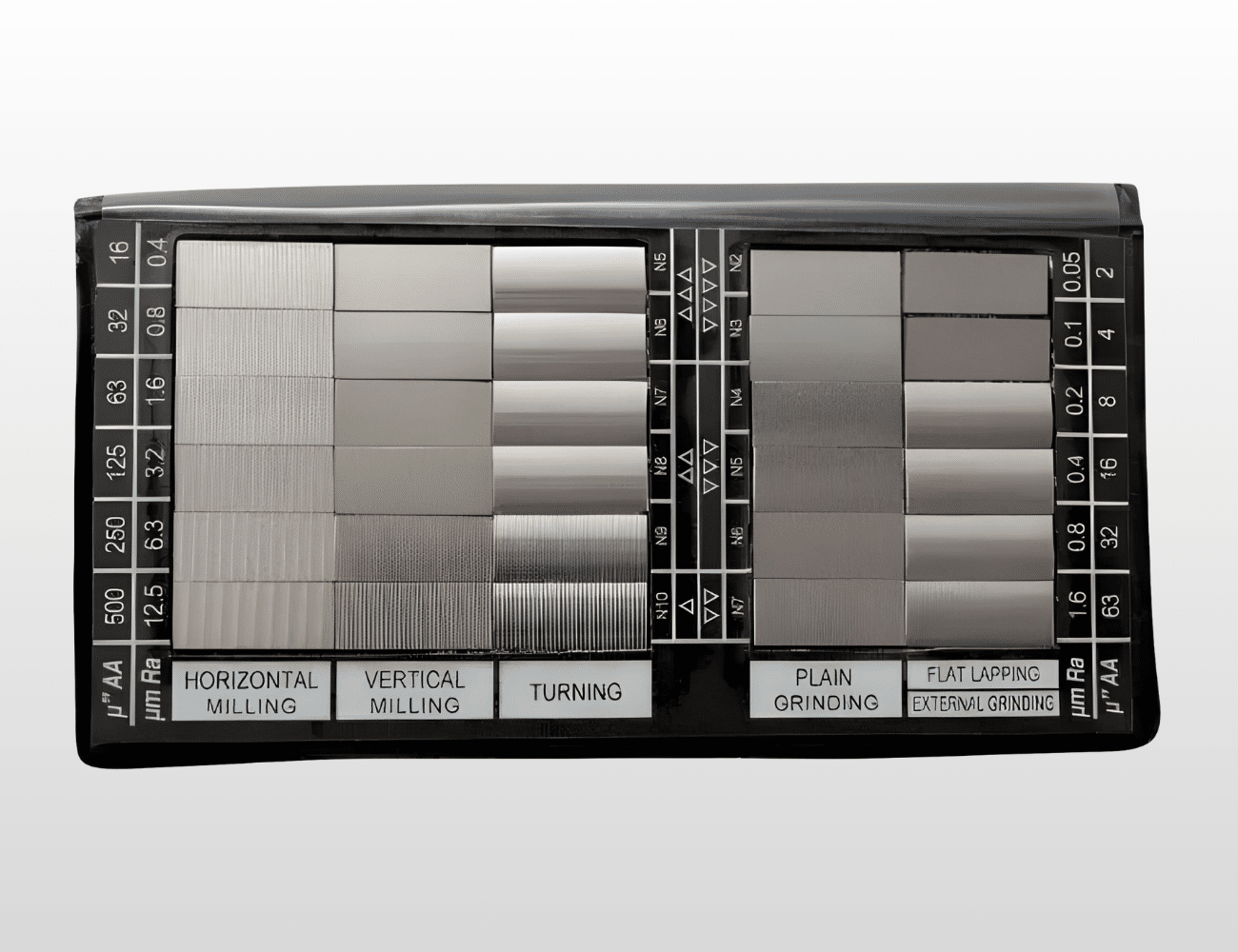

Para os sistemas de energia renovável, os acabamentos de superfície devem garantir a resistência à corrosão, a proteção contra o desgaste e a fiabilidade a longo prazo em ambientes agressivos. A Yicen Precision aplica revestimentos protectores e funcionais que prolongam a vida útil dos componentes utilizados em aplicações eólicas, solares e de baterias.

A Yicen Precision serve um vasto espetro de indústrias, abrangendo a indústria aeroespacial, automóvel, eletrónica, médica e muito mais. Somos especializados no fornecimento de peças fiáveis e de alta qualidade, concebidas para responder aos desafios de engenharia únicos de cada indústria.

