Why a Clear Specification Checklist Matters

Ordering custom jigs and fixtures is a complex process that requires precision and clear communication between engineers and manufacturers. A well-structured specification checklist is essential for avoiding costly mistakes and ensuring your fixture meets its intended function.

Avoiding Redesign, Cost Overruns, and Delays

A well-defined checklist prevents misunderstandings and ensures that all technical requirements are addressed up front, avoiding the need for costly redesigns and delays in the production process. Inaccurate specifications can lead to production stoppages, increased lead times, and inflated budgets, making a detailed checklist an invaluable tool.

Ensuring Correct Functionality from First Delivery

A clear checklist helps align both the engineer’s expectations and the manufacturer’s capabilities, ensuring that the fixture or jig will perform as required. This guarantees that the first delivery of the custom tool will meet your operational needs, reducing the likelihood of rework.

Improving Communication Between Engineer & Manufacturer

Effective communication is crucial in custom jig and fixture design. A clear checklist ensures that engineers and manufacturers are on the same page regarding material, design features, tolerances, and functionality, minimizing misunderstandings and enhancing the overall efficiency of the process.

Before You Order Define Your Jig & Fixture Requirements

1. Purpose of the Jig/Fixture

Operation Type: Drilling, Machining, Welding, Assembly

Begin by clearly defining the primary function of the jig or fixture. Are you creating a fixture to hold a part during machining (e.g., milling, turning), drilling, or welding? The intended operation will dictate the design, clamping systems, and material selection.

Required Level of Automation (Manual, Semi-Auto, Full-Auto)

Decide whether the fixture will be manual, semi-automated, or fully automated. Automated fixtures are typically more complex and expensive but offer higher productivity and repeatability, especially in high-volume environments.

Single-Operation or Multi-Operation Fixture

Is your fixture designed for a single operation, like drilling one hole, or is it a multi-operation fixture that will perform various tasks, such as milling, drilling, and assembly? Multi-operation fixtures require more intricate designs but can save time in production, making them highly valuable for complex manufacturing processes.

2. Workpiece Details

Material, Hardness, Shape, Surface Finish

Provide detailed information about the workpiece to ensure the fixture can handle its material and geometry. For example, hard materials may require fixtures made from tougher materials like tool steel or hardened steel, while softer materials like aluminum may allow for simpler, lighter fixtures.

3D CAD Models + Detailed Drawings

If available, include 3D CAD models or detailed 2D drawings of the workpiece. These models will help the manufacturer understand how the workpiece fits into the fixture and ensure that tolerances and locating points are accurately defined.

Workpiece Tolerances (Critical Dimensions, Datums)

Clearly outline the critical dimensions and tolerances that the fixture must support. Include important datums and any critical-to-quality (CTQ) dimensions that the fixture must maintain for the manufacturing process to be successful.

3. Production Volume & Usage Frequency

Prototype, Low-Volume, or Mass Manufacturing

The production volume will influence the design and material selection of your fixture. A prototype fixture may be made from less durable materials, while fixtures for mass manufacturing must be made from stronger, more wear-resistant materials to withstand the rigors of high-volume production.

Temporary vs Long-Term Fixture

Is the fixture intended for a one-time task or short-run production (temporary) or designed for long-term use in continuous production? Long-term fixtures require more robust construction and higher investment but pay off in terms of durability and reliability over time.

Expected Wear and Replacement Intervals

How often do you expect to replace or maintain the fixture? Fixtures for high-wear applications may require frequent maintenance or replacement, so consider wear-resistant materials like hardened steel or tool steel for critical areas.

