A. What are Bearings and Linear Motion Parts?

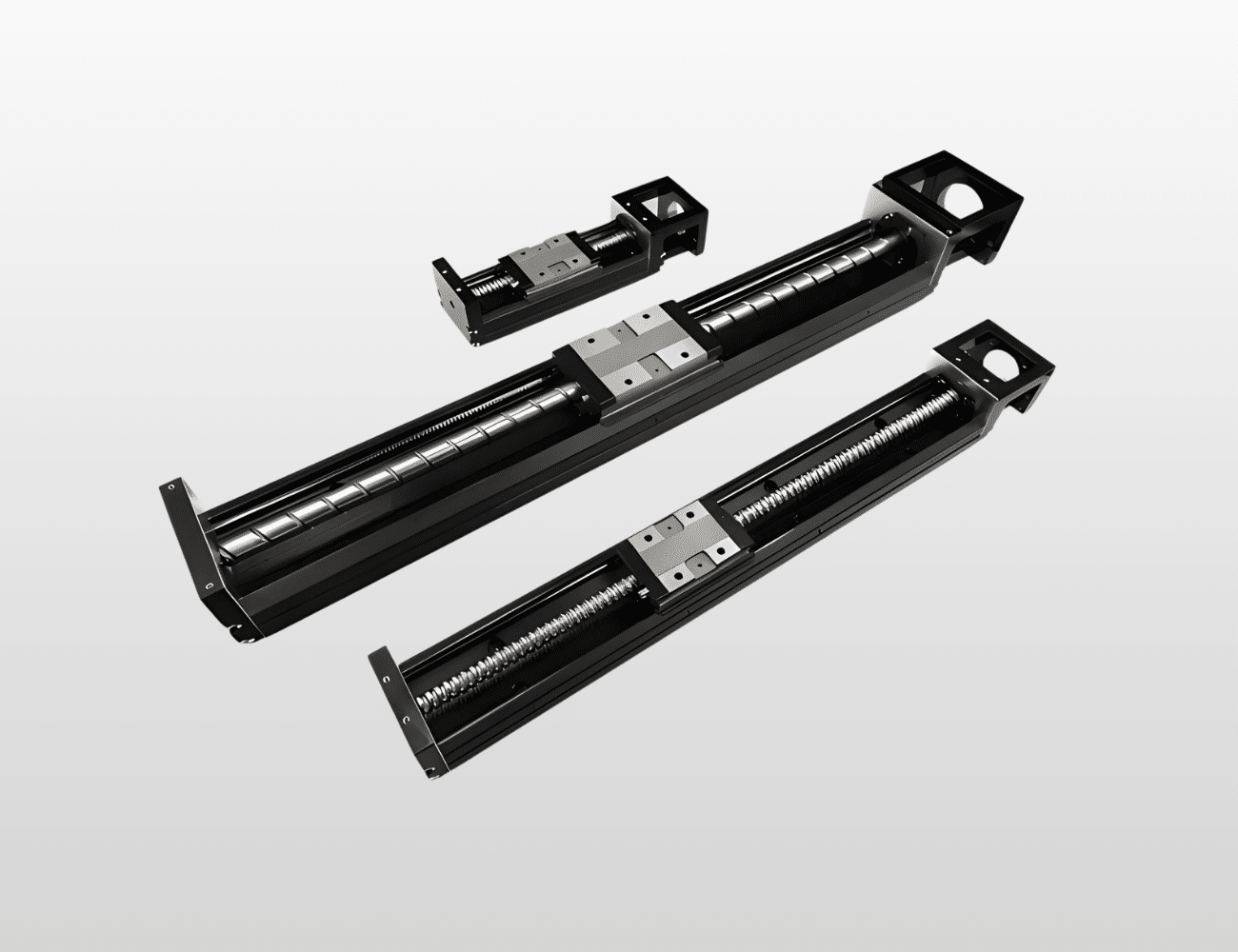

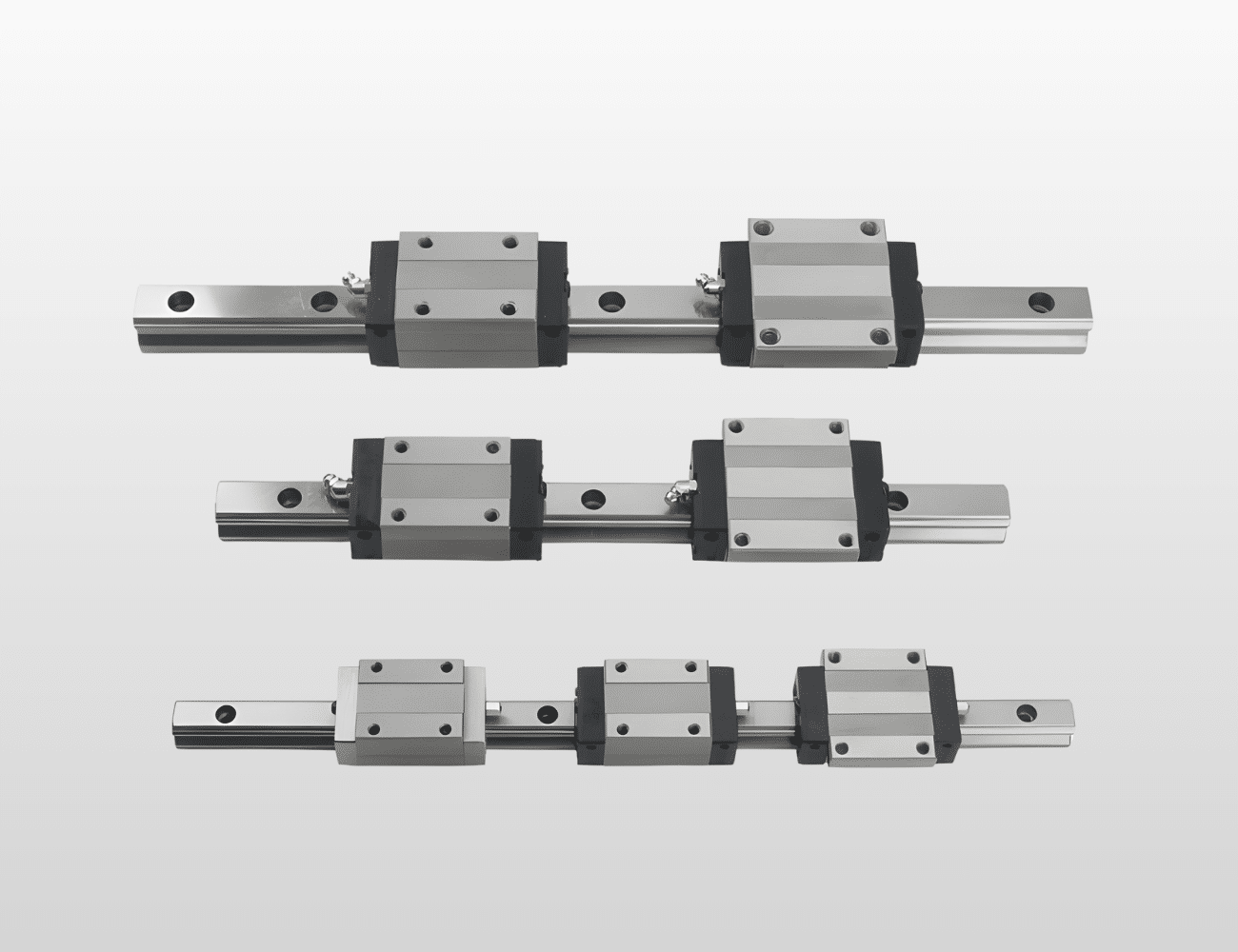

Bearings and linear motion parts are precision-machined components that facilitate controlled movement between moving and stationary elements in robotic systems. These include bearing housings and mounts, linear guide rails and carriages, precision bushings and sleeve bearings, ball screw support blocks, linear slide assemblies, and cam followers. Bearing components provide rotary motion support with minimal friction, while linear motion parts enable precise translation along defined axes. These elements are essential in industrial robotic arms, Cartesian coordinate robots, precision assembly systems, medical surgical robots, pick-and-place automation, CNC-integrated robotics, and semiconductor handling equipment. The precision and surface quality of these machined components directly impact positioning accuracy, motion smoothness, load capacity, system rigidity, and operational lifespan across manufacturing, medical, electronics, and aerospace robotics applications.