Veja porque é que os clientes confiam na Yicen Precision para a maquinagem CNC. Os nossos testemunhos destacam a satisfação com a precisão, a qualidade, a entrega atempada e o apoio dedicado, fomentando parcerias duradouras em todos os sectores a nível mundial.

A Yicen Precision forneceu-nos serviços de maquinagem CNC de primeira linha. A sua atenção ao pormenor e eficiência são inigualáveis.

Tempos de execução rápidos e maquinação precisa. A Yicen Precision fornece sempre trabalho de qualidade, a tempo e horas.

Serviço excecional e maquinação fiável. A Yicen Precision é o nosso fornecedor de referência para todos os projectos relacionados com CNC.

Óptima comunicação e excelente trabalho artesanal. A Yicen Precision cumpre sistematicamente as nossas exigentes especificações.

Somos especialistas em converter as suas ideias em componentes funcionais de alta qualidade, com uma velocidade e precisão sem paralelo. Com tecnologia avançada e perícia artesanal, criamos peças que cumprem as especificações mais complexas.

Power inverter housings provide the critical protective enclosure for power electronics that convert DC energy from solar panels, wind turbines, and battery systems into grid-compatible AC power, delivering electromagnetic interference (EMI) shielding, thermal management, environmental sealing, and structural support for high-value semiconductor components. These housings must balance effective heat dissipation with electromagnetic containment while maintaining IP-rated environmental protection across wide temperature ranges and demanding installation environments.

Yicen Precision specializes in power inverter housings CNC machining utilizing our advanced 3-axis, 4-axis, and 5-axis milling centers capable of producing complex enclosure geometries with integrated heat sink features, precision mounting bosses, and EMI gasket grooves. We machine inverter housings from aluminum alloys 6061-T6 and 6063-T5 for thermal performance, stainless steel 304 and 316 for corrosion resistance, and specialized alloys for EMI shielding requirements, maintaining tolerances within ±0.005″ on critical mounting surfaces and ±0.003″ on gasket seating areas. Our ISO 9001 and AS9100-compliant manufacturing processes incorporate EMI shielding effectiveness testing, thermal interface verification, and environmental sealing validation to ensure every inverter housing meets stringent standards including UL 1741, IEEE 1547, and IEC 62109 for reliable protection of power conversion equipment in solar photovoltaic systems, wind energy installations, and battery energy storage applications.

Power inverter housings are engineered enclosures that contain and protect power electronics including IGBT modules, gate drivers, DC link capacitors, control circuitry, and thermal management systems that convert DC power to AC power in renewable energy installations. These housings function as multifunctional assemblies providing structural mounting for heavy components, electromagnetic shielding to prevent interference with communication systems and grid equipment, heat dissipation through finned surfaces or liquid cooling interfaces, and environmental protection against moisture, dust, and temperature extremes. They are essential in residential and commercial solar inverters ranging from 3 kW to 100 kW, central inverters for utility-scale solar farms up to 8 MW, wind turbine power converters, battery energy storage system inverters, and microgrid power conditioning equipment. The housing’s design directly influences inverter efficiency through thermal management effectiveness, system reliability through EMI containment, and installation flexibility through environmental protection ratings.

Power inverter housings CNC machining requires maintaining flatness tolerances of ±0.005″ on heat sink mounting surfaces to ensure proper thermal interface material compression and heat transfer, with EMI gasket groove dimensions held to ±0.003″ for effective shielding continuity. Material specifications typically demand aluminum alloys with minimum thermal conductivity of 160 W/m·K for effective heat dissipation, or stainless steel with minimum tensile strength of 70 ksi for structural applications requiring enhanced corrosion resistance. Surface finish requirements range from 63 Ra on internal mounting surfaces to 32 Ra or better on thermal interface areas and gasket seating surfaces. Housings must achieve IP65 or IP66 environmental protection ratings through precision-machined sealing surfaces, withstand operating temperature ranges from -40°C to 70°C ambient (with internal temperatures reaching 85°C), and provide EMI shielding effectiveness exceeding 40 dB from 150 kHz to 1 GHz per CISPR 22 Class B requirements. Mounting hole positional tolerances of ±0.010″ ensure proper alignment with circuit boards and power modules, while wall thickness uniformity within ±0.015″ provides consistent thermal performance across the enclosure.