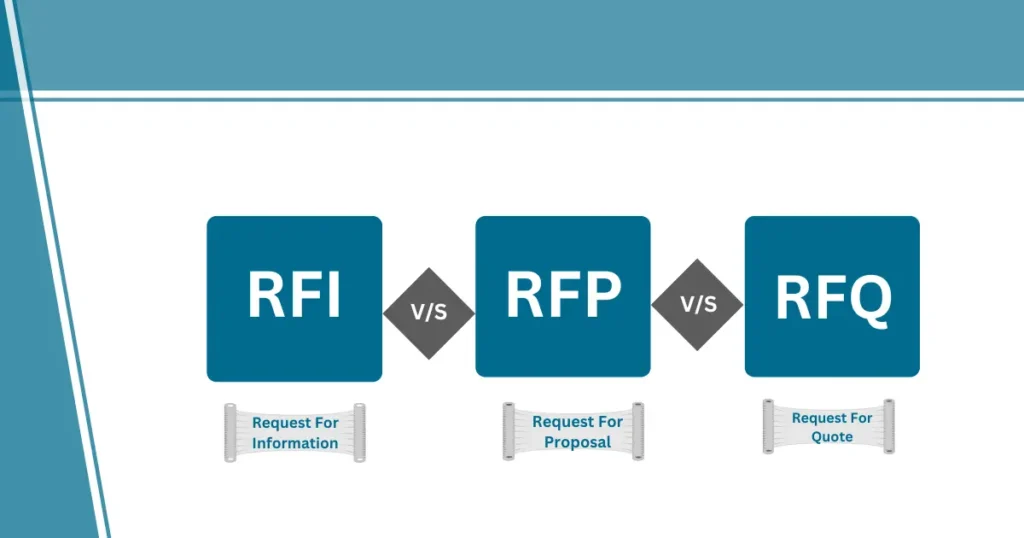

Technical Specifications to Include in Your RFQ

4. Locating Requirements

Primary, Secondary, Tertiary Datums

Define the locating requirements based on the workpiece’s geometry. Specify the primary, secondary, and tertiary datums to establish clear reference points for the fixture. This ensures precise positioning and alignment of the workpiece.

Locator Type (Pins, V-Blocks, Rest Pads, Adjustable Locators)

Choose the type of locators that best suit the part’s geometry, such as pins, V-blocks, or rest pads. Adjustable locators may be necessary if your fixtures will accommodate multiple part shapes or sizes.

Allowable Repeatability Error

Define the tolerance for repeatability. High-precision operations may require a fixture that ensures sub-millimeter accuracy, while lower-tolerance operations may be less stringent.

5. Clamping Requirements

Clamping Type (Manual, Hydraulic, Pneumatic, Magnetic, Vacuum)

Specify the type of clamping system required. For heavy-duty applications, hydraulic or pneumatic clamping may be needed, while lighter fixtures may rely on manual or magnetic clamping systems.

Clamping Force Requirement

Determine the clamping force required to hold the workpiece in place during machining without causing distortion or damage to the material.

Avoiding Part Distortion

Consider the design of the clamping system to prevent part distortion during clamping. Use soft jaws, padding, or shim systems to minimize deformation on delicate parts.

6. Tooling & Guiding Needs

Drill Bushings, Guide Plates, Stops

Specify whether the fixture needs any specialized tool guides, such as drill bushings or guide plates, to ensure the cutting tools are correctly aligned during operation.

Alignment Tolerances

State the alignment tolerances required for the tool and workpiece. High-precision applications will require tighter tolerances, whereas lower-precision operations will be more forgiving.

Tool Accessibility, Chip Clearance

Ensure that the fixture design provides adequate tool accessibility and chip clearance for the machining process. Without sufficient clearance, chips can build up and interfere with the cutting process, reducing efficiency.

7. Material & Construction Preferences

Aluminum, Steel, Tool Steel, Hardened Components

Specify your material preferences based on the fixture’s expected usage. Aluminum is lightweight and corrosion-resistant, while tool steel or hardened components offer strength and durability for high-wear applications.

3D Printed Components (for Low Load)

For low-load applications, consider using 3D-printing components, which are cost-effective for producing prototypes or one-off fixtures without compromising on design complexity.

Corrosion Protection & Surface Finishing

For fixtures exposed to harsh environments, specify corrosion-resistant materials or surface treatments like anodizing, coating, or plating to prolong the fixture’s life.

8. Ergonomics & Operator Safety

Part Loading Height

Ensure that the fixture design allows for an ergonomic part loading height, reducing operator strain and fatigue during frequent part handling.

