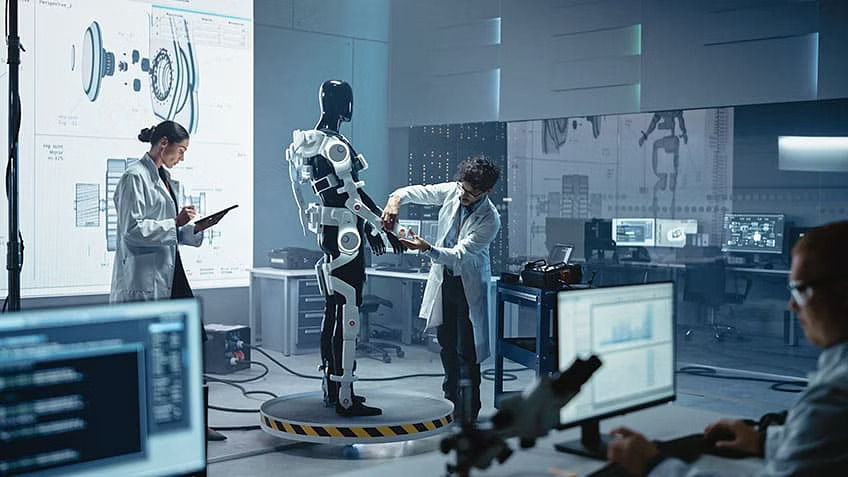

Precision-engineered control system components designed for optimal electronic protection, signal integrity, and reliable operation in robotic platforms. Our robotics industry-grade CNC machining delivers controller housings, circuit board mounts, and interface components with exceptional dimensional accuracy and integrated features. Experience AS9100-certified manufacturing excellence for your critical control system needs.

Desde engrenagens e actuadores de alta precisão a ferramentas e caixas personalizadas, criamos componentes orientados para o desempenho que melhoram a eficiência e a fiabilidade do sistema robótico. As nossas capacidades avançadas de maquinação garantem tolerâncias apertadas e qualidade superior, suportando tudo, desde robôs industriais a máquinas autónomas. Com experiência numa vasta gama de materiais, fornecemos soluções robustas que cumprem os exigentes padrões da engenharia robótica.

Control system components are critical elements that house, protect, and integrate electronic controllers, processors, circuit boards, and interface modules within robotic systems. These essential parts include controller housings, PCB mounting frames, connector panels, heat sink assemblies, and cable management structures that ensure proper electrical function and signal integrity. Yicen Precision specializes in manufacturing control system components that meet the demanding requirements of industrial automation, collaborative robots, autonomous vehicles, medical robotics, and aerospace applications.

Our advanced CNC machining capabilities utilize 5-axis milling, multi-axis lathes, and precision tooling to produce complex component geometries with integrated mounting features, thermal management elements, EMI shielding provisions, and precise alignment surfaces. We work with high-performance materials including aluminum 6061 and 7075 for thermal conductivity and lightweight designs, stainless steel 304 and 316 for corrosion resistance, titanium alloys for aerospace applications, and specialized alloys for enhanced electromagnetic compatibility. Every control system component undergoes comprehensive quality verification through AS9100 and NADCAP-compliant processes, ensuring tight tolerances, proper electrical isolation, thermal dissipation capability, and dimensional stability that guarantee reliable electronic protection and long-term performance in demanding robotics applications.

Oferecemos componentes maquinados com precisão, concebidos para melhorar o desempenho, a fiabilidade e a funcionalidade dos sistemas robóticos em várias aplicações.

Fabrico CNC de alta precisão com tecnologia avançada e eficiência inigualável.

Produção CNC optimizada utilizando máquinas de última geração para uma qualidade consistente.

Fabrico e montagem especializados de componentes CNC complexos sob o mesmo teto.

Operações CNC totalmente automatizadas que permitem uma maquinação rápida, precisa e fiável.

Optimizado para fornecer peças CNC de qualidade superior com velocidade e precisão.

Fabrico CNC de ponta a ponta com fluxos de trabalho contínuos e resultados superiores.

Oferecemos uma variedade de ligas metálicas e plásticos de alto desempenho para peças de robótica, assegurando durabilidade e fiabilidade.

O nosso acabamentos de superfície, incluindo anodização e galvanoplastia, melhorar resistência à corrosão e desempenho em aplicações robóticas.

