A. What are Power Supply Enclosures?

Power supply enclosures are precision-machined protective housings designed to contain and shield electrical power distribution systems, DC/DC converters, AC/DC power supplies, battery management systems, and associated control electronics in robotic platforms. These enclosures include sealed electrical boxes, ventilated power chassis, rack-mount housings, battery compartments, and integrated control cabinets with thermal management features. They provide environmental protection, electromagnetic interference shielding, thermal regulation through conductive cooling or active ventilation, and secure mounting for sensitive electrical components. Power supply enclosures are critical in industrial robotic cells, autonomous guided vehicles, collaborative robot systems, medical surgical robots, warehouse automation platforms, and aerospace robotics applications. The precision and protective qualities of these machined housings directly impact electrical system reliability, thermal performance, electromagnetic compatibility, safety compliance, and operational longevity across manufacturing, logistics, medical, and defense robotics applications.

B. Key Technical Requirements

Power supply enclosures for robotics demand exceptional precision with tolerances of ±0.002″ to ±0.005″ on mounting surfaces and alignment features to ensure proper component installation and grounding. Flatness specifications on sealing surfaces typically require 0.002″ per linear foot to ensure proper gasket compression and environmental protection rated to IP54, IP65, or NEMA 4X standards. Wall thickness specifications must balance structural rigidity, weight constraints, and thermal conductivity requirements, typically ranging from 0.125″ to 0.250″ depending on size and application. Material specifications must provide adequate electrical conductivity for proper grounding and EMI shielding effectiveness, typically requiring less than 1 ohm resistance between mounting points. Surface finish requirements range from Ra 63 to Ra 125 microinches on external surfaces with special attention to sealing groove dimensions of ±0.005″ for O-ring compatibility. Thermal management features including heat sinks, cooling fins, and ventilation openings require precise geometries to achieve specified thermal dissipation rates, often exceeding 100 watts. Thread specifications for cable glands and mounting hardware must conform to NPT, metric, or PG standards. Enclosures must withstand shock loads, vibration across 10-500 Hz, and environmental exposure including moisture, dust, chemicals, and temperature extremes from -40°F to 185°F.

C. Manufacturing Challenges & Solutions

Machining power supply enclosures presents complex challenges including maintaining dimensional accuracy across large, thin-walled structures susceptible to thermal expansion and machining deflection. Complex internal geometries for component mounting, cable routing channels, and thermal management features require multi-axis accessibility and strategic tool path planning. Achieving consistent wall thickness while maximizing internal volume demands precise material removal strategies. Sealing groove dimensions must be exceptionally consistent to ensure proper gasket compression and environmental protection across temperature cycling. Integrated cooling fin arrays require precise spacing and depth control for optimal thermal performance. EMI shielding effectiveness depends on proper surface preparation and grounding continuity across mating surfaces.

Yicen Precision overcomes these manufacturing challenges through advanced 5-axis CNC machining that enables complete enclosure fabrication with minimal setups, ensuring perfect alignment of mounting features, sealing surfaces, and component interfaces. Our CAM software optimizes tool paths for thin-wall machining using adaptive clearing strategies that minimize cutting forces and thermal distortion while maintaining consistent wall thickness. We employ precision fixtures specifically designed for enclosure machining, supporting large structures rigidly while providing access to all features. Integrated thermal analysis during design consultation ensures cooling features are optimized for specific power dissipation requirements. CMM inspection verifies all critical dimensions including wall thickness, flatness specifications, hole positions, and thread quality with documented traceability. Our quality control measures include pressure testing for sealed enclosures, thermal imaging verification for cooling effectiveness, and continuity testing for proper grounding paths, ensuring every power supply enclosure meets exact specifications for optimal electrical protection, thermal management, and environmental sealing.