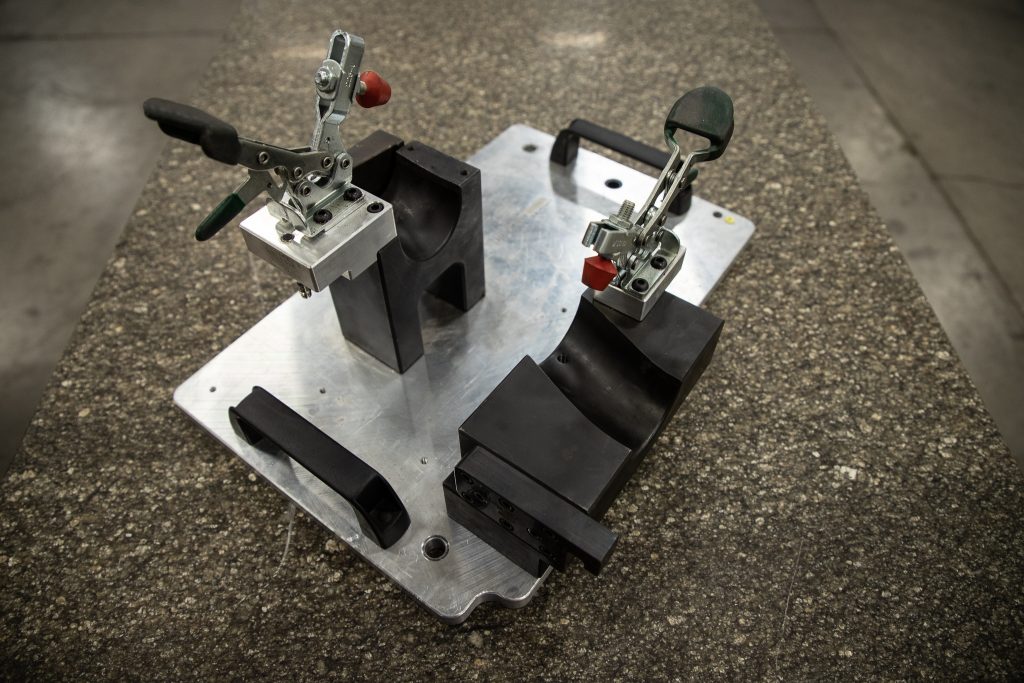

Handles, Grips, Safety Shields

If necessary, specify the inclusion of handles, grips, or safety shields to ensure ease of handling and protect operators from injury during operation.

Fool-Proofing & Mistake-Proofing

Design features that prevent operator errors, such as fool-proofing mechanisms (e.g., guide pins or locking mechanisms) to ensure parts are loaded correctly every time.

Operator Visibility and Accessibility

Ensure that the design allows operators to see critical components of the fixture for monitoring during setup and operation, reducing the likelihood of errors and improving overall efficiency.

Manufacturing Considerations (What to Communicate Clearly)