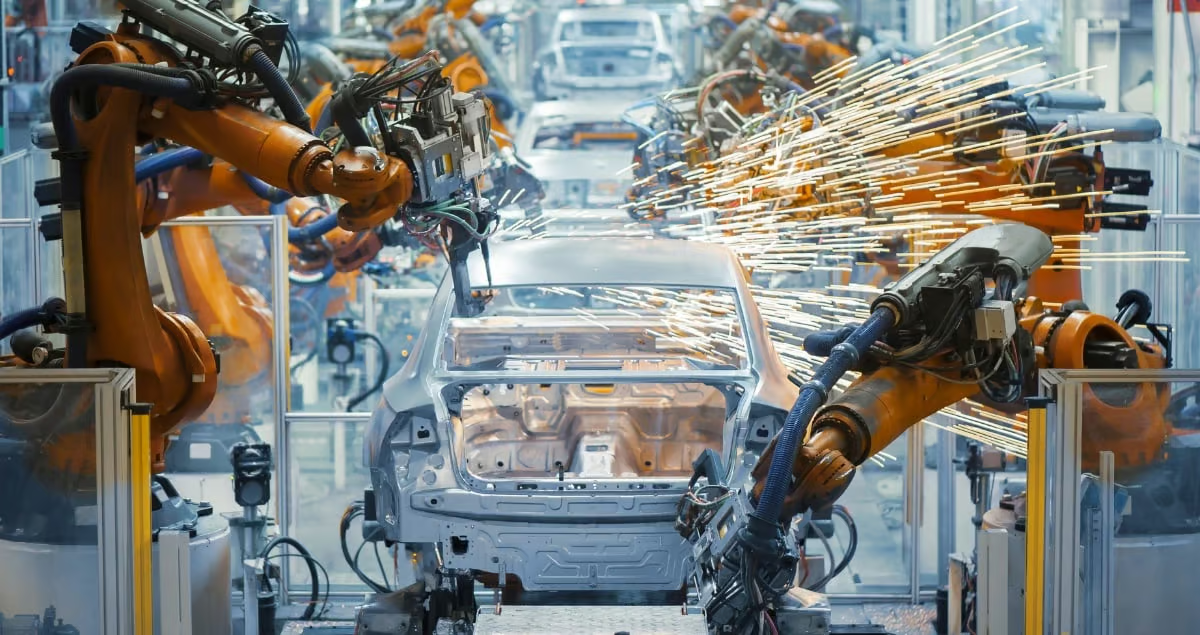

A Yicen Precision serve um vasto espetro de indústrias, abrangendo a indústria aeroespacial, automóvel, eletrónica, médica e muito mais. Somos especializados no fornecimento de peças fiáveis e de alta qualidade, concebidas para responder aos desafios de engenharia únicos de cada indústria.

Veja porque é que os clientes confiam na Yicen Precision para a maquinagem CNC. Os nossos testemunhos destacam a satisfação com a precisão, a qualidade, a entrega atempada e o apoio dedicado, fomentando parcerias duradouras em todos os sectores a nível mundial.

A Yicen Precision forneceu-nos serviços de maquinagem CNC de primeira linha. A sua atenção ao pormenor e eficiência são inigualáveis.

Tempos de execução rápidos e maquinação precisa. A Yicen Precision fornece sempre trabalho de qualidade, a tempo e horas.

Serviço excecional e maquinação fiável. A Yicen Precision é o nosso fornecedor de referência para todos os projectos relacionados com CNC.

Óptima comunicação e excelente trabalho artesanal. A Yicen Precision cumpre sistematicamente as nossas exigentes especificações.

Somos especialistas em converter as suas ideias em componentes funcionais de alta qualidade, com uma velocidade e precisão sem paralelo. Com tecnologia avançada e perícia artesanal, criamos peças que cumprem as especificações mais complexas.

Control system components are precision-machined mechanical elements designed to house, mount, and protect electronic control hardware including microcontrollers, PLCs, motion controllers, servo drives, circuit boards, and communication modules in robotic systems. These components include controller enclosures with integrated cooling, precision PCB mounting frames with standoffs, connector interface panels with precise cutouts, backplane assemblies, heat sink mounting plates, cable routing brackets, and shielded compartments for sensitive electronics. They provide structural support, thermal management, electromagnetic shielding, vibration dampening, and environmental protection for control electronics. Control system components are essential in industrial robotic controllers, autonomous vehicle ECUs, collaborative robot control units, medical device controllers, warehouse automation systems, and aerospace flight computers. The precision and protective qualities of these machined components directly impact controller reliability, signal integrity, thermal performance, electromagnetic compatibility, and system longevity across manufacturing, logistics, medical, and defense robotics applications.

