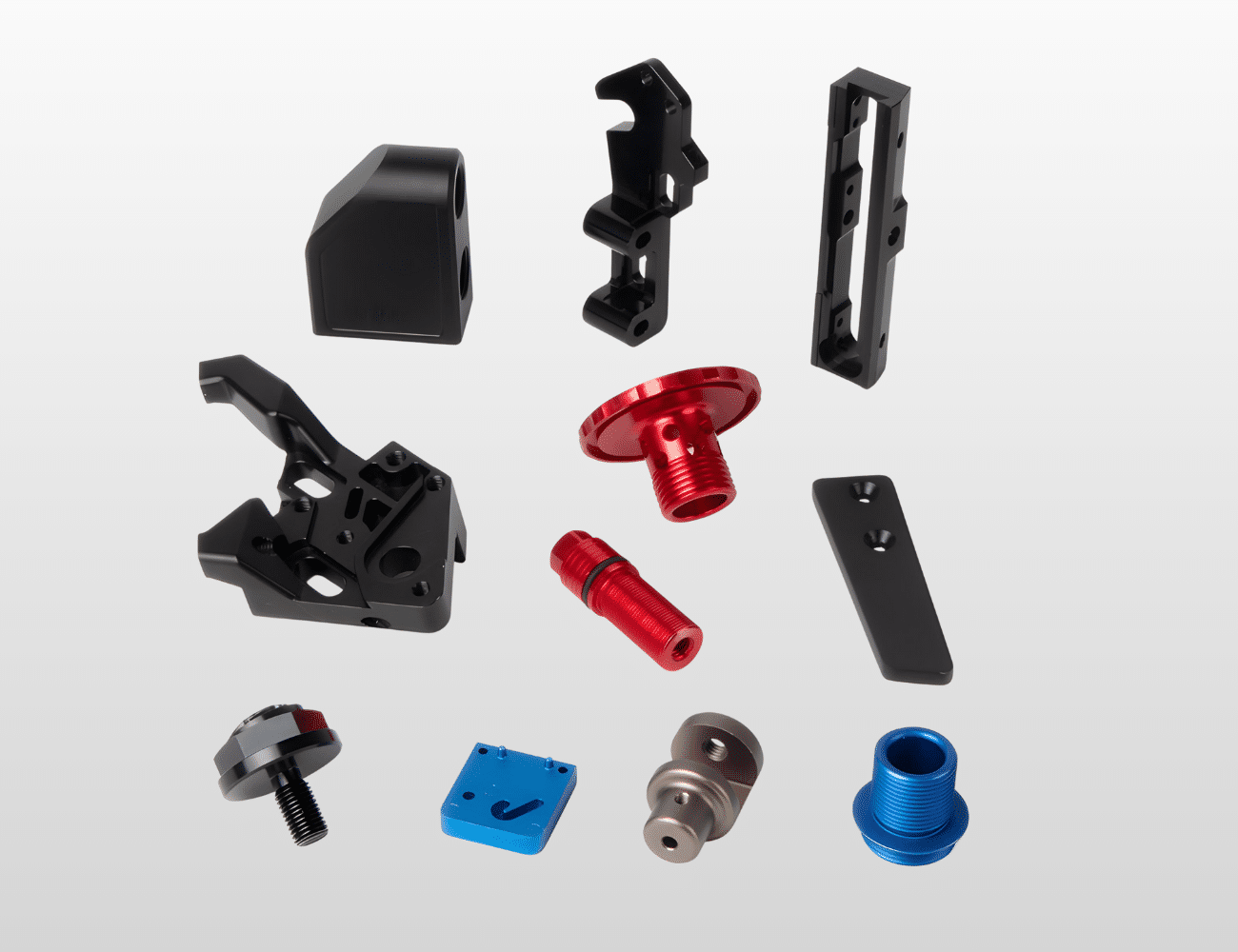

A. What are Drive Train Components?

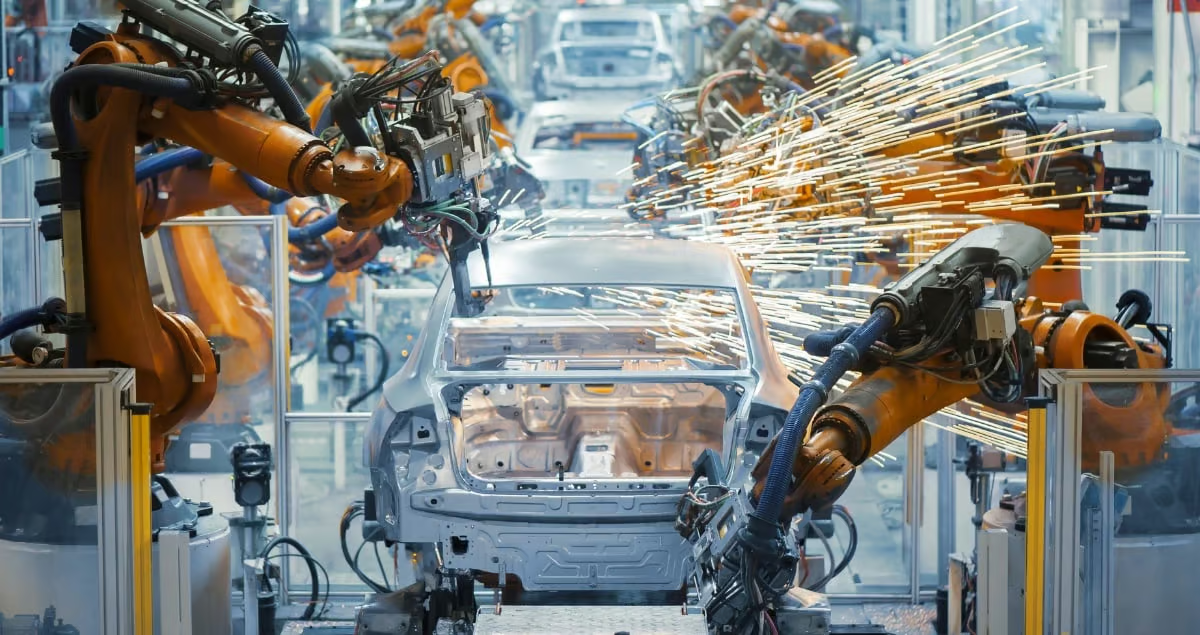

Drive train components are mechanical elements that transmit rotational power and motion from motors and actuators to the functional mechanisms of robotic systems. These include precision gears (spur, helical, bevel, and planetary), drive shafts with keyways and splines, flexible and rigid couplings, timing pulleys, and gear housings. They are used extensively in industrial robots, mobile robotics platforms, AGVs, warehouse automation systems, and collaborative robotic arms. Drive train components enable speed reduction, torque multiplication, directional changes, and precise motion control essential for robotic operations. The accuracy and durability of these machined components directly impact robot performance, positioning accuracy, payload capacity, and overall system reliability across manufacturing, logistics, medical, and defense robotics applications.

B. Principais requisitos técnicos

Drive train components for robotics demand exceptional precision with tolerances ranging from ±0.0003″ to ±0.0008″ on critical dimensions to ensure proper meshing and minimal backlash. Gear tooth profiles require precise AGMA quality standards, typically Grade 8-10 for industrial robotics applications. Material specifications must provide adequate hardness (typically HRC 55-62 for gear teeth) while maintaining core toughness to resist shock loads. Surface finish requirements are stringent, with Ra 16 to Ra 8 microinches on bearing surfaces and gear tooth flanks to minimize friction and wear. Components must withstand high contact stresses, often exceeding 200,000 PSI on gear tooth faces. Concentricity and runout specifications typically require TIR (Total Indicated Runout) below 0.0005″ on shaft journals and coupling interfaces. Heat treatment and proper case hardening are essential for wear resistance while maintaining dimensional stability. Balancing requirements prevent vibration in high-speed applications.

C. Desafios e soluções para o fabrico

Machining drive train components presents significant challenges including maintaining precise gear tooth geometry across multiple teeth, achieving tight concentricity between multiple diameters, and preserving dimensional accuracy during heat treatment processes. Thin-walled gear blanks are susceptible to distortion from cutting forces and thermal expansion. Complex internal features like splines, keyways, and oil passages require specialized tooling access. Material hardness in pre-hardened steels increases tool wear and demands careful process control.