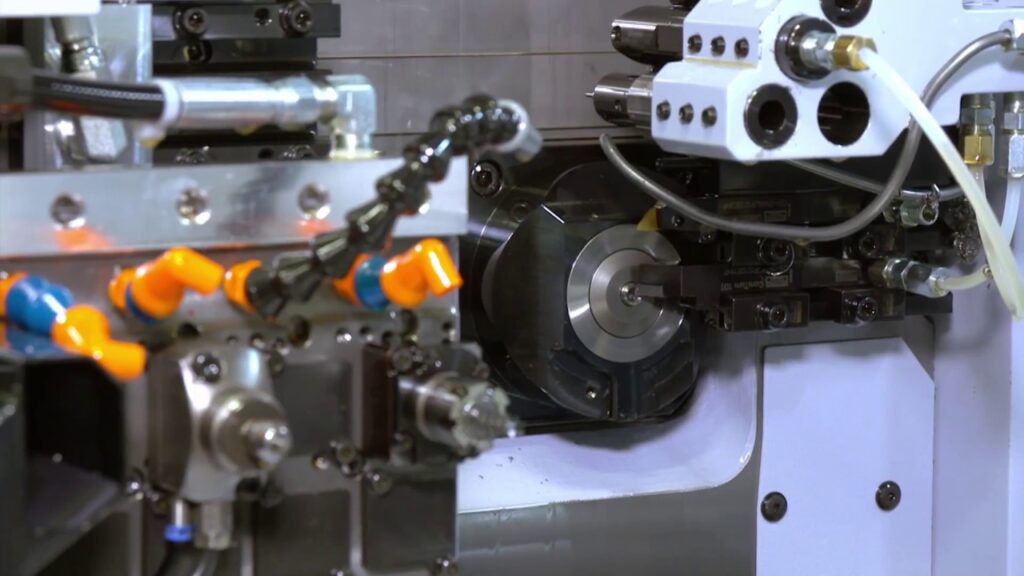

9. Machine Compatibility

CNC Machine Size

Ensure that the fixture is compatible with the CNC machine size, particularly for automated or multi-operation fixtures that require proper alignment with the machine’s setup.

Spindle Clearance

Ensure there is enough spindle clearance for the tool to access the workpiece and perform operations without interference from the fixture.

Fixture Mounting (T-slot, Grid Plate, Custom Base Plate)

Specify the mounting system for the fixture, whether it be a T-slot, grid plate, or custom base plate for secure fixture attachment.

10. Tolerance Requirements

Positional Tolerance

Define the positional tolerance for the workpiece within the fixture. This determines the accuracy with which the fixture will hold the workpiece during machining operations.

Flatness/Parallelism

Specify any flatness or parallelism tolerances required to ensure the workpiece is held accurately and consistently.

Repeatability Expectations

Clarify the repeatability expectations, especially in high-precision applications where the fixture must provide consistent results across multiple production cycles.

11. Preferred Manufacturing Method (If Any

CNC Machining

Specify if the fixture should be manufactured using CNC machining for high precision.

Welding + Fabrication

If your fixture requires custom fabrication, welding may be necessary, especially for large or heavy-duty fixtures.

3D Printing

For prototypes or low-volume production, 3D printing can be an excellent choice due to its flexibility and cost-effectiveness.

Hybrid (CNC + Additive)

A hybrid approach combining CNC machining and 3D printing can be used for high-precision components with complex geometries.

12. Inspection & Validation Requirements

CMM Inspection

Specify if CMM (Coordinate Measuring Machine) inspection is needed to verify the fixture’s dimensional accuracy.

Dry-Run Testing

Ensure that the fixture is tested in a dry-run scenario to ensure proper functionality before full production.

Load Testing

If applicable, specify whether load testing is required to assess the fixture’s ability to handle operational forces.

Assembly Check Reports

Request assembly check reports to verify that the fixture meets your assembly requirements.

Project Management Checklist

13. Timeline & Delivery Expectations

Standard Lead Time vs Urgent Requirement

Specify whether you have a standard lead time or if the fixture is needed urgently for a production deadline.

Prototype Stage, Revision Cycles

Clarify if a prototype is needed before full production and the number of revision cycles anticipated.

Pilot Testing Before Mass Production

If required, specify pilot testing to ensure the fixture performs as expected before moving to full-scale production.

14. Budget Constraints

Preferred Cost Range

Provide a preferred cost range to guide manufacturers in proposing solutions that fit your budget.

Cost-Saving Options (Modular, Standard Components)

Ask for modular designs or the use of standard components to reduce costs while maintaining functionality.

Trade-Offs Between Precision and Price

Consider and communicate trade-offs between precision and price to balance costs and manufacturing needs.

15. Documentation You Should Provide

3D CAD Files (STEP/IGES)

Include 3D CAD files in industry-standard formats like STEP or IGES to facilitate accurate manufacturing.

2D Drawings with Tolerances

Provide 2D drawings with detailed tolerances for critical features and dimensions.

Process Sheet (If Any)

Include a process sheet if available, detailing any specific steps or considerations during the manufacturing process.