B. Principais requisitos técnicos

Bearings and linear motion parts for robotics demand exceptional precision with tolerances of ±0.0001″ to ±0.0005″ on critical dimensions including bore diameters, raceway surfaces, and mounting interfaces to ensure proper fit and alignment. Concentricity specifications typically require TIR below 0.0002″ between bearing bores and mounting surfaces. Surface finish requirements are stringent, with Ra 4 to Ra 8 microinches on bearing contact surfaces and linear guide raceways to minimize friction and wear. Roundness and cylindricity tolerances must be maintained within 0.0002″ for proper bearing function. Parallelism between linear guide mounting surfaces requires tolerances of ±0.0003″ per 12 inches to ensure smooth carriage travel. Material hardness specifications typically demand HRC 58-62 for bearing races and guide surfaces after heat treatment. Load ratings must account for both radial and axial forces, with proper material selection and geometry to prevent premature failure. Components must maintain dimensional stability across temperature ranges from -40°F to 200°F and operate reliably in environments with contamination, vibration, and shock loads. Lubrication groove geometries require precise depths and profiles for proper oil distribution.

C. Desafios e soluções para o fabrico

Machining bearings and linear motion parts presents significant challenges including maintaining extremely tight tolerances on cylindrical features, achieving exceptional surface finishes on bearing contact surfaces, and preserving dimensional accuracy through heat treatment processes. Thin-walled bearing housings are susceptible to distortion from cutting forces and work-holding clamping. Linear guide rail straightness must be maintained within microns across extended lengths. Material hardness in pre-hardened steels increases tool wear and requires careful speed and feed optimization. Achieving proper surface finish on internal bearing bores demands specialized boring and grinding techniques.

Yicen Precision addresses these manufacturing challenges through integrated 5-axis CNC machining combined with precision grinding operations that achieve the tight tolerances and surface finishes required for bearing and linear motion applications. Our CAM software optimizes cutting strategies for both rough and finish operations, controlling heat generation and minimizing deflection. We employ specialized work-holding fixtures designed specifically for bearing components, supporting thin walls without inducing stress or distortion. Precision boring cycles with interpolation techniques achieve exceptional bore accuracy and surface finish. CMM inspection verifies all critical dimensions including concentricity, roundness, surface finish, and parallelism with documented traceability. Our quality control measures include coordinate heat treatment processes with certified partners, followed by finish grinding operations to restore critical dimensions while maintaining hardness specifications. Statistical process control monitors dimensional trends across production runs, ensuring every bearing and linear motion part meets exact specifications for optimal performance and extended operational life.

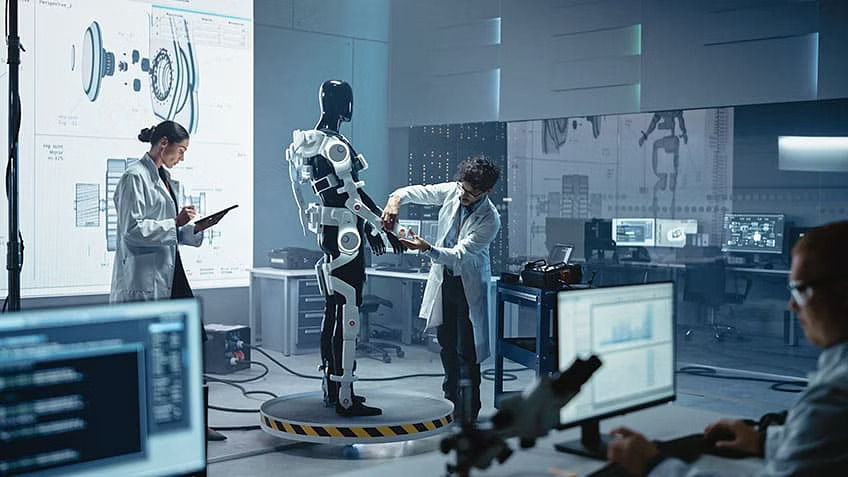

D. Aplicações e casos de utilização

Bearings and linear motion parts are utilized across diverse robotic applications:

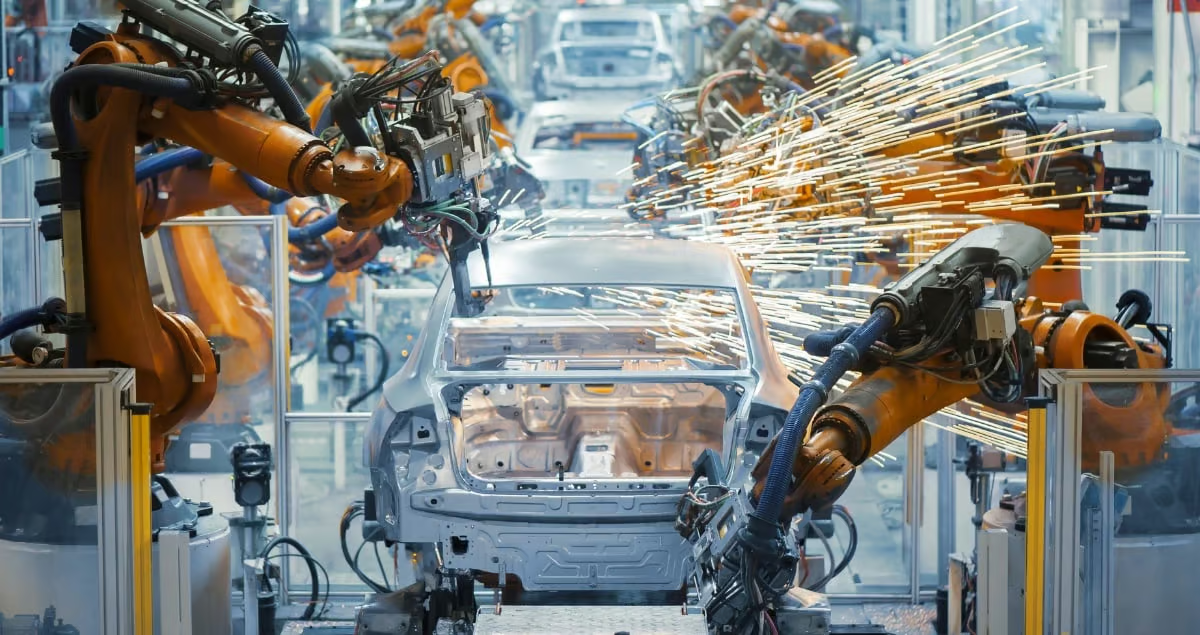

- Industrial Robotic Arms: Precision bearings for joint assemblies and rotary actuators requiring millions of cycles

- Gantry & Cartesian Robots: Linear guide rails and carriages for X-Y-Z positioning systems in material handling and assembly

- Collaborative Robots (Cobots): Low-friction bearing systems for smooth, controlled motion in human-robot interaction

- Medical Surgical Robots: Sterile-compatible bearing housings and linear slides for minimally invasive procedures

- Pick-and-Place Systems: High-speed linear motion components for electronics assembly and packaging automation

- CNC Machine Tool Integration: Ball screw support bearings and linear guides for robotic loading and tool changing

- Semiconductor Handling: Ultra-clean bearing assemblies and precision linear stages for wafer processing equipment

- Inspection & Measurement Robots: Precision linear motion parts for coordinate measuring machines and automated quality control

E. Why Choose Yicen Precision for Bearings and Linear Motion Parts?

Yicen Precision delivers specialized expertise in manufacturing complex bearings and linear motion parts with rapid turnaround times suitable for both prototype development and high-volume production. Our engineering team provides comprehensive Design for Manufacturability (DFM) consultation, optimizing bearing designs, material selection, lubrication strategies, and mounting configurations for maximum performance and longevity. We maintain complete material traceability with certified mill test reports and heat treatment documentation for every component batch. Our scalable production capabilities accommodate orders ranging from single custom bearing housings to thousands of production linear guide rails with consistent quality throughout. State-of-the-art inspection equipment including CMMs, roundness testers, surface finish analyzers, and bore gauges ensure dimensional accuracy and surface quality conformance. We coordinate certified heat treatment services including through hardening, case hardening, and nitriding processes, followed by precision grinding to achieve final specifications. Cost-effective solutions are achieved through optimized machining strategies, efficient material utilization, and integrated grinding operations that reduce lead times without compromising quality. Contact us for a custom quote and engineering consultation to discover how our precision bearings and linear motion parts can enhance your robotic system’s accuracy, smoothness, and reliability.