Yicen Precision addresses these manufacturing challenges through integrated 5-axis CNC machining that maintains datum relationships throughout production, minimizing setup errors. Our advanced CAM software optimizes cutting strategies for gear tooth generation, using specialized milling and hobbing techniques to achieve precise involute profiles. We employ precision fixtures and work-holding systems designed specifically for drive train components, preventing deflection during machining operations. CMM inspection verifies gear geometry, tooth spacing, and profile accuracy with documented measurement protocols. Our heat treatment partners provide certified processes with minimal distortion, followed by finish grinding operations to restore critical dimensions. Statistical process control monitors key characteristics across production runs, ensuring every drive train component meets exact specifications for seamless integration and optimal power transmission efficiency.

D. Aplicações e casos de utilização

Drive train components are essential across numerous robotic applications:

- Industrial Robotic Arms: Multi-axis robots requiring precision gear reducers and harmonic drives for accurate positioning

- Automated Guided Vehicles (AGVs): Drive wheels, motor couplings, and transmission systems for material transport

- Collaborative Robots (Cobots): Lightweight drive trains with precise torque control for safe human-robot interaction

- Mobile Robotics: Differential drive systems, steering mechanisms, and wheel encoders for autonomous navigation

- Warehouse Automation: High-speed conveyor drives, sortation systems, and robotic picking stations

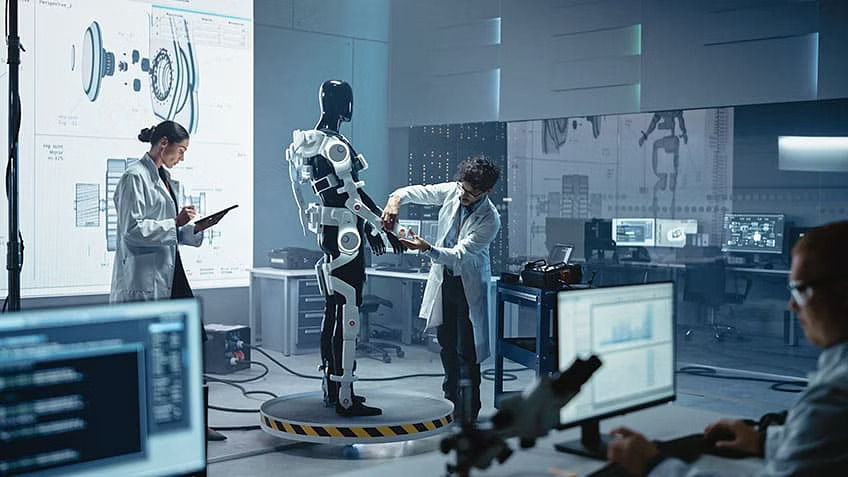

- Exoskeleton Systems: Precision joint actuators and power transmission for wearable robotics

- Agricultural Robots: Rugged drive components for autonomous tractors and harvesting equipment

- Defense & Tactical Robots: Military-grade drive trains for reconnaissance and bomb disposal robots

E. Why Choose Yicen Precision for Drive Train Components?

Yicen Precision brings specialized expertise in manufacturing complex drive train components with fast turnaround times suitable for both prototype development and high-volume production. Our engineering support includes comprehensive Design for Manufacturability (DFM) consultation, helping optimize gear ratios, material selection, and heat treatment specifications for your specific robotic application. We maintain complete material traceability with certified mill test reports and heat treatment documentation for every component. Our scalable manufacturing capabilities handle orders from single prototypes to thousands of production units with consistent quality standards. Advanced inspection equipment including gear measurement systems, CMMs, and surface finish analyzers ensure every drive train component meets your exact specifications. Cost-effective solutions are achieved through optimized machining strategies, efficient material utilization, and strategic partnerships for heat treatment services. Contact us for a custom quote and discover how our precision drive train components can enhance your robotic system’s performance and reliability.