Photos/Videos of Real Workpiece Setup

Provide photos or videos of the actual workpiece setup to ensure the fixture is designed to fit accurately.

What to Ask Your Manufacturer Before Ordering

Experience with Similar Fixtures

Inquire if the manufacturer has experience with similar fixtures, especially for complex or high-precision operations.

Examples/Case Studies They Can Share

Ask for case studies or examples of previous work to assess their capabilities and the quality of their work.

Do They Offer DFMA (Design for Manufacturing Assistance)?

Check if they offer Design for Manufacturing Assistance (DFMA) to help optimize the fixture design for ease of manufacturing and cost-effectiveness.

Warranty, Support & Iteration Policy

Clarify the warranty terms, support availability, and their iteration policy for revisions during production.

After-Sales Service Availability

Ensure that the manufacturer offers after-sales services, including maintenance or modifications after the fixture is delivered.

Final Pre-Order Checklist (Printable Summary)

Purpose

Before placing an order, clearly define the purpose of the jig or fixture. What task will it perform in the manufacturing process? The fixture could be designed for holding, clamping, locating, or supporting a workpiece during machining or assembly. The purpose will heavily influence the design, material choice, and features required. Is it for high-volume production or a single prototype? Does it need to be adjustable, or should it hold the workpiece rigidly for precision?

Workpiece Information

Provide detailed specifications of the workpiece that will be held by the jig or fixture. This includes the geometry, size, weight, and any features (e.g., holes, grooves, or surface finishes). If possible, provide CAD models or drawings for reference. Knowing the exact workpiece details helps the designer choose appropriate clamping methods, locating pins, and adjustability features. For instance, larger workpieces may require more robust fixtures, while smaller ones may need more delicate handling.

Tolerances

Tolerances refer to the acceptable limits of variation for the workpiece dimensions and alignment during machining. Precise tolerance requirements will determine the design and material of the fixture. For high-precision work (e.g., aerospace or medical parts), fixtures must be designed with tight tolerances to ensure the workpiece is held in exact alignment. Discuss the tolerance range for each critical feature of the part to ensure the fixture supports the required precision.

Clamping

Clamping ensures the workpiece is held securely during machining or assembly. Specify the type of clamping system required: manual, pneumatic, hydraulic, or automated. For some workpieces, adjustable clamps may be necessary to accommodate variations in shape. The choice of clamping method should minimize distortion, vibration, and any other factors that could compromise the part’s accuracy. Clamping force must also be considered to ensure the part is held tightly but not deformed.

Locating

Locating refers to how the workpiece is positioned within the fixture to ensure repeatability and accuracy. Locating features such as pins, v-blocks, or reference surfaces should be chosen based on the part’s geometry. Provide the key locating points and ensure they correspond to the workpiece’s critical features. If the part has multiple sides or faces, the fixture should allow for easy rotation or repositioning to achieve consistent and accurate results across all faces.

Material

Choose an appropriate material for the jig or fixture based on the workpiece’s material, required durability, and environmental factors. Common materials include mild steel, aluminum, stainless steel, and tool steels. Aluminum may be chosen for lighter parts and faster setup times, while tool steel is preferred for heavy-duty fixtures requiring durability under high stresses. Also, consider whether the fixture needs heat resistance, corrosion resistance, or the ability to withstand heavy forces.

Machine Compatibility

Ensure the fixture is compatible with the machine being used, whether it’s a CNC machine, manual mill, lathe, or assembly line. Consider factors such as machine bed size, spindle orientation, and the type of tooling that will be used. A fixture designed for a CNC machine might require mounting systems like zero-point clamping to improve repeatability. Check for any specific machine limitations or requirements that could affect fixture design, such as clearance space or tool accessibility.

Safety

Safety should be a primary concern in the design of the jig or fixture. The fixture should be designed to prevent any movement of the workpiece during machining that could cause a safety hazard. Ensure that the clamping system is secure and that there is minimal risk of part ejection. All sharp edges should be avoided or rounded off, and the fixture should not obstruct any critical machine safety features (e.g., guards or interlocks). Consider operator safety during setup, adjustments, and operation.