Producing power inverter housings presents significant challenges including machining large thin-wall enclosures without distortion, creating integrated heat sink fin arrays with tight spacing while maintaining dimensional control, and achieving the precise flatness required for thermal interface contact across large mounting surfaces. The combination of deep pocket milling for component cavities and thin-wall sections for weight optimization demands careful process planning to prevent vibration-induced chatter. Inverter housing manufacturing also faces difficulties in producing EMI shielding features including continuous gasket grooves around access panels, grounding provisions for shielding effectiveness, and filtered penetrations for cable entries while maintaining environmental sealing integrity.

Yicen Precision overcomes these challenges through strategic workholding designs that support thin-wall sections with vacuum fixtures or low-profile clamps, preventing deflection during high-speed machining operations while maintaining accessibility for tool approach. Our advanced CAM programming incorporates adaptive toolpaths that adjust feed rates based on material engagement, minimizing cutting forces by 30-40% compared to conventional strategies and enabling successful machining of thin-wall features down to 0.060″ thickness. Climate-controlled manufacturing environments maintain temperature stability within ±2°F, preventing thermal expansion errors during precision operations on large enclosures. For integrated heat sink production, we utilize specialized high-feed milling cutters and multi-tooth finishing tools that achieve fin spacing as tight as 0.100″ with height uniformity within ±0.010″. Quality control protocols include flatness verification using precision surface plates and dial indicators, EMI gasket groove dimensional inspection via optical comparators, environmental sealing validation through water spray testing per IP rating requirements, and CMM verification of all mounting hole positions and critical dimensions. We employ stress-relief processes between roughing and finishing operations to eliminate machining-induced stresses that cause warping, and validate thermal interface flatness using thermal impedance testing on production samples.

Power inverter housings CNC machining serves diverse applications across renewable energy power conversion systems:

Our specialized expertise in precision inverter housing manufacturing combines advanced machining capabilities with comprehensive understanding of power electronics thermal management, EMI shielding requirements, and environmental protection standards. We maintain production capacity for housing sizes ranging from compact 10-liter residential units to large 500+ liter central inverter enclosures, with machining envelopes accommodating components up to 72 inches in length. Fast turnaround times of 3-5 weeks for production quantities support aggressive product development cycles and rapid market entry, while our rapid prototyping services deliver functional housings within 7-10 business days for thermal validation, EMI testing, and design iteration. Our engineering team provides comprehensive DFM consultation, optimizing enclosure designs for enhanced thermal performance through strategic heat sink fin geometry, internal air flow optimization, and thermal interface surface preparation that improves heat transfer by 20-30% compared to standard machined surfaces. We collaborate on lightweighting initiatives that reduce housing mass by 15-25% through topology optimization and strategic ribbing while maintaining structural rigidity and thermal performance. We provide integrated solutions including EMI gasket selection, thermal interface material recommendations, and environmental sealing design support. Complete material traceability documentation accompanies every shipment, including mill certifications, dimensional inspection reports, flatness measurements on thermal mounting surfaces, and environmental protection test results. We deliver cost-effective solutions through efficient nesting strategies that maximize aluminum plate utilization, automated production processes that reduce per-unit costs for volume production, and quality systems ensuring zero-defect environmental sealing and thermal interface preparation—providing reliable protection for your valuable power electronics that enables maximum inverter efficiency, minimizes electromagnetic interference, and delivers decades of reliable operation in demanding renewable energy installations from desert solar farms to offshore wind platforms.

Explorar Serviços de maquinagem para obter informações especializadas sobre maquinagem CNC, tendências da indústria, sugestões de fabrico e actualizações tecnológicas - concebidas para o manter informado, inspirado e na vanguarda da engenharia de precisão.

Como é que a Yicen Precision contribui para a rápida inovação no domínio das novas energias?

Fornecemos prototipagem rápida e pequenas séries de CNC, permitindo que os inovadores no sector da energia testem novos designs e passem rapidamente do conceito à implementação.

Os componentes CNC são adaptáveis aos sistemas de energia híbrida?

A maquinagem CNC permite a personalização de peças para configurações híbridas, como a energia solar mais armazenamento, garantindo a compatibilidade entre diversas tecnologias energéticas.

Como é que a maquinagem CNC reduz os custos de manutenção em sistemas renováveis?

Ao produzir componentes duráveis e resistentes à corrosão, a maquinagem CNC minimiza o desgaste, reduzindo a frequência e o custo das reparações em sistemas eólicos e solares.

A maquinagem CNC pode apoiar as tecnologias do hidrogénio e das pilhas de combustível?

Sim, o CNC é ideal para produzir placas de fluxo de precisão, colectores e conectores em células de combustível de hidrogénio, onde a precisão afecta diretamente a produção de energia e a segurança.