D. Applications & Use Cases

Power supply enclosures are essential across diverse robotic platforms:

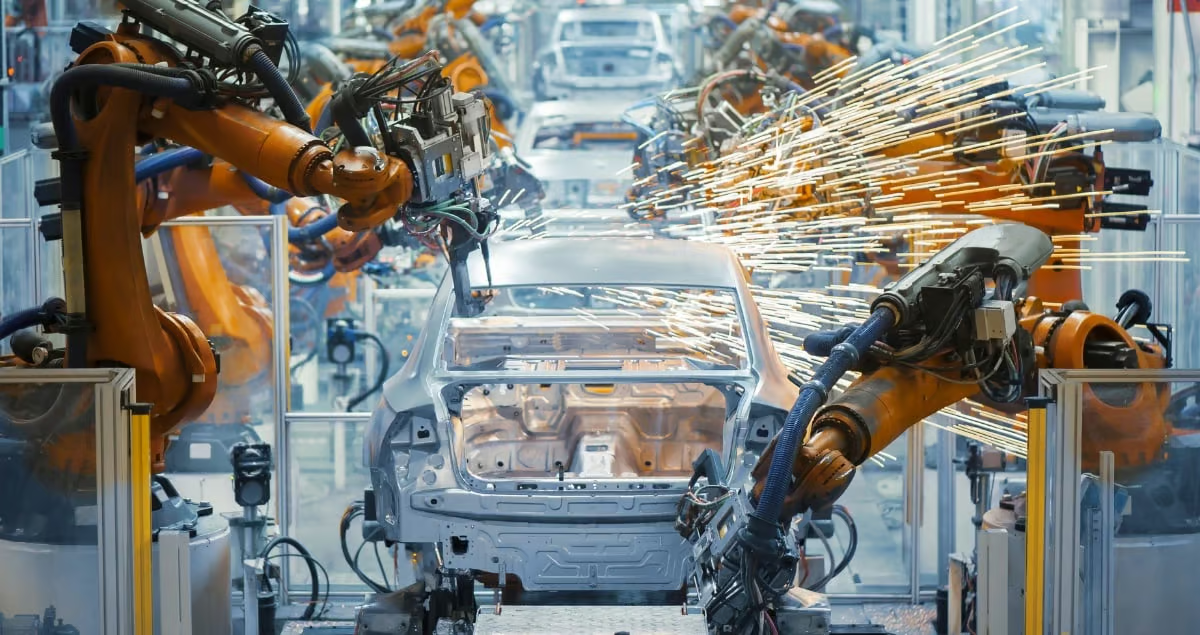

- Industrial Robotic Cells: Main control cabinets and power distribution enclosures for multi-axis robots in manufacturing

- Autonomous Mobile Robots (AMRs): Battery compartments and power management housings for warehouse logistics platforms

- Collaborative Robots (Cobots): Compact power supply enclosures with enhanced safety features for human-robot interaction

- Medical Surgical Robots: Sterile-compatible electrical housings with isolated power systems for operating room environments

- Warehouse Automation: Rugged power enclosures for sortation systems, conveyor controls, and robotic picking stations

- Agricultural Robotics: Weather-resistant power supply housings for autonomous tractors and field monitoring equipment

- Aerospace & Defense: Lightweight, EMI-shielded enclosures for UAV power systems and military ground robots

- Underwater ROVs: Sealed, pressure-resistant power enclosures for submersible robotic inspection platforms

E. Why Choose Yicen Precision for Power Supply Enclosures?

Yicen Precision delivers specialized expertise in manufacturing complex power supply enclosures with rapid turnaround times from prototype development through high-volume production runs. Our engineering team provides comprehensive Design for Manufacturability (DFM) consultation, optimizing enclosure designs for thermal management, EMI shielding, environmental sealing, cable management, and manufacturing efficiency. We maintain complete material traceability with certified mill test reports and material certifications for every enclosure component. Our scalable production capabilities accommodate both custom single-unit enclosures for specialized robotics applications and high-volume production orders with consistent quality standards throughout. State-of-the-art inspection equipment including CMMs, thermal imaging cameras, and electrical continuity testers ensure dimensional accuracy, thermal performance, and proper grounding. We provide additional services including anodizing for enhanced corrosion resistance, powder coating for electrical insulation, and custom surface treatments for specific environmental requirements. Integration capabilities allow us to install threaded inserts, cable glands, and mounting hardware as complete assemblies.