Budget

Set a clear budget for the jig or fixture design and manufacturing. Include material costs, labor for design and machining, and any additional accessories like clamping systems or special tooling. It’s important to consider long-term value, including fixture lifespan, ease of maintenance, and potential for reuse or modification for future parts. Ensure that the cost fits within your overall production cost constraints without sacrificing essential features like accuracy or durability.

Timeline

Define the timeline for the design and delivery of the custom jig or fixture. Depending on complexity, lead times can range from a few weeks to a few months. Determine the urgency of your order and communicate it clearly with your supplier or manufacturer. Timely fixture delivery is essential to avoid production delays. Make sure the fixture’s design is completed with enough time for any required testing or adjustments before full-scale production.

Inspection

Decide how the finished fixture will be inspected for quality. Will the fixture undergo dimensional checks using CMM (Coordinate Measuring Machine) or manual methods like micrometers? Specify any tolerances for the fixture’s critical dimensions, such as locating pins, clamping surfaces, and the overall alignment. Discuss whether in-process inspections are needed for parts being held in the fixture, such as probing or measuring devices integrated into the fixture design.

Documentation

Proper documentation is essential for traceability, maintenance, and future design modifications. Ensure that all drawings, CAD files, and specifications are included with the fixture. This documentation should detail all features, dimensions, material specifications, clamping methods, and instructions for use. It should also include maintenance guidelines and any certifications (e.g., for compliance with industry standards). Documentation is essential for future repair, modifications, or even creating identical fixtures for larger production runs.

Prototype Testing

Consider building a prototype or pilot version of the fixture before final production. This helps in evaluating its performance under actual working conditions and can reveal unforeseen issues like part fitment, clamping force issues, or inaccuracies in locating. A prototype allows for adjustments before committing to mass production.

Ease of Use and Setup

Evaluate how easy the fixture will be to use in production. An efficient fixture should minimize setup time, which is critical for high-volume production. It should be intuitive for operators to use, with simple adjustment mechanisms and quick workpiece loading and unloading. Having a user-friendly design can significantly reduce machine downtime and improve overall productivity.

Conclusion

A well-defined specification checklist ensures that your custom jigs and fixtures meet both operational needs and budget constraints. Proper planning helps reduce costs, avoid delays, and ensure the fixture will function correctly from the first delivery. Clear communication, thoughtful design, and careful consideration of all technical and operational requirements will save time and money, ultimately leading to a more successful manufacturing process.

FAQS

What should be considered when ordering custom jigs and fixtures?

When ordering custom jigs and fixtures, consider the part’s material, complexity, precision requirements, production volume, and machine compatibility. Additionally, ensure you have clear specifications regarding tooling, setup time, and durability. Reviewing the design for ease of use and maintenance is also crucial.

How do I determine the right material for a custom jig or fixture?

The right material for a custom jig or fixture depends on factors like the part material, expected load, wear resistance, and thermal properties. Common materials for jigs and fixtures include mild steel for general purposes, aluminum for lighter loads, and high-strength steel for heavy-duty applications. The material choice should balance cost and durability.

How do I ensure my custom jig and fixture will be compatible with my machinery?

To ensure compatibility, provide the fixture designer with detailed specifications of your machines, including tool sizes, spindle types, and the work envelope. Also, consider how the fixture will be mounted or held on the machine, ensuring alignment with the machine’s tooling and capabilities.

What are the cost factors to consider when ordering custom jigs and fixtures?

Cost factors include the complexity of the design, material choice, required precision, the volume of parts to be produced, and the type of machinery used. Custom designs that require advanced features or high precision may cost more, while simpler, standardized fixtures will be more cost-effective.

How important is precision in custom jigs and fixtures?

Precision is critical in custom jigs and fixtures to ensure parts are held securely and correctly during machining. High-precision fixtures are essential for tight tolerances, repeatability, and minimizing errors. Inaccurate fixtures can lead to part defects, scrap, or machine downtime.