Control system components for robotics demand exceptional precision with tolerances of ±0.001″ to ±0.003″ on mounting surfaces, alignment pins, and circuit board support structures to ensure proper component fitment and electrical contact. Flatness specifications on PCB mounting surfaces typically require 0.001″ across the mounting area to prevent board flexing and solder joint stress. Hole positioning for mounting standoffs and connectors requires positional tolerances of ±0.003″ to align with PCB hole patterns and mating interfaces. Perpendicularity between mounting surfaces and alignment features must maintain ±0.002″ to ensure proper connector engagement and heat sink contact. Material specifications must provide adequate thermal conductivity for heat dissipation, typically requiring aluminum alloys with minimum thermal conductivity of 120 W/m·K. Surface finish requirements range from Ra 32 to Ra 63 microinches on mounting surfaces with special attention to thread quality for electrical grounding. EMI shielding effectiveness requires proper material selection and surface preparation, achieving attenuation of 40-80 dB across operational frequency ranges. Components must provide adequate electrical isolation between circuits, typically maintaining 500V minimum isolation. Thread specifications must conform to UNC, UNF, or metric standards with Class 2B or 3B fits for secure hardware installation. Control system components must withstand operating temperatures from -40°F to 185°F, shock loads up to 50G, and vibration across 10-2000 Hz frequency ranges.

Machining control system components presents unique challenges including maintaining tight tolerances across multiple mounting holes with precise positional relationships, achieving flatness specifications on circuit board mounting surfaces, and creating complex cutout geometries for connectors and displays with minimal edge breakout. Thin-walled sections in controller housings are susceptible to deflection during machining. Integrated cooling features require precise fin spacing and depth control. Thread quality for grounding studs must provide reliable electrical continuity. Multiple component variations with similar base geometries require efficient manufacturing strategies to minimize setup time while maintaining quality.

Yicen Precision overcomes these manufacturing challenges through advanced 5-axis CNC machining that enables complete component fabrication in single setups, ensuring perfect alignment of mounting holes, connector cutouts, and thermal management features. Our CAM software optimizes tool paths for precision drilling and milling operations, utilizing reference hole strategies that maintain positional accuracy across entire mounting patterns. We employ specialized fixtures designed for control system components, supporting thin-walled structures without inducing stress while maintaining accessibility to all features. High-speed machining techniques with optimized cutting parameters minimize burrs on connector cutouts and ensure clean edges. CMM inspection verifies all critical dimensions including hole positions, flatness specifications, perpendicularity, and thread quality with documented traceability. Our quality control measures include electrical continuity testing for grounding paths, thermal interface verification for heat sink contact, and functional fit checks with actual PCBs and connectors, ensuring every control system component meets exact specifications for optimal electronic protection and performance.

Control system components are utilized across diverse robotic platforms:

Yicen Precision delivers specialized expertise in manufacturing complex control system components with rapid turnaround times suitable for both prototype development and high-volume production runs. Our engineering team provides comprehensive Design for Manufacturability (DFM) consultation, optimizing component designs for thermal management, EMI shielding, PCB mounting strategies, connector integration, and manufacturing efficiency. We maintain complete material traceability with certified mill test reports and material certifications for every component. Our scalable production capabilities accommodate both custom single-unit controller housings for specialized applications and high-volume production orders with consistent quality standards throughout. State-of-the-art inspection equipment including CMMs, optical comparators, and thread gauges ensure dimensional accuracy and mounting surface quality. We provide additional services including anodizing for electrical insulation, chemical film coating for corrosion resistance, and custom surface treatments for specific environmental requirements. Assembly capabilities allow us to install threaded inserts, heat-set standoffs, and mounting hardware as complete assemblies ready for PCB integration. Cost-effective solutions are achieved through optimized machining strategies, efficient material utilization, and modular design approaches that accommodate multiple component variations with minimal setup changes. Contact us for a custom quote and engineering consultation to discover how our precision control system components can enhance your robotic platform’s reliability, thermal performance, and electronic protection.

Explorar Serviços de maquinagem para obter informações especializadas sobre maquinagem CNC, tendências da indústria, sugestões de fabrico e actualizações tecnológicas - concebidas para o manter informado, inspirado e na vanguarda da engenharia de precisão.